Introduction

What are PE Brass Pipe Fittings?

PE brass pipe fittings BS 6572 are essential components in plumbing and construction, designed to connect and seal pipes made of polyethylene (PE) and other materials. Made from a combination of brass and polymers, these fittings offer a durable and reliable solution for various piping systems.

Importance in Plumbing and Construction

In both residential and industrial settings, PE brass fittings ensure secure, leak-proof connections, helping to maintain the integrity of the entire piping system. Their versatility and robustness make them a popular choice for many applications.

Types of PE Brass Pipe Fittings

Compression Fittings

Compression fittings use a compression ring and a fitting body to create a tight seal around the pipe.

Push-to-Connect Fittings

These fittings allow for quick and easy connections without the need for tools or additional sealing materials. Simply push the pipe into the fitting to create a secure connection. They are especially useful in tight spaces and for DIY projects.

Threaded Fittings

Threaded fittings are designed to screw onto pipes, providing a strong and leak-proof connection. They come in various sizes and configurations, making them suitable for many different applications.

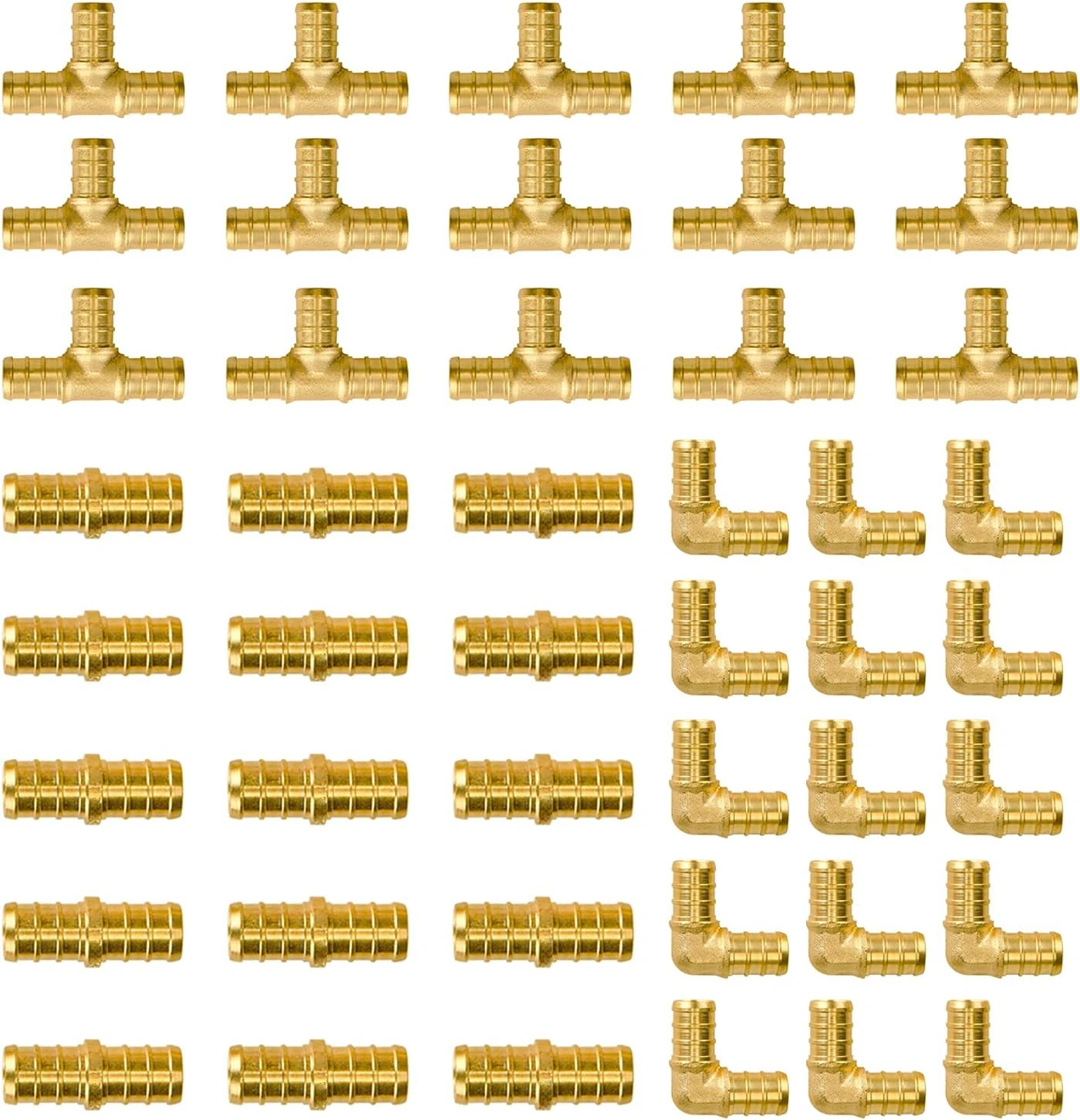

Elbow Fittings

Elbow fittings are used to change the direction of the pipe. Available in various angles (e.g., 45°, 90°), they help navigate around obstacles and create efficient piping layouts.

Tee Fittings

Tee fittings are used to create a branching point in the pipe. They allow for a connection to three different pipes, making them essential for distributing fluid to multiple locations.

Advantages of PE Brass Pipe Fittings

Durability and Longevity

PE brass fittings are known for their durability. Brass is a strong material that withstands physical stress, while the polyethylene component adds flexibility and resistance to cracking.

Corrosion Resistance

Brass is naturally resistant to corrosion, which is a significant advantage in plumbing systems exposed to water and various chemicals. This property ensures a long service life and minimal maintenance.

Ease of Installation

Many PE brass fittings, such as push-to-connect types, are designed for quick and straightforward installation. This ease of use reduces labor time and can lower overall project costs.

Cost-Effectiveness

While brass fittings may have a higher initial cost compared to some alternatives, their durability and low maintenance needs often result in lower long-term costs. This makes them a cost-effective choice in many scenarios.

Applications of PE Brass Pipe Fittings

Residential Plumbing

Their reliability ensures that household plumbing systems function smoothly.

Industrial Uses

Industries often use PE brass fittings in their pipelines for transporting water, chemicals, and other fluids. Their robustness is crucial for handling high-pressure and high-temperature conditions.

Agricultural Systems

Commercial Applications

Commercial buildings, including offices and retail spaces, use PE brass fittings for various plumbing and HVAC applications. Their versatility makes them suitable for a wide range of commercial needs.

How to Choose the Right PE Brass Pipe Fittings

Understanding Pipe Size and Pressure Requirements

Selecting the right fitting starts with knowing the pipe size and the pressure it will handle. Ensure that the fitting you choose matches these specifications to avoid issues like leaks or pipe bursts.

Matching Fittings to Pipe Material

Different fittings are designed for use with specific pipe materials. Make sure that the PE brass fittings you choose are compatible with the type of pipe you are using to ensure a proper seal and fit.

Considering the Environment

Consider the environmental conditions where the fittings will be used. Factors like exposure to chemicals, temperature extremes, and physical stress can impact the performance of the fittings.

Installation Tips for PE Brass Pipe Fittings

Preparing the Pipes

Before installation, ensure that the pipe ends are clean and free of debris. Proper preparation helps achieve a secure and leak-proof connection.

Proper Use of Sealants and Thread Tape

For threaded fittings, use thread tape or sealant to ensure a tight seal. Apply these materials evenly and avoid over-tightening, which can damage the fitting or pipe.

Ensuring Leak-Proof Connections

After installation, check all connections for leaks. Turn on the water supply slowly and inspect each joint. Tighten any connections as needed to ensure a leak-proof system.

Maintenance and Care

Regular Inspection

Regularly inspect your PE brass fittings for signs of wear or damage. Early detection of issues can prevent costly repairs and ensure the continued reliability of your piping system.

Cleaning and Servicing

Keep fittings clean by removing any dirt or buildup. Regular servicing helps maintain their performance and extend their lifespan.

Troubleshooting Common Issues

Common issues with PE brass fittings include leaks and corrosion. Address these problems promptly by tightening connections or replacing damaged parts.

Safety Considerations

Handling and Storage

Handle PE brass fittings carefully to avoid damage. Store them in a dry, cool place to prevent corrosion and ensure their longevity.

Preventing Leaks and Failures

Regular maintenance and proper installation are key to preventing leaks and failures. Follow manufacturer guidelines and industry standards to ensure safe and effective use.

Conclusion

Recap of Key Points

PE brass pipe fittings are essential components for reliable and durable plumbing systems. Their various types and advantages make them suitable for a wide range of applications, from residential to industrial use.

Final Thoughts on PE Brass Pipe Fittings

Choosing the right PE brass pipe fittings ensures that your piping system remains efficient and trouble-free. With their durability, ease of installation, and corrosion resistance, PE brass fittings offer a smart solution for many plumbing and construction needs.