Polypropylene Random Copolymer (PPR) pipes have emerged as one of the leading solutions for water transportation in both residential and industrial settings. Their durability, corrosion resistance, and easy installation make them a popular choice. As the demand for PPR water pipe fittings continues to grow, manufacturers around the world are innovating to meet consumer needs. This article delves into the landscape of PPR water pipe fitting manufacturers, providing insights into the industry’s growth, major players, and factors to consider when choosing a supplier.

Introduction to PPR Water Pipe Fittings

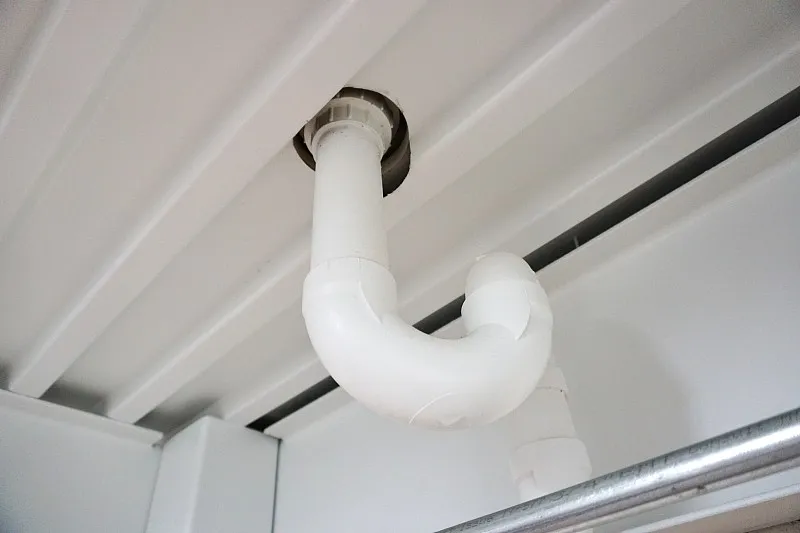

PPR water pipe fittings are an essential part of modern plumbing systems, particularly for hot and cold water supply. These fittings, made from polypropylene random copolymer, are preferred due to their ability to withstand high pressure and temperature, making them ideal for household and industrial use.

Advantages of PPR Water Pipe Fitting

- Durability: PPR fittings are highly durable, resistant to wear and tear, and can last for over 50 years under normal conditions.

- Corrosion Resistance: Unlike metal pipes, PPR fittings do not rust or corrode, making them ideal for both acidic and alkaline environments.

- Heat and Pressure Resistance: These fittings can handle high temperatures (up to 95°C) and high pressure, which is especially important for hot water systems.

- Eco-Friendly: PPR is a recyclable material, making it a greener option compared to traditional metal pipes.

The Global Market for PPR Water Pipe Fittings

The global market for PPR water pipe fitting is expanding rapidly due to the growing construction and infrastructure sectors. The rise in demand for efficient water management systems and sustainable plumbing solutions has further boosted the growth of this market.

Key Market Drivers

- Urbanization and Industrialization: The rapid growth of urban areas and industries has driven the demand for reliable water transportation systems, spurring the need for PPR pipe fittings.

- Technological Advancements: Innovations in manufacturing techniques, such as fusion welding, have made PPR fittings even more efficient and easy to install.

- Environmental Concerns: The increasing focus on eco-friendly building materials has led to a shift towards PPR pipes, which are non-toxic and recyclable.

Top PPR Water Pipe Fitting Manufacturers

Several leading manufacturers dominate the PPR water pipe fitting industry. These companies have built their reputation on quality, innovation, and reliability. Here’s a look at some of the top players:

1. Wavin Group

Wavin is a global leader in plastic pipe systems, including PPR water pipes and fittings. The company has a broad portfolio that caters to various industries, and its products are known for high performance and sustainability.

2. Aquatherm

Aquatherm is a pioneer in PPR pipe production and is known for its innovative solutions for heating, cooling, and potable water supply. The company’s PPR fittings are manufactured to withstand extreme conditions, making them a trusted choice worldwide.

3. Uponor

Uponor is another leading name in the plumbing and heating sectors. While they are renowned for their PEX pipe systems, their PPR products have also gained significant recognition for their durability and efficiency in water supply systems.

4. Georg Fischer (GF Piping Systems)

Georg Fischer is a Swiss multinational company specializing in piping systems. Their PPR water pipe fittings are designed for use in both hot and cold water systems, and the company places a strong emphasis on sustainability.

5. Zhejiang Weixing New Building Materials Co., Ltd.

This Chinese manufacturer is a major player in the PPR water pipe fitting market. Known for producing cost-effective and high-quality products, Zhejiang Weixing caters to both domestic and international markets.

Factors to Consider When Choosing a PPR Water Pipe Fittings Manufacturer

Choosing the right manufacturer for PPR water pipe fitting is crucial for ensuring the longevity and efficiency of your plumbing system. Here are some factors to keep in mind:

1. Quality Standards

Always ensure that the manufacturer adheres to international quality standards such as ISO, ASTM, or DIN. These certifications guarantee that the fittings meet rigorous safety and performance criteria.

2. Product Range

A good manufacturer will offer a wide range of PPR pipe fittings, including elbows, tees, reducers, and couplings, to meet various plumbing requirements.

3. Innovation

Look for manufacturers that invest in research and development. Companies that focus on innovation are more likely to provide advanced, high-performance fittings that can improve the efficiency of your plumbing system.

4. Price vs. Quality

While price is an important factor, it should not compromise quality. Always balance the cost of the fittings with their durability and performance to get the best value for your money.

5. Customer Support

Manufacturers that provide robust customer support and after-sales services are invaluable. They can offer guidance on installation, maintenance, and troubleshooting, ensuring your plumbing system runs smoothly.

How PPR Water Pipe Fittings Manufacturers Impact the Industry

The role of manufacturers in the PPR water pipe fitting industry goes beyond just producing parts. They play a significant role in driving innovation, setting quality standards, and ensuring that plumbing systems worldwide are efficient and sustainable.

1. Setting Industry Standards

Leading manufacturers are often involved in setting international standards for plumbing systems. By ensuring that their products meet these standards, they help improve the overall quality and safety of water systems globally.

2. Reducing Environmental Impact

Manufacturers that focus on producing eco-friendly fittings help reduce the environmental footprint of construction projects. By offering recyclable PPR fittings, they contribute to the sustainability of plumbing systems.

3. Training and Education

Many manufacturers offer training programs for plumbers and contractors. These programs ensure that professionals are well-versed in the latest installation techniques and product innovations, leading to better outcomes in the field.

The Future of PPR Water Pipe Fittings Manufacturing

The future of PPR water pipe fitting manufacturing looks promising, with several trends shaping the industry:

1. Increased Automation

Automation in manufacturing processes is expected to enhance the precision and efficiency of PPR fitting production, leading to higher quality products and reduced costs.

2. Focus on Sustainability

With the global push for more sustainable building materials, manufacturers are likely to invest more in eco-friendly PPR products that minimize waste and energy consumption.

3. Expansion into Emerging Markets

As emerging economies invest in infrastructure development, the demand for PPR water pipe fittings is set to grow. Manufacturers are expected to expand their presence in these markets to capitalize on new opportunities.

Conclusion

PPR water pipe fittings are an essential component of modern plumbing systems, offering durability, efficiency, and environmental benefits. With a growing market and increasing demand for sustainable solutions, manufacturers continue to play a pivotal role in driving innovation and quality in this industry. Whether you’re in need of reliable fittings for a residential or industrial project, choosing the right manufacturer can make all the difference.

5 Frequently Asked Questions (FAQs)

- What are the advantages of using PPR water pipe fittings?

PPR fittings are durable, resistant to corrosion, and can handle high temperatures and pressure. They are also eco-friendly and recyclable. - How long do PPR water pipe fittings last?

Under normal conditions, PPR water pipe fittings can last for over 50 years. - Are PPR water pipe fittings suitable for hot water systems?

Yes, PPR fittings can withstand temperatures up to 95°C, making them ideal for hot water systems. - What certifications should I look for in PPR pipe fittings?

Look for international certifications like ISO, ASTM, or DIN to ensure quality and performance. - Can PPR water pipe fittings be recycled?

Yes, PPR is a recyclable material, which makes it a sustainable choice for plumbing systems.