Introduce PPR Pipe

PPR (Polypropylene Random Copolymer) pipes are renowned for their durability, corrosion resistance, and versatility in plumbing and construction applications. One common question that arises among users and installers is whether PPR Pipe can be glued. This article will explore the topic in-depth, covering the properties of PPR pipes, the appropriate methods for joining them, and the advantages and limitations of using adhesives.

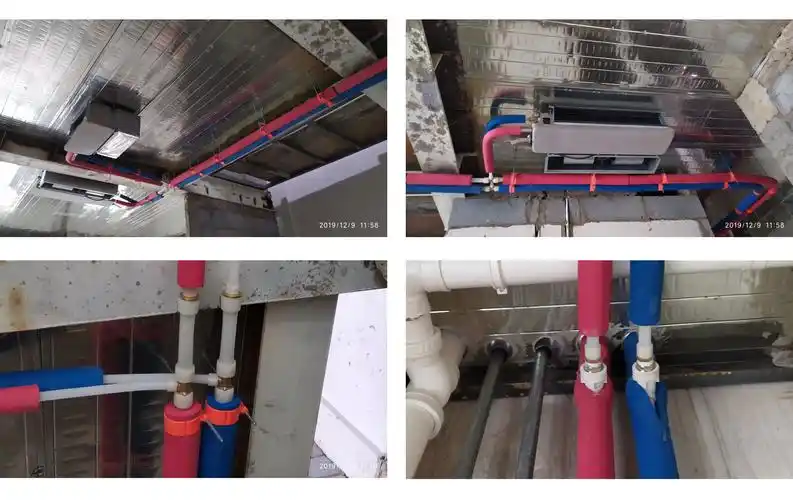

Understanding PPR Pipe

Before delving into the specifics of joining methods, it’s essential to understand the characteristics of PPR pipes. PPR pipes are manufacture from polypropylene, a thermoplastic polymer known for several beneficial properties:

- Corrosion Resistance: PPR pipes do not corrode like metal pipes, making them suitable for a variety of environments.

- Lightweight: Their lightweight nature simplifies transportation and installation.

- Low Thermal Conductivity: PPR pipes are effective in reducing heat loss in hot water applications.

- Chemical Resistance: These pipes can withstand various chemicals, which is advantageous in industrial settings.

Given these properties, PPR pipes are widely use in both residential and industrial plumbing systems.

Joining Methods for PPR Pipe

When it comes to connecting PPR pipes, the method of joining is crucial for ensuring a leak-free and durable system. Unlike PVC or CPVC pipes, which can be joine using solvent cements, PPR pipes are typically joined through the following methods:

1. Heat Fusion

Heat fusion is the most common and recommended method for joining PPR pipes. This technique involves using heat to soften the pipe and fitting ends, which are then presse together to form a strong, permanent bond.

Steps for Heat Fusion:

- Cut the Pipe: Use a proper cutting tool to create a clean, square edge on both the pipe and the fitting.

- Clean the Surfaces: Remove any dirt or debris from the ends of the pipe and fitting.

- Heat the Pipe and Fitting: Use a fusion machine to heat the ends of the pipe and fitting to the appropriate temperature (typically around 260-270°C or 500-518°F).

- Join the Parts: Quickly insert the heated pipe into the fitting, ensuring a proper alignment.

- Hold in Place: Allow the joint to cool for a few minutes to form a strong bond.

This method ensures a reliable joint that can withstand pressure and temperature variations.

2. Mechanical Fittings

In addition to heat fusion, PPR pipes can also be joine using mechanical fittings. These fittings create a seal through screws or clamps without the need for heat.

Steps for Using Mechanical Fittings:

- Prepare the Pipe: Cut the pipe to the desired length and clean the edges.

- Insert into the Fitting: Place the pipe into the mechanical fitting.

- Tighten the Connection: Use the appropriate tools to tighten screws or clamps to secure the connection.

Mechanical fittings are often use in situations where heat fusion is impractical or for temporary connections.

Can PPR Pipe Be Glued?

The short answer is no; PPR pipes should not be glue using traditional adhesives or solvent cements like those used for PVC pipes. Here’s why:

Limitations of Adhesives on PPR Pipe

- Material Composition: PPR pipes are made from polypropylene, which does not bond well with conventional adhesives. Solvent cements that work on PVC cannot effectively adhere to PPR surfaces.

- Heat Resistance: PPR pipes are designe to handle high temperatures, and many adhesives can fail under such conditions, leading to potential leaks and system failures.

- Joint Integrity: Heat fusion creates a molecular bond that is inherently stronger than any adhesive bond. Glued joints are prone to failure under stress or temperature changes.

Alternatives to Gluing PPR Pipe

If you need to connect PPR pipes, the best methods remain heat fusion and mechanical fittings. These techniques ensure a reliable, durable connection that maintains the integrity of the piping system.

Advantages of PPR Pipe Heat Fusion

Using heat fusion to join PPR pipes offers several advantages:

- Strong Joints: Heat fusion creates a homogeneous bond, making the joint as strong as the pipe itself.

- Leak-Proof Connections: Properly fused joints are resistant to leaks, which is critical for plumbing systems.

- Versatility: Heat fusion can be use for various diameters and configurations of PPR pipes.

Maintenance and Inspection of PPR Pipe Joints

Regardless of the joining method used, regular maintenance and inspection of PPR piping systems are crucial for ensuring long-term performance. Here are some tips:

1. Regular Inspections

Inspect joints for signs of leaks or damage. Check fittings and connections periodically to ensure they remain secure.

2. Pressure Testing

After installation, perform a pressure test to verify the integrity of the joints. This is especially important in newly installe systems.

3. Avoid Stress on Joints

Ensure that pipes are properly supporte to avoid undue stress on joints, which can lead to failures over time.

Conclusion PPR Pipe

In summary, while PPR pipes cannot be glued using traditional adhesives, they can be securely joined through heat fusion or mechanical fittings. These methods provide strong, reliable connections that are essential for effective plumbing systems. Understanding the properties of PPR pipes and the appropriate joining techniques will help ensure the longevity and performance of your plumbing projects.

FAQs

- What is the best method to join PPR pipes?

- The best method is heat fusion, which creates a strong, leak-proof bond.

- Can I use PVC glue on PPR pipes?

- No, PVC glue is not suitable for PPR pipes due to material incompatibility.

- How long does it take for heat-fused joints to cure?

- Heat-fused joints typically cool and set within a few minutes, but it’s best to wait longer before applying pressure.

- Are there any special tools required for heat fusion?

- Yes, you will need a fusion machine, which heats the pipe and fitting ends to the correct temperature.

- Can PPR pipes be reused after being heat-fused?

- No, heat-fused joints cannot be reuse. The process creates a permanent bond between the pipes.