In a significant milestone for the fire safety industry, Keraflo has achieved the coveted LPCB (Loss Prevention Certification Board) accreditation for its innovative range of Fire Valves. This accreditation marks a groundbreaking achievement, setting a new standard for quality and safety in fire prevention technology. In this article, we will delve into the importance of fire valves, the significance of LPCB accreditation, and why Keraflo’s products stand out in the market.

Understanding Fire Valves

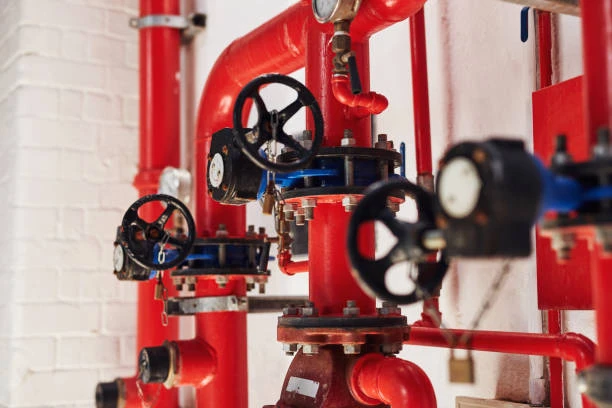

Fire valves play a crucial role in fire protection systems. They are designed to control the flow of water in fire suppression systems, ensuring that water is delivered efficiently to extinguish flames during a fire emergency. Fire valves are vital components of various systems, including sprinkler systems, deluge systems, and standpipe systems.

Types of Fire Valves

- Alarm Check Valves: These valves are used in fire sprinkler systems. They ensure that water flows into the system during a fire, but prevent backflow of water once the fire is extinguished.

- Pressure Relief Valves: These valves help in maintaining the pressure within the fire suppression system, ensuring optimal performance.

- Butterfly Valves: Often used for larger systems, butterfly valves are efficient for controlling flow with minimal pressure loss.

- Gate Valves: These are generally useful for on/off control of the water supply in fire systems.

Importance of Fire Valves

The importance of fire valves cannot be overstate. They are integral to:

- Fire Safety: By ensuring that water is available when needed, fire valves can significantly reduce damage and loss during a fire.

- System Efficiency: Properly functioning fire valves improve the efficiency of fire suppression systems, allowing for quicker response times in emergencies.

- Regulatory Compliance: Many local regulations require the installation of certify fire valves to ensure safety standards are met.

The Significance of LPCB Accreditation

LPCB is a leading certification body that provides testing and certification services for products used in fire safety and security. The LPCB accreditation signifies that a product meets rigorous safety and performance standards, giving users peace of mind.

Why LPCB Accreditation Matters

- Quality Assurance: LPCB-accredited products have undergone extensive testing, ensuring they meet high-quality standards.

- Trust and Reliability: Products with LPCB certification are trusted by professionals in the fire safety industry, making them the preferred choice for installations.

- Regulatory Compliance: Many insurance companies and local authorities require LPCB certification for fire safety products, making it a critical factor in product selection.

- Market Differentiation: Achieving LPCB accreditation sets a company apart from competitors, showcasing their commitment to safety and quality.

Keraflo’s Innovative Approach

Keraflo has long been a pioneer in the design and manufacture of water control products, particularly in the realm of fire safety. With a focus on innovation, reliability, and performance, Keraflo has consistently raised the bar in the industry.

Features of Keraflo’s Fire Valves

- Robust Design: Keraflo’s fire valve are engineer to withstand extreme conditions, ensuring reliability when it matters most.

- Advanced Technology: Incorporating state-of-the-art technology, these valves provide efficient flow control and responsiveness.

- User-Friendly: Designed with the user in mind, Keraflo’s fire valves are easy to install and maintain.

- Sustainability: Keraflo is committe to sustainability, using materials and processes that minimize environmental impact.

The Road to LPCB Accreditation

Achieving LPCB accreditation is no small feat. Keraflo underwent a rigorous testing process, evaluating every aspect of their fire valve, from material quality to performance under stress. This comprehensive assessment ensured that their products met the highest standards of safety and effectiveness.

Implications for the Industry

Keraflo’s achievement has far-reaching implications for the fire safety industry. As the first company to receive LPCB accreditation for fire valve, Keraflo is setting a benchmark for others to follow. This accomplishment is likely to encourage further innovation and improvements in fire safety products across the board.

Industry Impact

- Encouraging Standards: Keraflo’s success may inspire more manufacturers to pursue LPCB accreditation, leading to a higher overall standard in fire safety products.

- Consumer Awareness: With the emphasis on accredited products, consumers are becoming more aware of the importance of choosing certified fire safety equipment, which will drive demand for high-quality, tested products.

- Insurance Benefits: As insurance companies increasingly recognize LPCB accreditation, building owners may benefit from lower premiums for using certified products.

Conclusion

Keraflo’s Fire Valve achieving LPCB accreditation is a landmark event in the fire safety industry. By setting new standards for quality and reliability, Keraflo not only enhances fire safety practices but also paves the way for future innovations in fire protection technology. As industries continue to prioritize safety, the demand for certified, high-quality fire valves will undoubtedly grow, further cementing Keraflo’s position as a leader in the field.

FAQs

- What is the purpose of fire valve?

Fire valves control the flow of water in fire suppression systems, ensuring efficient delivery during emergencies. - What is LPCB accreditation?

LPCB accreditation signifies that a product meets rigorous safety and performance standards, ensuring quality and reliability. - Why is LPCB accreditation important?

It provides quality assurance, builds trust, ensures regulatory compliance, and differentiates products in the market. - What types of fire valves are available?

Common types include alarm check valves, pressure relief valves, butterfly valves, and gate valves. - How does Keraflo ensure the quality of its fire valve?

Keraflo employs robust design, advanced technology, and thorough testing to ensure the reliability and performance of its products.