In the dynamic landscape of subsea engineering, the demand for reliable and efficient valve actuation systems has never been higher. Subsea valves play a critical role in oil and gas exploration, as well as in the management of underwater facilities. The introduction of new hybrid concepts for actuating subsea valves is set to revolutionize how these essential components are managed, improving efficiency, safety, and reliability in harsh underwater environments. This article will delve into the importance of subsea valves, the challenges faced in their actuation, and the innovative hybrid solutions currently being developed.

Understanding Subsea Valves

What Are Subsea Valves?

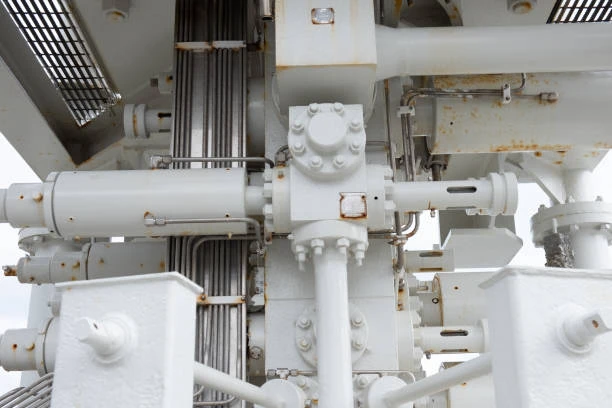

Subsea valves are specialized devices designed to control the flow of fluids (such as oil and gas) in underwater pipelines and facilities. They are crucial for maintaining the integrity of subsea systems, enabling operators to manage production, shut down systems in emergencies, and perform maintenance without the need for extensive intervention.

Types of Subsea Valves

- Ball Valves: Utilized for quick shut-off, ball valves have a spherical disc that allows for smooth flow when open.

- Gate Valves: Known for their ability to provide a straight-line flow, gate valves are often used in large diameter pipelines.

- Check Valves: These prevent backflow, ensuring that fluids only flow in one direction, critical for system safety.

- Globe Valves: Designed for regulating flow, globe valves are ideal for applications requiring fine control.

The Importance of Actuation in Subsea Systems

Why Actuation Matters

The actuation of subsea valves is vital for several reasons:

- Operational Efficiency: Effective actuation ensures that valves respond promptly to commands, enabling smooth operations.

- Safety: In the event of a leak or other emergencies, timely valve closure can prevent catastrophic failures.

- Maintenance: Actuated valves facilitate maintenance operations by allowing for safe isolation of sections of a pipeline or facility.

Traditional Actuation Methods

Historically, subsea valves have been actuated using hydraulic or pneumatic systems. While these methods have been effective, they come with challenges:

- Complexity: Hydraulic systems require extensive infrastructure, making them complex and costly to install and maintain.

- Reliability: In harsh subsea environments, traditional systems can be prone to failure due to corrosion or damage from external forces.

- Maintenance Needs: Regular maintenance is essential for traditional actuation systems, leading to increased downtime and operational costs.

Challenges in Subsea Valve Actuation

1. Harsh Environmental Conditions

Subsea environments are characterize by high pressures, low temperatures, and corrosive conditions. These factors pose significant challenges to the reliability and longevity of valve actuators.

2. Remote Locations

Subsea installations are often located far from shore, making maintenance and repairs logistically challenging and expensive.

3. Energy Consumption

Traditional actuation methods can be energy-intensive, contributing to higher operational costs and impacting the sustainability of subsea operations.

The Hybrid Concept for Actuating Subsea Valves

What is the Hybrid Actuation Concept?

The hybrid concept for actuating subsea valves combines multiple actuation technologies to enhance reliability, efficiency, and responsiveness. By integrating electric and hydraulic systems, this approach leverages the strengths of each method while mitigating their weaknesses.

Key Features of the Hybrid System

- Redundancy: The hybrid system provides backup options in case one actuation method fails, enhancing overall system reliability.

- Improved Response Times: Electric actuation allows for quicker response times, while hydraulic systems provide the power necessary for larger valves.

- Energy Efficiency: The hybrid system can be design to optimize energy consumption, reducing the overall footprint of subsea operations.

- Reduced Maintenance: By minimizing the reliance on complex hydraulic systems, maintenance requirements can be significantly reduce, leading to lower operational costs.

How the Hybrid Concept Works

The hybrid actuation system typically consists of:

- Electric Actuators: These provide precise control over valve movement and can be operate remotely, allowing for quick adjustments.

- Hydraulic Assistance: For larger valves, hydraulic power can be utilized to provide the necessary force for opening and closing.

- Control Systems: Advanced control systems manage the coordination between electric and hydraulic components, ensuring optimal performance and reliability.

Applications of Hybrid Actuation in Subsea Environments

1. Oil and Gas Exploration

In the oil and gas sector, hybrid actuation can enhance the efficiency of subsea production systems. This technology allows for better control of flow rates, optimizing extraction processes while ensuring safety.

2. Renewable Energy

With the growing interest in renewable energy sources, hybrid actuation can also be useful in subsea wind farms and tidal energy installations, providing reliable control of energy transfer systems.

3. Aquaculture

In aquaculture, hybrid actuation can help manage the flow of water and nutrients, improving the efficiency and sustainability of underwater farming practices.

4. Environmental Monitoring

Hybrid actuated valves can be integrate into environmental monitoring systems, allowing for better control of fluid flow in research applications and conservation efforts.

Future Trends in Subsea Valve Actuation

1. Digitalization and Smart Technologies

The integration of IoT and smart technologies in subsea systems is a growing trend. Hybrid actuation systems can benefit from real-time monitoring and analytics, allowing for predictive maintenance and enhanced decision-making.

2. Sustainability Initiatives

As industries push for more sustainable practices, the hybrid concept can contribute to reducing energy consumption and environmental impact, aligning with global sustainability goals.

3. Enhanced Materials

The development of advanced materials that resist corrosion and withstand extreme pressures will further improve the reliability and lifespan of subsea valves and their actuators.

Conclusion

The introduction of a hybrid concept for actuating subsea valves represents a significant advancement in subsea engineering. By combining the strengths of electric and hydraulic actuation, this innovative approach enhances reliability, efficiency, and safety in challenging underwater environments. As the demand for subsea solutions continues to grow, the hybrid actuation system will play a vital role in shaping the future of subsea operations.

FAQs

- What are subsea valves used for? Subsea valves control the flow of fluids in underwater pipelines and facilities, ensuring safe and efficient operations in oil and gas exploration and other applications.

- What is the hybrid actuation concept? The hybrid actuation concept combines electric and hydraulic systems to enhance the performance and reliability of subsea valves, providing improved efficiency and response times.

- What challenges do subsea valve actuators face? Subsea valve actuators encounter challenges such as harsh environmental conditions, remote locations, and high energy consumption.

- What are the benefits of hybrid actuation systems? Benefits include redundancy, improved response times, energy efficiency, and reduced maintenance needs.

- What industries can benefit from hybrid subsea valve actuation? Industries such as oil and gas, renewable energy, aquaculture, and environmental monitoring can all benefit from hybrid actuation systems in their subsea operations.