Introduction

AmeriTex, a leading player in the concrete pipe manufacturing industry, is set to diversify its offerings by launching production of High-Density HDPE pipes. This strategic move marks a significant shift from its traditional focus on concrete pipes and reflects broader industry trends favoring plastic pipes due to their versatile applications and numerous benefits. This article explores the reasons behind AmeriTex’s decision, the advantages of HDPE pipes, and what this expansion means for the industry.

AmeriTex: A Snapshot

Company Overview

AmeriTex has established itself as a prominent manufacturer of concrete pipes, known for producing durable and reliable products for various infrastructure projects. The company’s expertise in concrete technology has earned it a solid reputation in the construction sector.

The Expansion to HDPE Pipe Production

Why Transition to HDPE?

AmeriTex’s decision to add HDPE pipes to its product line is driven by several factors:

Market Demand: There’s increasing demand for plastic pipes due to their flexibility, resistance to corrosion, and ease of installation.

- Product Diversification: Expanding into HDPE pipes allows AmeriTex to cater to a broader range of applications and capture a larger market share.

Advantages of HDPE Pipes

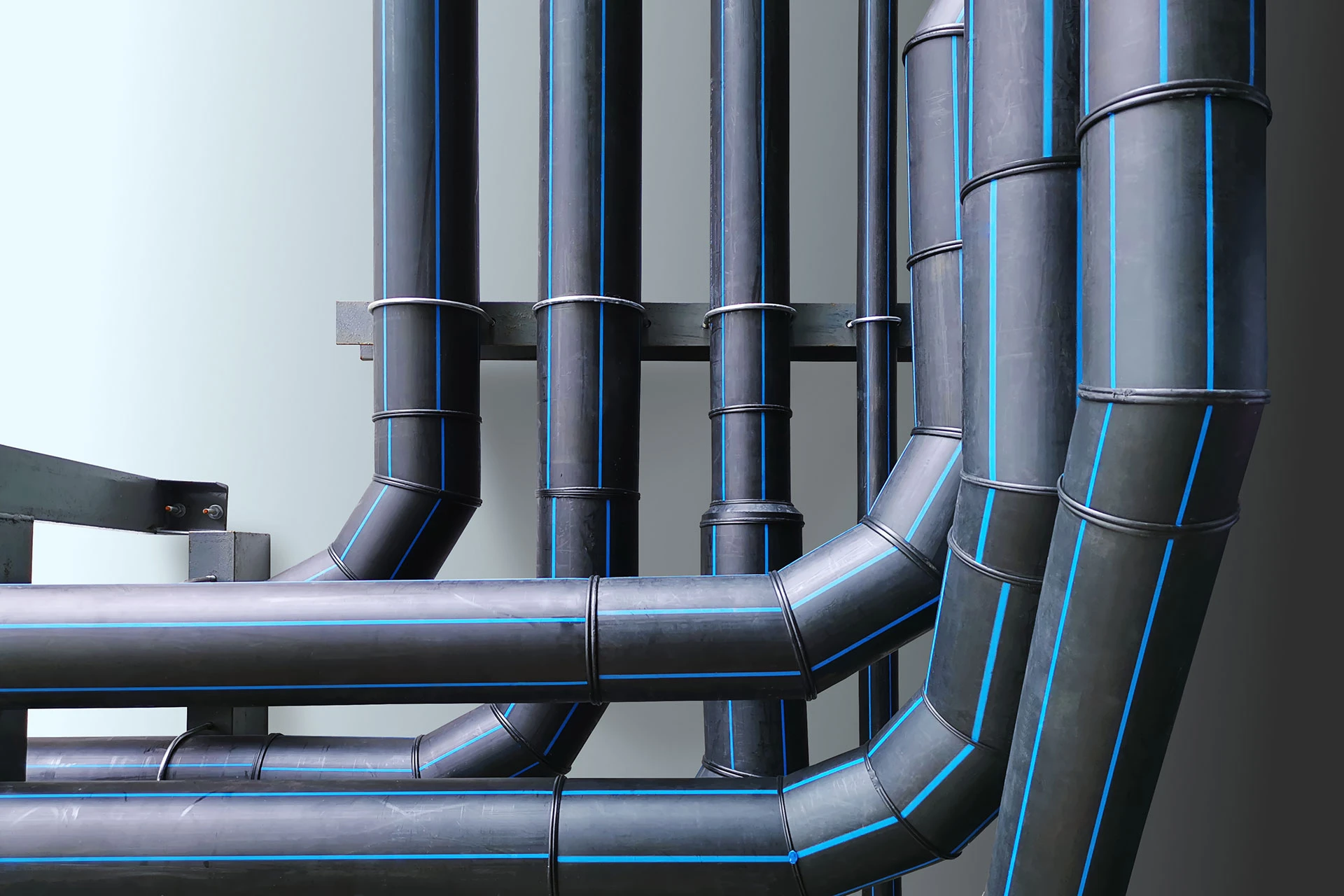

High-Density Polyethylene (HDPE) pipes offer several benefits that make them an attractive alternative to traditional concrete pipes:

- Durability: HDPE pipes are resistant to impacts, abrasions, and various chemicals, which makes them suitable for harsh environments.

- Longevity: With a service life often exceeding 50 years, HDPE pipes reduce the need for frequent replacements, offering long-term cost savings.

Production Process for HDPE Pipes

Manufacturing Overview

The production of HDPE pipes involves several key steps:

- Extrusion: HDPE resin is melted and extruded through a die to form the pipe. This process ensures the pipe has a consistent diameter and wall thickness.

- Cooling: The extruded pipe is cooled using water or air to solidify it. Proper cooling is essential to maintain the pipe’s integrity and dimensional accuracy.

Impact on the Industry

Effects on the Concrete Pipe Market

AmeriTex’s entry into the HDPE pipe market is likely to influence the concrete pipe industry in several ways:

- Increased Competition: The introduction of HDPE pipes adds new competition, potentially driving innovation and impacting market prices.

- Broadened Product Offerings: The expanded product line will provide customers with more options, catering to diverse needs and preferences.

Opportunities for Growth

The expansion presents several growth opportunities for AmeriTex:

- Access to New Markets: By offering HDPE pipes, AmeriTex can tap into markets and applications that prefer plastic over concrete solutions.

- Enhanced Customer Base: The addition of HDPE pipes allows AmeriTex to attract new clients and serve existing ones with a broader range of products.

AmeriTex’s New Facilities

Facility Upgrades

To support the production of HDPE pipes, AmeriTex is investing in new facilities:

- Advanced Extrusion Equipment: The new facilities will feature state-of-the-art extrusion technology to produce high-quality HDPE pipes.

- Enhanced Quality Assurance Labs: Upgraded laboratories will ensure thorough testing and validation of the pipes’ performance.

Environmental Considerations

- Recycling Initiatives: The company plans to implement recycling processes to handle waste material from HDPE pipe production.

- Energy Efficiency: New facilities will incorporate energy-efficient technologies to minimize environmental impact.

Future Outlook

Innovation and Development

Looking forward, AmeriTex aims to:

- Invest in R&D: Focus on research and development to improve HDPE pipe technology and explore new applications.

- Expand Market Reach: Continue to explore new markets and expand the use of HDPE pipes in various sectors.

Strategic Partnerships

AmeriTex may seek strategic partnerships to:

- Enhance Supply Chain: Collaborate with raw material suppliers to ensure a consistent supply of high-quality HDPE resin.

- Improve Distribution: Partner with distribution networks to increase market penetration and customer accessibility.

Conclusion

AmeriTex’s decision to launch HDPE pipe production marks a significant shift in its business strategy, reflecting the growing demand for versatile and cost-effective piping solutions.

FAQs

Why is AmeriTex moving into HDPE pipe production?

AmeriTex is expanding into HDPE pipe production to meet rising demand for plastic pipes, which offer advantages like flexibility, durability, and cost savings.

What impact will AmeriTex’s expansion have on the pipe industry?

The expansion will introduce new competition, broaden product offerings, and provide additional growth opportunities in the plastic pipe market.

What are AmeriTex’s future plans regarding pipe production?

AmeriTex plans to invest in research and development, expand its market reach, and explore strategic partnerships to enhance its HDPE pipe production capabilities.