PPR (Polypropylene Random Copolymer) pipes have gained immense popularity in various plumbing and piping applications due to their lightweight, durability, and resistance to corrosion. One of the most critical aspects of any piping system is its ability to withstand pressure. In this article, we will explore how much pressure PPR Pipe can bear, their properties, applications, and factors that influence their pressure ratings.

What are PPR Pipe?

PPR pipes are made from a type of polypropylene, specifically designed to be robust and reliable. They are commonly used for hot and cold water distribution in residential and commercial buildings. Unlike traditional metal pipes, PPR pipes offer several advantages, including:

- Corrosion Resistance: PPR does not rust or corrode, making it ideal for various environments.

- Low Thermal Conductivity: This property helps in reducing heat loss in hot water systems.

- Chemical Resistance: PPR pipes can withstand various chemicals, which makes them suitable for industrial applications.

Pressure Ratings of PPR Pipe

PPR pipes are classified based on their pressure ratings, which determine how much pressure they can handle. The pressure rating is generally indicated in bars (1 bar = 14.5 psi) and is an essential factor when selecting piping for specific applications.

Standard Pressure Ratings

PPR pipes are usually available in different pressure classes, such as:

- PN10: Suitable for a maximum pressure of 10 bars (145 psi).

- PN16: Suitable for a maximum pressure of 16 bars (232 psi).

- PN20: Suitable for a maximum pressure of 20 bars (290 psi).

The choice of pressure rating depends on the intended application, with higher-rated pipes used for more demanding conditions.

Factors Affecting Pressure Resistance

Several factors influence how much pressure PPR pipes can bear, including:

1. Temperature

Temperature plays a crucial role in determining the pressure resistance of PPR pipes. Generally, as the temperature increases, the pressure rating decreases. For example, PPR pipes rated for PN20 at 20°C may only be rated for PN16 at 60°C.

2. Pipe Diameter

The diameter of the PPR pipe also affects its pressure-bearing capacity. Larger diameter pipes tend to have lower pressure ratings than smaller ones, as the wall thickness is proportionally less for larger pipes.

3. Pipe Thickness

The thickness of the pipe walls is another critical factor. Thicker walls provide better pressure resistance. PPR pipes come in various thicknesses, and it is essential to choose the right thickness for the intended application.

4. Quality of Material

The quality of the polypropylene used to manufacture the pipes significantly affects their durability and pressure resistance. High-quality PPR pipes are more likely to withstand higher pressures and last longer.

Applications of PPR Pipe

PPR pipes are widely used in various applications due to their favorable properties:

1. Residential Plumbing

PPR pipes are commonly used for both hot and cold water distribution systems in residential settings. Their resistance to corrosion and scale buildup makes them a reliable choice for household plumbing.

2. Industrial Applications

In industrial environments, PPR pipes are often used for chemical transportation due to their chemical resistance. They can handle a variety of substances without degrading, making them ideal for manufacturing processes.

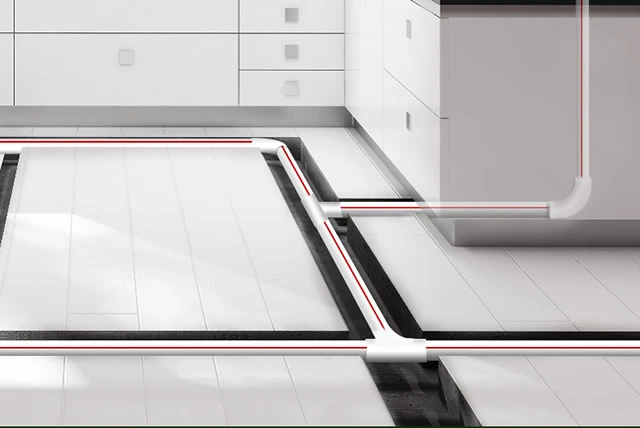

3. Heating Systems

PPR pipes are frequently utilize in heating systems, such as underfloor heating and radiators. Their ability to withstand high temperatures and pressures makes them suitable for these applications.

4. Agricultural Use

In agriculture, PPR pipes are use for irrigation systems, providing a reliable solution for transporting water to crops. Their durability ensures they can withstand the rigors of outdoor conditions.

Installation Considerations PPR Pipe

Proper installation is crucial to ensure that PPR pipes perform to their maximum potential. Some key considerations include:

1. Jointing Techniques

PPR pipes are typically joine using heat fusion techniques. It is essential to follow proper procedures to ensure strong, leak-free joints.

2. Support and Spacing

PPR pipes should be adequately supported to prevent sagging or bending, which can compromise their structural integrity. Proper spacing between supports will depend on the pipe diameter and the application’s requirements.

3. Thermal Expansion

PPR pipes can expand and contract with temperature changes. It is vital to account for thermal expansion during installation to avoid stress on the joints.

Maintenance of PPR Pipe

One of the advantages of PPR pipes is their low maintenance requirements. However, regular inspections can help ensure their longevity. Key maintenance tips include:

- Check for Leaks: Periodically inspect joints and connections for signs of leaks.

- Clean System: Regularly clean the piping system to prevent blockages or buildup.

- Monitor Temperature: Keep an eye on the temperature of the transported fluid to ensure it stays within safe limits.

Conclusion PPR Pipe

PPR pipes are a reliable choice for various applications, with pressure ratings that vary based on several factors, including temperature, pipe diameter, and material quality. Understanding how much pressure PPR pipes can bear is crucial for selecting the right piping solution for your needs. With their durability, resistance to corrosion, and low maintenance requirements, PPR pipes continue to be a popular choice in both residential and industrial settings.

FAQs

- What is the maximum pressure rating for PPR pipes?

- PPR pipes come in various ratings, commonly up to PN20, which can handle up to 20 bars (290 psi) under optimal conditions.

- Can PPR pipes be used for hot water?

- Yes, PPR pipes are suitable for hot water applications, but their pressure ratings decrease at higher temperatures.

- How do I join PPR pipes?

- PPR pipes are typically joined using heat fusion techniques, where the ends of the pipes are heated and then fused together.

- Are PPR pipes resistant to chemicals?

- Yes, PPR pipes have good chemical resistance and can be use for transporting various substances in industrial applications.

- Do PPR pipes require maintenance?

- PPR pipes have low maintenance requirements, but regular inspections for leaks and system cleaning are recommended to ensure longevity.