The HDPE pipe market is poised for substantial growth in the coming years, with projections suggesting a significant increase in demand by 2032. As industries worldwide seek durable, efficient, and environmentally friendly piping solutions, the role of pipe press fittings in these systems becomes increasingly critical. This article delves into the key statistics, driving factors, and market dynamics influencing the HDPE pipe sector, along with the implications for pipe press fittings.

Overview of the HDPE Winding Pipe Market

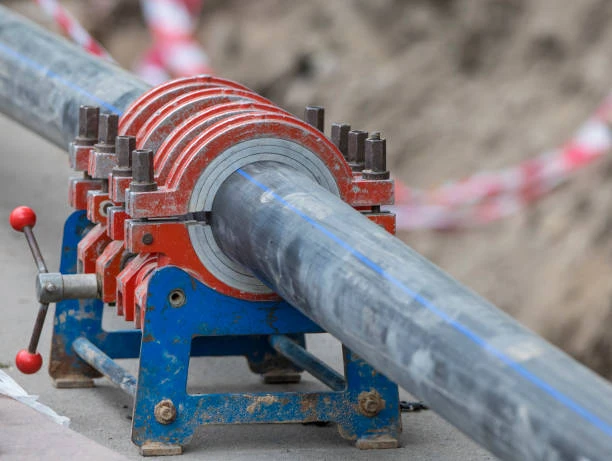

HDPE winding pipes are produced using a spiral winding process, offering unique benefits such as lightweight construction, resistance to corrosion, and flexibility. These pipes are commonly used in applications such as water distribution, sewage management, and industrial processes.

Market Statistics and Projections

According to recent market analyses, the global HDPE winding pipe market is expected to grow at a compound annual growth rate (CAGR) of approximately 6.5% from 2023 to 2032. By the end of this period, the market size is projected to reach around $8 billion, driven by increasing investments in infrastructure, environmental sustainability, and technological advancements.

Key Market Segments

- End-User Industries: The major end-user industries for HDPE winding pipes include municipal water supply, sewage treatment, agriculture, and industrial applications.

- Geographical Trends: North America and Asia-Pacific are expected to lead the market, driven by rapid urbanization and infrastructure development.

- Pipe Diameter: The demand for larger diameter pipes is rising, particularly in water distribution and wastewater management applications.

Factors Driving Global Demand for HDPE Winding Pipes

Several key factors are anticipated to contribute to the growing demand for HDPE winding pipes in the global market.

1. Increasing Infrastructure Development

Rapid urbanization and population growth are prompting significant investments in infrastructure development. Governments and private entities are focusing on improving water supply and sewage systems, creating a strong demand for reliable HDPE piping solutions.

2. Environmental Sustainability

As environmental concerns become more prominent, industries are seeking sustainable alternatives to traditional piping materials. HDPE is recyclable and produces less waste during manufacturing, making it an attractive choice for eco-conscious projects.

3. Durability and Performance

HDPE winding pipes offer exceptional durability, withstanding extreme temperatures and harsh chemicals without degrading. This performance characteristic makes them ideal for various applications, particularly in industries such as agriculture and wastewater management.

4. Cost-Effectiveness

The lightweight nature of HDPE winding pipes simplifies transportation and installation, reducing overall project costs. This cost-effectiveness is a significant factor driving adoption across multiple sectors.

5. Advancements in Technology

Technological innovations in manufacturing processes have enhanced the quality and efficiency of HDPE winding pipes. Improved design and production techniques lead to better performance, making these pipes more appealing to end-users.

The Role of Pipe Press Fittings

As demand for HDPE winding pipes increases, the role of pipe press fittings becomes crucial in ensuring the integrity and efficiency of piping systems.

Advantages of Pipe Press Fittings

- Rapid Installation: Pipe press fittings allow for quick and easy connections, significantly speeding up project timelines.

- Leak-Free Connections: These fittings create permanent seals that prevent leaks, enhancing the reliability of HDPE systems.

- Versatility: Many pipe press fittings are compatible with a variety of materials, including HDPE, allowing for flexibility in design.

- Reduced Labor Costs: The simplicity of installing press fittings leads to lower labor costs, making projects more economically viable.

- Minimal Maintenance: Once installed, pipe press fittings require little to no maintenance, ensuring long-term performance and reliability.

Regional Insights

North America

In North America, the demand for HDPE winding pipes is expected to grow due to increased investments in infrastructure projects and a focus on sustainable practices. The region’s stringent regulations regarding water quality further drive the adoption of durable piping solutions.

Asia-Pacific

The Asia-Pacific region is projected to witness the highest growth rate in the HDPE winding pipe market, fueled by rapid urbanization, population growth, and extensive industrialization. Countries like China and India are investing heavily in water and sewage infrastructure, creating significant opportunities for HDPE manufacturers.

Europe

In Europe, the market for HDPE winding pipes is bolstered by a growing emphasis on environmental sustainability and regulations promoting the use of eco-friendly materials. The region’s aging infrastructure also necessitates the replacement of traditional piping systems with more durable solutions.

Challenges Facing the HDPE Winding Pipe Market

Despite the promising growth prospects, the HDPE winding pipe market faces several challenges that could impact its expansion.

1. Raw Material Price Fluctuations

The price of polyethylene resins can fluctuate significantly due to market demand and supply chain issues. These fluctuations can impact production costs for manufacturers, potentially leading to higher prices for consumers.

2. Competition from Alternative Materials

While HDPE offers many advantages, it faces competition from other materials, such as PVC and metal pipes. The choice of material often depends on specific project requirements and budget constraints.

3. Regulatory Compliance

Navigating the various regulations surrounding the use of HDPE pipes can be complex, especially for manufacturers looking to enter new markets. Ensuring compliance with local standards is crucial for success.

Future Outlook

The future of the HDPE winding pipe market appears bright, driven by increasing demand for sustainable and durable piping solutions. As industries prioritize eco-friendly practices, the adoption of HDPE winding pipes is expected to accelerate.

Emerging Trends to Watch

- Smart Piping Systems: The integration of technology into piping systems, including sensors and monitoring devices, is an emerging trend that can enhance the efficiency and longevity of HDPE pipes.

- Recycling Initiatives: As sustainability becomes a priority, initiatives to recycle HDPE materials will gain traction, reducing environmental impact and promoting circular economy practices.

- Innovative Manufacturing Processes: Advancements in manufacturing technologies will likely lead to improvements in the quality and performance of HDPE winding pipes, further driving market growth.

Conclusion

The HDPE winding pipe market is set for substantial growth by 2032, driven by key factors such as infrastructure development, environmental sustainability, and technological advancements. The integration of pipe press fittings will enhance the overall performance and reliability of these systems, making them indispensable in various applications. As industries increasingly prioritize durable and efficient piping solutions, the future of HDPE winding pipes looks promising.

FAQs

1. What are HDPE winding pipes used for?

HDPE winding pipes are used in various applications, including water distribution, sewage management, agricultural irrigation, and industrial processes.

2. What advantages do pipe press fittings offer?

Pipe press fittings provide quick installation, leak-free connections, versatility, reduced labor costs, and minimal maintenance.

3. How is the HDPE winding pipe market projected to grow by 2032?

The market is expected to grow at a CAGR of approximately 6.5%, reaching around $8 billion by 2032 due to increased demand and infrastructure investments.

4. What challenges does the HDPE winding pipe market face?

Challenges include raw material price fluctuations, competition from alternative materials, and the need for regulatory compliance.

5. How does environmental sustainability impact the HDPE winding pipe market?

Environmental sustainability drives demand for eco-friendly materials like HDPE, as industries seek to minimize waste and reduce their carbon footprint.