Introduction

As the demand for efficient water management increases globally, the ability to detect leaks in plastic pipes has become more critical than ever. Leaks not only waste valuable water resources but can also lead to costly repairs and environmental damage. Traditional methods of leak detection often fall short, especially with the growing prevalence of plastic piping in infrastructure. Fortunately, advancements in technology are making detection on plastic pipes more precise and reliable. This article explores the latest innovations in leak detection, their importance, methods employed, and future implications for water management systems.

The Importance of Leak Detection on Plastic Pipes

The Impact of Leaks

Leaks in plumbing systems can have several detrimental effects:

- Water Waste: Estimates suggest that leaks can account for up to 30% of a community’s water supply loss.

- Increased Costs: Higher water bills and the expense of repairs can significantly strain municipal budgets and household finances.

- Structural Damage: Water leaks can lead to soil erosion and damage to buildings and roads.

- Environmental Consequences: Untreated leaks can contaminate local ecosystems, affecting both wildlife and water quality.

The Rise of Plastic Pipes

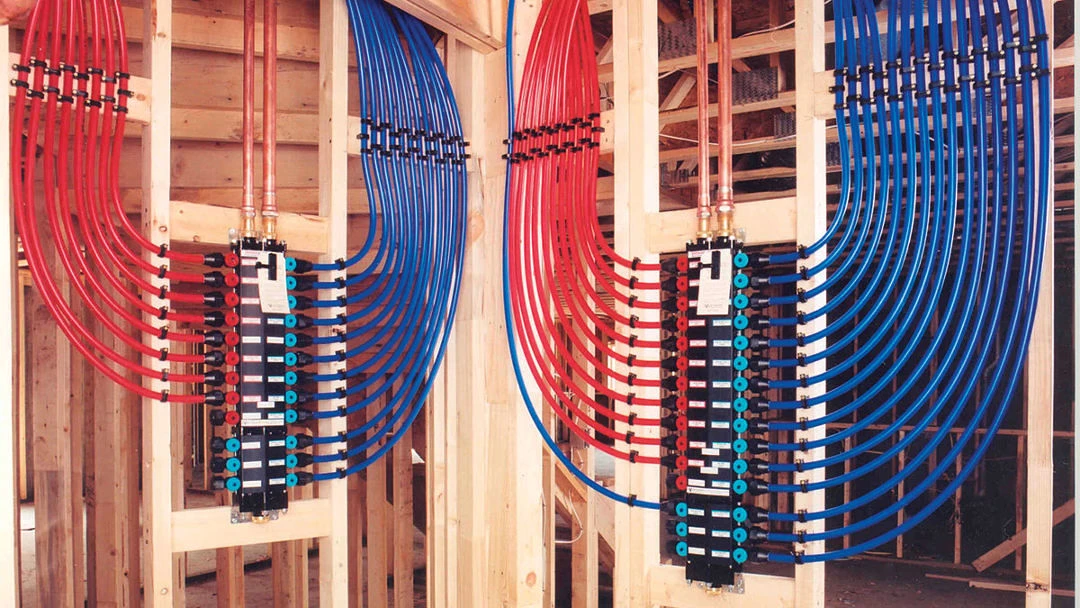

Plastic pipes have become increasingly popular due to their lightweight nature, resistance to corrosion, and ease of installation. Common materials include:

- Polyvinyl Chloride (PVC)

- High-Density Polyethylene (HDPE)

- Cross-Linked Polyethylene (PEX)

While these materials offer many advantages, they also present unique challenges in leak detection. Unlike metal pipes, plastic pipes may not transmit sound waves as effectively, making traditional acoustic methods less effective.

Traditional Leak Detection on Plastic Pipes Methods

Acoustic Detection

Acoustic leak detection involves listening for sounds associated with leaks. While this method can be effective, it has limitations:

- Sensitivity to External Noise: Background noise can interfere with detection accuracy.

- Limited to Certain Pipe Materials: It’s often less effective with plastic pipes compared to metal ones, as sound transmission varies.

Visual Inspections

Regular visual inspections can help identify leaks, but they are labor-intensive and often fail to detect hidden leaks. They also require access to exposed pipes, which isn’t always feasible.

Pressure Testing

This method involves monitoring the pressure within the pipe system to identify drops that indicate leaks. However, pressure testing can be time-consuming and may not pinpoint the exact location of the leak.

Advancements in Leak Detection on Plastic Pipes Technology

1. Smart Sensors

Recent developments in smart sensor technology have revolutionized leak detection on plastic pipes. These sensors can continuously monitor pressure, flow rates, and other variables. Key features include:

- Real-Time Data Monitoring: Sensors provide instant alerts when irregularities are detected, enabling rapid response to potential leaks.

- Remote Access: Many smart sensors can be accessed remotely, allowing for constant monitoring without physical inspections.

2. IoT Integration

The Internet of Things (IoT) allows for the integration of various devices and sensors into a single network. This interconnectedness enhances leak detection in several ways:

- Data Analytics: Advanced algorithms analyze data from multiple sources to identify patterns and predict leak occurrences.

- Automated Alerts: Systems can send automated alerts to maintenance teams, reducing response times significantly.

3. Acoustic Emission Technology

Acoustic emission technology (AET) involves monitoring the high-frequency sound waves produced by leaks. AET is particularly effective for plastic pipes because:

- Sensitive Detection: It can detect small leaks that might be missed by traditional acoustic methods.

- Real-Time Monitoring: AET systems can provide continuous monitoring of pipeline integrity.

4. Ground Penetrating Radar (GPR)

GPR technology uses radar pulses to image the subsurface, allowing for the detection of leaks without excavation. This non-invasive method provides several benefits:

- Location Precision: GPR can pinpoint the exact location of leaks, reducing the need for extensive digging and minimizing disruption.

- Versatility: This method can be used in various terrains and is effective for both above-ground and buried pipes.

Benefits of Advanced Leak Detection on Plastic Pipes

1. Enhanced Accuracy

Modern detection technologies offer greater accuracy in identifying the exact location and severity of leaks, allowing for targeted repairs.

2. Cost Savings

By reducing water waste and minimizing repair costs through early detection, advanced systems can lead to significant long-term savings for municipalities and homeowners alike.

3. Improved Sustainability

Effective leak detection contributes to sustainable water management practices, ensuring that water resources are conserved and responsibly managed.

4. Reduced Downtime

With precise leak detection, maintenance teams can address issues quickly, minimizing service disruptions and ensuring consistent water supply.

Implementation Challenges Detection on Plastic Pipes

1. Initial Costs

While advanced leak detection technologies offer long-term savings, the initial investment can be substantial. This can be a barrier for some municipalities and organizations.

2. Training Requirements

The implementation of new technologies requires proper training for personnel to ensure effective use and maintenance of the systems.

3. Data Management

With the increase in data collection comes the challenge of managing and analyzing that data effectively. Organizations must invest in data analytics tools and trained personnel to leverage the information gathered.

Future Directions in Leak Detection on Plastic Pipes

1. AI and Machine Learning

The incorporation of artificial intelligence (AI) and machine learning into leak detection systems can further enhance predictive capabilities. These technologies can analyze historical data to forecast potential leak risks, allowing for proactive maintenance.

2. Increased Automation

Automation in leak detection will likely continue to grow, enabling systems to self-diagnose and even perform repairs with minimal human intervention.

3. Greater Integration with Smart Cities

As cities evolve into smart environments, the integration of leak detection systems with other infrastructure components—such as traffic management and emergency services—will become increasingly important.

4. Focus on Sustainability

Future developments will likely emphasize sustainable practices, including the use of biodegradable materials for sensors and systems designed to minimize environmental impact.

Plastic Pipes Conclusion

The advancement of detection on plastic pipes marks a significant leap forward in water management practices. With technologies such as smart sensors, IoT integration, and acoustic emission technology, pinpointing leaks has become more accurate and efficient than ever before. These innovations not only conserve valuable water resources but also reduce costs and promote sustainability in infrastructure. As the industry continues to evolve, the focus on smart technologies and data analytics will pave the way for a more resilient and efficient water management system.

FAQs

1. What are the common methods used for detecting leaks in plastic pipes?

Common methods include smart sensors, acoustic emission technology, visual inspections, and pressure testing. Each method has its advantages and limitations.

2. How does IoT improve leak detection on plastic pipes?

IoT enhances leak detection by enabling real-time monitoring and data analytics, allowing for quicker identification of irregularities and automated alerts for maintenance teams.

3. Are plastic pipes more challenging to inspect than metal pipes?

Yes, plastic pipes can be more challenging to inspect using traditional methods, as they may not transmit sound waves as effectively as metal pipes, making advanced technologies essential.

4. What are the benefits of using acoustic emission technology for leak detection?

Acoustic emission technology offers sensitive detection of small leaks and provides real-time monitoring, making it particularly effective for assessing the integrity of plastic pipes.

5. What future trends are expected in leak detection technologies?

Future trends include increased use of AI and machine learning for predictive analysis, greater automation in detection systems, and a focus on sustainability in the development of detection technologies.