Introduction

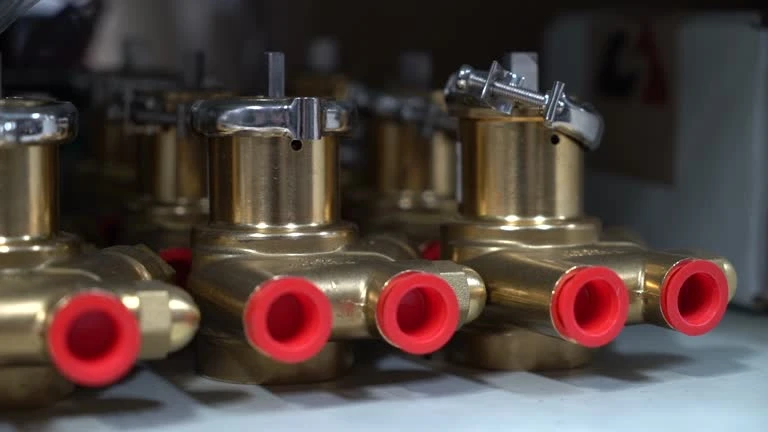

Plumbing is one of the most critical aspects of any building, whether it’s a residential home or a commercial property. The materials used in plumbing, especially copper pipe fittings, play a significant role in the system’s efficiency, durability, and overall cost-effectiveness. Unfortunately, when poor quality copper pipe fittings are used, the results can be disastrous. Leaks, corrosion, and costly repairs are just a few of the problems that can arise, leaving customers frustrated and out of pocket.

In this article, we’ll examine the consequences of using poor quality copper pipe fittings, explore how they can lead to money down the drain for your customers, and highlight the importance of investing in high-quality materials for long-lasting plumbing systems.

The Importance of High-Quality Copper Pipe Fittings

Copper has long been a preferred material in plumbing due to its durability, resistance to corrosion, and ability to withstand high temperatures. However, not all copper pipe fittings are created equal. The quality of the copper used, the manufacturing process, and the precision of the fitting’s design all play a crucial role in the performance of the plumbing system.

- Durability: High-quality copper pipe fittings are known for their longevity, often lasting over 50 years with proper maintenance. When the copper used is of inferior quality, the lifespan of the fittings is significantly reduced, leading to premature failure and costly repairs.

- Corrosion Resistance: Copper is naturally resistant to corrosion. But poor quality copper can contain impurities or may not be treated properly during manufacturing, increasing the risk of corrosion. Corroded fittings can lead to leaks, water damage, and in severe cases, the complete failure of the plumbing system.

- Temperature Tolerance: High-quality copper pipe fittings can withstand extreme temperatures without warping or failing. Inferior fittings may not hold up as well under temperature fluctuations. Causing them to crack or break, which can result in costly repairs.

Consequences of Poor Quality Copper Pipe Fittings

When substandard copper pipe fittings are used in a plumbing system, the consequences are far-reaching. From increased maintenance costs to potential health risks. Here are some of the key issues that arise from using low-quality materials.

- Leaks and Water Damage: One of the most common issues with poor quality copper pipe fittings is leaks. Whether due to improper manufacturing, corrosion. Or poor installation, leaks can quickly lead to water damage in walls, floors, and ceilings. This not only results in costly repairs but can also affect the structural integrity of the building.

- Increased Repair and Replacement Costs: Inferior fittings are prone to failure much sooner than their high-quality counterparts. This means more frequent repairs, replacements, and in some cases, complete overhauls of the plumbing system. Over time, these costs add up, making poor quality fittings a much more expensive option in the long run.

- Reduced System Efficiency: Poor quality copper pipe fittings can affect the efficiency of the entire plumbing system. Leaks, cracks, and blockages can all reduce water pressure, leading to higher energy costs and decreased performance. In commercial settings, this can result in reduced productivity and higher operational expenses.

- Health and Safety Risks: In some cases, poor quality copper pipe fittings can pose health risks. If the fittings are not manufactured to proper standards. They may contain impurities that can leach into the water supply, leading to potential contamination. This is particularly concerning in residential homes where families rely on the plumbing system for clean drinking water.

Why Investing in Quality Copper Pipe Fittings Pays Off

Although high-quality copper pipe fitting may come with a higher upfront cost, the long-term benefits far outweigh the initial investment. By choosing durable, corrosion-resistant, and well-manufactured fittings. You ensure a longer lifespan for the plumbing system and minimize the risk of costly repairs down the road. Here’s why investing in quality pays off:

- Longevity: As mentioned earlier, high-quality copper pipe fitting can last for decades, providing a reliable and efficient plumbing system. This means fewer repairs and replacements, ultimately saving money for your customers over the long term.

- Fewer Leaks: Quality fittings are designed to fit seamlessly into the plumbing system, reducing the risk of leaks. This not only saves on repair costs but also prevents potential water damage that could lead to even more expensive structural repairs.

- Improved Water Pressure and Efficiency: Well-made copper pipe fittings ensure that the plumbing system operates at peak efficiency. This results in better water pressure and a more consistent flow。 hich can reduce energy costs, particularly in commercial settings where water usage is high.

- Peace of Mind: Perhaps most importantly, using high-quality fittings provides peace of mind to both plumbers and their customers. Knowing that the plumbing system is built to last and won’t cause unexpected problems allows everyone to focus on other important aspects of the building’s maintenance.

How to Identify High-Quality Copper Pipe Fittings

Not all plumbers or homeowners may know how to identify high-quality copper pipe fitting, especially when faced with a wide range of options. Here are a few key factors to look for when choosing the best materials for the job:

- Certifications: Look for fittings that meet industry standards and are certified by reputable organizations, such as ASTM (American Society for Testing and Materials) or NSF (National Sanitation Foundation). These certifications ensure that the fittings have been tested for quality and safety.

- Material Composition: High-quality copper fittings should contain at least 99.9% pure copper. Any impurities can weaken the fitting and make it more prone to corrosion and failure.

- Reputation of the Manufacturer: Choose fittings from well-established manufacturers with a reputation for producing durable and reliable products. Reading reviews and asking for recommendations from other professionals can help you make an informed decision.

- Warranty: Reputable manufacturers often offer warranties on their copper pipe fittings, which can give you confidence in their long-term performance. A warranty is a good indicator that the manufacturer stands behind the quality of their product.

Conclusion copper pipe fittings

Using poor quality copper pipe fittings can lead to costly consequences for your customers, from water damage and system inefficiency to health and safety risks. While it may be tempting to save money upfront by choosing cheaper materials, the long-term costs far outweigh the initial savings. High-quality copper pipe fittings offer durability, reliability, and peace of mind, ensuring a plumbing system that lasts for decades without constant repairs.

By investing in quality materials, you can avoid money down the drain and provide your customers with a plumbing system they can trust.

Frequently Asked Questions (FAQ)

- How long do high-quality copper pipe fitting last?

- High-quality copper pipe fitting can last 50 years or more with proper installation and maintenance, making them a durable choice for plumbing systems.

- What are the risks of using poor quality copper pipe fitting?

- Poor quality fittings are prone to leaks, corrosion, and premature failure, leading to costly repairs, water damage, and system inefficiency.

- Can poor quality copper fittings affect water pressure?

- Yes, substandard fittings can lead to leaks and blockages, reducing water pressure and overall system performance.

- How can I tell if copper fittings are of high quality?

- Look for certifications, a high percentage of pure copper (99.9% or more). A reputable manufacturer, and a warranty to ensure high-quality fittings.

- Is it worth investing in high-quality copper pipe fitting?

- Absolutely. While they may have a higher upfront cost, the long-term savings from fewer repairs, leaks. And system failures make them a cost-effective choice in the long run.