One of the materials frequently used in plumbing systems is brass, specifically brass alloys fittings.The quality and safety of drinking water are of paramount concern for both public health authorities and consumers. Ensuring that plumbing components do not introduce contaminants into water systems is essential, and the NSF International (formerly known as the National Sanitation Foundation) plays a significant role in setting the standards for materials that come into contact with drinking water.

Recently, the NSF Standard has confirmed that certain brass alloys fittings meet the required standards for safety and can be classified as acceptable materials for use in drinking water systems. In this article, we will explore the role of NSF standards in regulating materials for potable water, the composition and benefits of brass alloys fittings, and why they are a trusted choice for water systems.

The Role of NSF Standards in Drinking Water Safety

The NSF/ANSI/CAN 61 Standard specifically covers products that come into contact with drinking water, including plumbing fittings, pipes, and other components. It sets stringent guidelines for the materials used in these products, testing for contaminants such as lead, mercury, and volatile organic compounds (VOCs) that could pose health risks if they leach into drinking water.

Brass alloys fittings, which are commonly used in various plumbing applications, have long been under scrutiny due to concerns over the potential for lead leaching. However, with modern manufacturing techniques and alloy compositions that reduce lead content to safe levels, certain brass alloys have been certified as safe for drinking water use according to the NSF Standard.

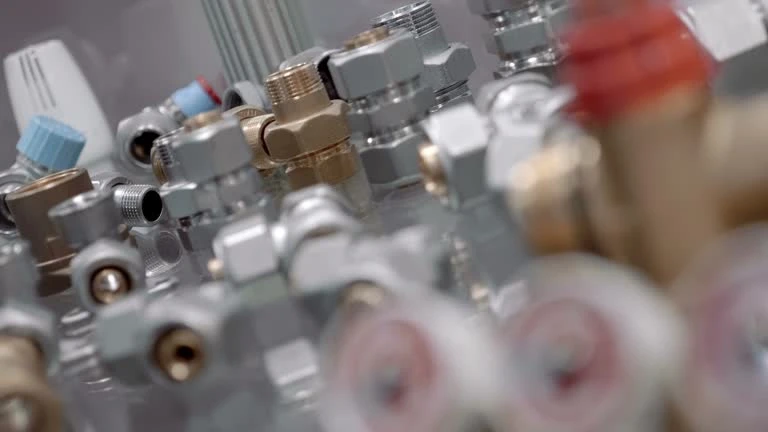

What Are Brass Alloys Fittings?

Brass alloys fittings are plumbing components made from brass, a metal alloy primarily composed of copper and zinc, with small quantities of other metals like lead, tin, or nickel. Brass has been widely used in plumbing systems for centuries due to its durability, resistance to corrosion, and ease of manufacture.

Modern brass fittings are designed to comply with increasingly strict regulations concerning lead content. The Reduction of Lead in Drinking Water Act in the U.S., for example, limits the allowable amount of lead in brass fittings and other plumbing components to a maximum of 0.25% on a weighted average. This has resulted in the development of low-lead brass alloys that are NSF-certified for safe use in drinking water systems.

There are several key benefits of using brass alloys fittings in plumbing systems, especially for potable water:

- Durability: Brass is highly resistant to corrosion, which makes it an ideal material for plumbing systems that are in constant contact with water.

- Thermal Conductivity: Brass has excellent heat resistance, making it suitable for both hot and cold water applications.

- Malleability: Brass can be easily molded and shaped, allowing for the manufacture of a wide range of fittings in different sizes and configurations.

- Reduced Lead Content: Modern brass alloys fittings meet strict regulations on lead content, ensuring that they do not leach harmful levels of lead into drinking water.

The Importance of Brass Alloys in Plumbing Systems

Brass alloys fittings play an essential role in plumbing systems, providing connections between pipes that are both strong and resistant to wear and tear. They are us in various components, such as:

- Valves: Brass valves are commonly found in both residential and commercial plumbing systems, controlling the flow of water.

- Taps and Faucets: Brass is often us in the construction of faucets due to its corrosion resistance and attractive finish.

- Compression Fittings: These fittings are widely us in residential plumbing systems to connect pipes securely, offering a tight seal that prevents leaks.

- Hose Bibbs: Brass is the preferred material for outdoor spigots and hose bibbs due to its ability to withstand the elements and resist corrosion.

Brass alloys have been trust in plumbing for decades because of their ability to withstand exposure to water without degrading. They do not rust like iron or steel, which means that brass fittings have a longer lifespan and are less likely to introduce contaminants into the water system. This is especially important in drinking water applications, where maintaining water quality is critical.

Why NSF Certification for Brass Alloys Fittings Matters

When it comes to plumbing systems, the safety of the materials used is a top priority. Contaminants such as lead, mercury, or other harmful chemicals can leach into the water supply if low-quality materials are us, posing serious health risks to consumers. This is where the NSF certification becomes essential.

The NSF/ANSI/CAN 61 certification ensures that brass alloys fittings meet the required standards for lead content and other contaminants. For brass fittings to be NSF-certifi, they must undergo rigorous testing to ensure that they do not release harmful substances into the water under normal use conditions. This certification gives consumers confidence that the products they are using in their plumbing systems are safe for drinking water.

Advantages of Brass Alloys Fittings for Drinking Water Systems

- Corrosion Resistance: Brass alloys are highly resistant to corrosion, even in environments with varying pH levels or hard water. This makes them ideal for long-term use in potable water systems where exposure to water and fluctuating conditions is inevitable.

- Temperature Tolerance: Brass alloys can withstand both high and low temperatures, making them suitable for both hot water systems and cold water supply lines. This versatility ensures that brass alloys fittings can be us in various applications without compromising performance.

- Lead Compliance: Modern brass alloys meet the strict requirements for low lead content, ensuring they are safe for drinking water. By using NSF-certified brass alloys fittings, property owners and plumbers can be assur that their systems comply with health and safety regulations.

- Cost-Effective: Brass fittings offer an excellent balance between cost and performance. They are more affordable than stainless steel alternatives and, due to their durability, provide long-term value by reducing the need for replacements.

- Ease of Installation: Brass fittings are relatively easy to work with due to their malleability. They can be quickly installed using standard plumbing tools, and their compatibility with various piping materials makes them a convenient option for plumbing professionals.

Why Choose Brass Alloys Fittings for Your Plumbing System?

Choosing the right materials for a plumbing system is critical to ensuring the safety and longevity of the water supply. Brass alloys fittings have a long history of reliable performance in plumbing applications, and with modern low-lead formulations, they are a safer choice for drinking water systems. Here are a few reasons why brass alloys fittings are preferr:

- Compliance with Safety Standards: With NSF certification, brass alloys fittings meet the strictest health and safety standards, ensuring that they are safe for use in systems that supply drinking water.

- Long-Term Durability: Brass’s resistance to corrosion and wear means that fittings last longer, reducing the need for frequent replacements and system repairs.

- Versatility: Whether it’s a residential plumbing system or a large commercial water supply network, brass alloys fittings offer the flexibility to work in various settings, including potable water systems, hot water lines, and even gas distribution networks.

- Aesthetic Appeal: In addition to their functional benefits, brass fittings often have a polished, attractive finish that makes them suitable for visible plumbing installations, such as faucets and fixtures.

Conclusion

The NSF certification of brass alloys fittings as acceptable materials for drinking water systems is a testament to the reliability and safety of these plumbing components. With their durability, corrosion resistance, and compliance with stringent safety standards, brass alloys fittings are a trusted choice for both residential and commercial plumbing applications. Whether you are a contractor, plumber, or homeowner, choosing NSF-certified brass alloys fittings ensures that your water supply remains safe and contaminant-free.

FAQs

- What are brass alloys fitting?

Brass alloys fitting are plumbing components made from a combination of copper and zinc, often with small amounts of other metals like lead or tin. They are us to connect pipes in water systems and offer excellent durability and corrosion resistance. - Are brass alloys fitting safe for drinking water?

Yes, modern brass alloys fitting that comply with NSF/ANSI/CAN 61 standards are consider safe for use in drinking water systems. These fittings have low lead content and are test to ensure they do not leach harmful substances into the water. - What is NSF/ANSI/CAN 61 certification?

This certification a standard set by NSF International for products that come into contact with drinking water. It ensures that materials used in these products, including brass alloys fitting, are safe and do not introduce contaminants into the water supply. - What are the benefits of using brass alloys fitting in plumbing?

Brass alloys fitting are durable, corrosion-resistant, and capable of withstanding extreme temperatures. They are also malleable, making them easy to install, and they meet strict safety standards for use in drinking water systems. - How do I know if my brass fittings are NSF-certifi?

Look for the NSF mark on the product or packaging. This certification ensures that the brass fittings meet the required safety standards for drinking water applications. You can also check the manufacturer’s website or NSF’s database for certified products.