Introduction

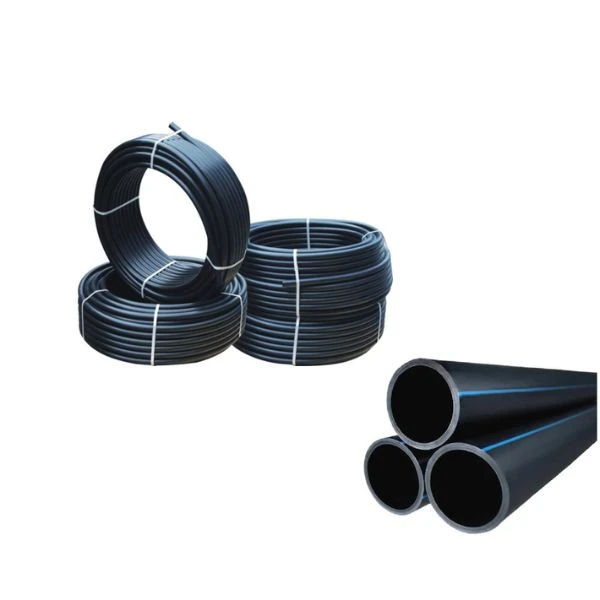

PE pipes are a popular choice for various piping applications due to their flexibility, durability, and resistance to corrosion. This article will delve into the characteristics, advantages, and applications of MDPE and HDPE pipes, helping you understand their distinct roles and how to choose the right type for your project.

What is Polyethylene it?

Key Characteristics

- Flexibility: Both MDPE and HDPE pipes are flexible, which makes them easy to install and adapt to various installation conditions.

- Corrosion Resistance: Polyethylene pipes are resistant to corrosion, making them suitable for use in harsh environmental conditions.

- Chemical Resistance: They can handle a wide range of chemicals, contributing to their longevity and performance in different applications.

MDPE (Medium-Density Polyethylene) Pipes

Definition and Properties

MDPE stands for Medium-Density Polyethylene, which is a type of polyethylene with a density range typically between 0.926 and 0.965 g/cm³.

Characteristics

- Flexibility: PE pipes are more flexible than it, which allows for easier handling and installation in tight spaces.

- Temperature Range: Performs well in a moderate temperature range, typically from -40°C to +60°C.

Applications

- Water Supply Systems: Ideal for potable water distribution due to its durability and resistance to chemicals.

- Gas Distribution: Commonly used for natural gas distribution pipelines because of its ability to handle pressures and resist environmental factors.

- Irrigation Systems: Suitable for agricultural irrigation where flexibility and moderate strength are beneficial.

HDPE Pipes

Definition and Properties

HDPE stands for High-Density Polyethylene, which is a type of polyethylene with a higher density, typically between 0.941 and 0.965 g/cm³.

Characteristics

- Strength and Stiffness: HDPE pipes have higher strength and stiffness compared to MDPE pipes, making them suitable for high-pressure applications.

- Durability: Provides excellent resistance to impact, stress cracking, and environmental stress, ensuring long-term performance.

- Temperature Range: Suitable for a wider temperature range, typically from -40°C to +80°C, depending on the specific grade.

Applications

- Water Supply and Distribution: Used in high-pressure water distribution systems due to its strength and durability.

- Sewer and Drainage Systems: Ideal for sewage and drainage applications because of its resistance to chemicals and high pressure.

- Industrial Applications: Commonly used in industrial settings where high performance and durability are essential.

Comparing MDPE and HDPE Pipes

1. Strength and Durability

- HDPE: Generally stronger and more durable than MDPE, making it suitable for high-pressure applications and harsh environments.

- MDPE: Provides adequate strength for moderate pressure applications and is more flexible than HDPE.

2. Flexibility and Handling

- HDPE: Less flexible compared to MDPE but offers better strength and rigidity.

- MDPE: More flexible, making it easier to handle and install in areas with limited space.

3. Temperature and Environmental Resistance

- HDPE: Better suited for a wider temperature range and harsh environmental conditions.

- MDPE: Performs well in moderate temperatures and environments but may not be suitable for extreme conditions.

4. Cost and Economic Considerations

- HDPE: Typically more expensive due to its higher strength and durability, but offers long-term cost benefits in high-pressure or critical applications.

Choosing the Right Pipe for Your Project

1. Assessing Application Requirements

Consider the following factors when selecting between MDPE and HDPE pipes:

- Pressure Requirements: Choose HDPE for high-pressure applications and MDPE for moderate pressure.

- Environmental Conditions: Select HDPE for harsh or extreme conditions, and MDPE for less demanding environments.

- Flexibility Needs: Opt for MDPE if flexibility is a priority for easy handling and installation.

2. Budget Considerations

Evaluate the initial cost versus long-term benefits.

Ensure that installation practices align with the pipe type.

Conclusion

MDPE and HDPE pipes each offer unique advantages depending on the requirements of your project. By understanding the differences and considering the specific needs of your application, you can make an informed decision that ensures the efficiency and longevity of your piping system.

FAQs

1. Can MDPE and HDPE pipes be used interchangeably?

make them suitable for specific applications. It’s important to choose the pipe type that best fits the requirements of your project.

3. How do I determine the appropriate pipe type for my project?

Consider factors such as pressure requirements, environmental conditions, flexibility needs, and budget when choosing between MDPE and HDPE pipes.

4. Are there any special installation requirements for HDPE pipes?

HDPE pipes often require fusion welding for connections, which may necessitate specialized equipment and training.

5. Can MDPE pipes handle high temperatures?

MDPE pipes are suitable for moderate temperatures but may not perform well in extreme temperature conditions compared to HDPE pipes.