Introduction

Press fitting ISO15875 have revolutionized modern plumbing by offering a fast, reliable, and leak-proof method of connecting pipes. These fittings use a specialized press tool to create secure connections without the need for soldering, threading, or welding, making them ideal for a wide range of applications.

What Are Press Fittings?

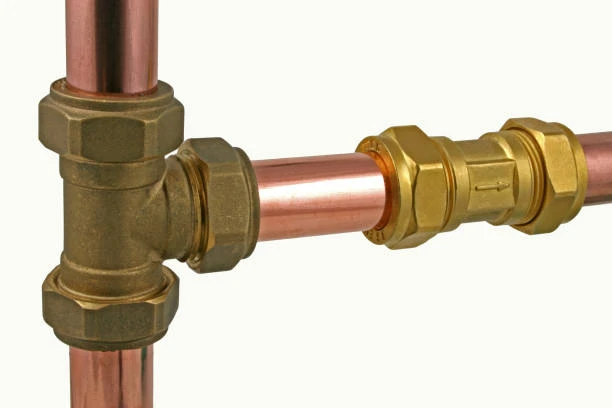

Press fittings are pipe connectors that use mechanical pressing to join pipes together. The press fitting system consists of a fitting, typically made from materials like copper, stainless steel, or brass, and a press tool that crimps the fitting onto the pipe. This creates a durable, watertight seal that can withstand high pressure and temperature.

Advantages of Using Press Fittings

1. Faster Installation

One of the biggest advantages of press fittings is the speed of installation. Unlike traditional methods that involve soldering or welding, press fittings can be installed in seconds, which reduces labor time significantly.

2. No Open Flame

Since press fittings don’t require heat or flames, they are safer to use in environments where an open flame could be dangerous. This eliminates the risk of fire and is particularly useful in confined spaces or near flammable materials.

3. Leak-Proof Connections

The press-fit method ensures a secure, leak-proof seal. The consistent pressure applied during crimping prevents leaks and ensures long-term reliability in plumbing systems.

4. Versatility

Press fittings can be used in various types of plumbing systems, including potable water, gas, and HVAC systems. They are available in a wide range of materials, including copper, stainless steel, and PEX, to suit different applications.

Common Applications of Press Fitting

1. Residential Plumbing

Press fittings are widely used in residential plumbing for both new installations and repairs. Their quick installation and reliability make them a preferred choice for connecting water supply lines, heating systems, and more.

2. Commercial and Industrial Systems

In larger buildings, press fittings are used in high-pressure systems such as heating, ventilation, and air conditioning (HVAC), as well as fire sprinkler systems. Their ability to handle both high temperatures and pressures makes them ideal for industrial applications.

3. Gas Lines

Press fittings designed for gas systems offer a secure, flame-free way to connect pipes, making them an excellent choice for natural gas and propane installations.

How Press Fittings Work

Press fittings use a simple yet effective mechanical process to create a sealed connection. Here’s how they work:

- Prepare the Pipe: First, cut the pipe to the desired length and ensure the edges are clean and free of debris.

- Insert the Pipe into the Fitting: Slide the pipe into the press fitting until it reaches the stop point inside the fitting.

- Press the Fitting: Use a specialized press tool to crimp the fitting onto the pipe. The tool applies uniform pressure around the fitting, creating a watertight seal.

- Inspect the Connection: After pressing, check the connection to ensure the fitting is securely crimped and the seal is tight.

Why Choose Press Fitting Over Traditional Methods?

1. No Need for Soldering or Welding

Press fittings eliminate the need for soldering or welding, which saves time and reduces the risk of heat damage to surrounding areas. This makes them especially useful in settings where open flames are a safety concern.

2. Reduced Downtime

For commercial and industrial systems, using press fittings can significantly reduce downtime.

3. Reliability Under Pressure

Materials Used in Press Fitting

Press fittings are available in several materials, each suited to different applications:

- Copper: Ideal for water supply and heating systems, copper press fittings offer excellent corrosion resistance and durability.

- Stainless Steel: Used in commercial and industrial applications, stainless steel press fittings are highly resistant to corrosion and are ideal for harsh environments.

- Brass: Suitable for potable water systems, brass press fittings offer a balance of strength and corrosion resistance.

Conclusion

Press fittings have become a go-to solution for modern plumbing systems. Their speed of installation, reliability, and versatility make them a smart choice for both residential and commercial applications. Whether you’re installing a new plumbing system or upgrading an existing one, press fittings offer a safe, efficient, and leak-proof alternative to traditional pipe connections.