Introduction PPR Pipe

PPR (Polypropylene Random Copolymer) pipes have gained popularity in various plumbing applications, particularly for hot and cold water services. This article delves into the suitability of PPR Pipe for these applications, examining their benefits, installation practices, and common concerns.

What is PPR Pipe?

PPR pipe is made from a type of polypropylene that exhibits excellent resistance to temperature and pressure. Known for its durability and versatility, PPR is suitable for both residential and commercial plumbing systems.

Key Characteristics of PPR Pipe

- Temperature Resistance: PPR pipes can withstand temperatures up to 95°C (203°F), making them ideal for hot water services.

- Corrosion Resistance: Unlike metal pipes, PPR does not corrode, ensuring longevity and reliability in plumbing systems.

- Chemical Resistance: PPR pipes are resistant to a wide range of chemicals, making them suitable for various applications beyond just water services.

- Lightweight: Being lightweight, PPR pipes are easy to transport and install.

- Low Thermal Conductivity: PPR pipes minimize heat loss, making them efficient for both hot and cold water distribution.

Advantages of Using PPR Pipe for Hot Water Services

1. PPR Pipe High Thermal Stability

PPR pipes maintain structural integrity even under high temperatures. Their thermal stability reduces the risk of deformation and ensures reliable performance in hot water systems.

2. Energy Efficiency

Due to their low thermal conductivity, PPR pipes can retain heat effectively, reducing energy consumption in heating systems. This characteristic makes them a cost-effective solution for hot water services.

3. Hygienic Properties

PPR pipes do not promote the growth of bacteria, ensuring clean and safe water for domestic and industrial use. Their smooth inner surface prevents sediment build-up, further enhancing hygiene.

4. PPR Pipe Cost-Effectiveness

The initial cost of PPR pipes may be higher than traditional materials, but their durability and low maintenance requirements lead to significant long-term savings.

Advantages of Using PPR Pipe for Cold Water Services

1. Excellent Insulation

PPR pipes offer good insulation properties, minimizing condensation and heat loss. This is particularly beneficial in cold water applications, where temperature control is essential.

2. Versatility in PPR Pipe Applications

PPR pipes are suitable for various applications, including drinking water supply, irrigation, and industrial processes. Their versatility makes them an attractive option for plumbing systems.

3. PPR Pipe Easy Installation

PPR pipes can be easily joined using heat fusion techniques, which ensure a strong, leak-proof connection. This ease of installation translates to reduced labor costs and faster project completion.

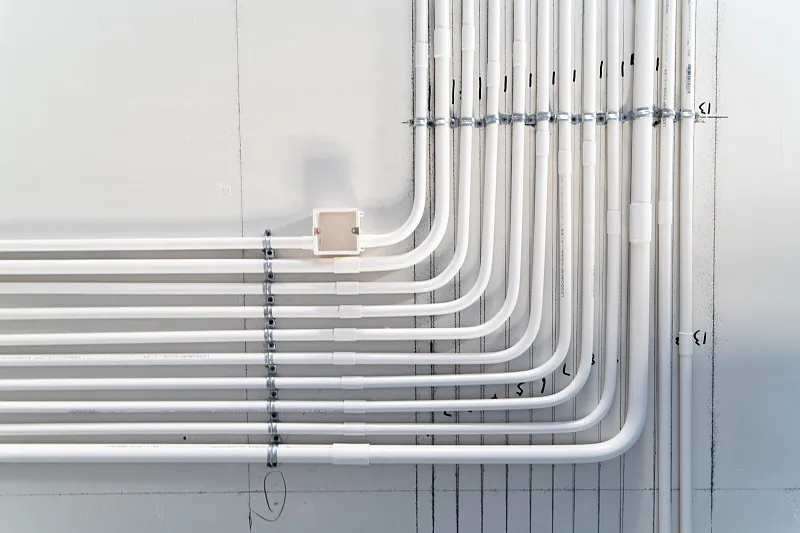

Installation Practices for PPR Pipe

Preparation

Before installation, ensure all tools and materials are ready. PPR pipes require specific fittings and equipment, including a heat fusion machine.

Cutting and Joining

- Cutting: Use a pipe cutter to ensure clean, straight cuts. This helps in achieving a proper fit during the joining process.

- Joining: Heat the ends of the pipes and fittings using a fusion machine until they reach the appropriate temperature. Press them together firmly and hold for a few seconds to allow for proper bonding.

Testing

After installation, perform a pressure test to check for leaks. This step is crucial in ensuring the reliability of the system.

Common Concerns with PPR Pipe

1. Expansion and Contraction

PPR pipes can expand and contract with temperature changes. Proper installation techniques, such as using expansion fittings, can mitigate this issue.

2. UV Sensitivity

PPR pipes can degrade when exposed to direct sunlight for prolonged periods. It’s important to bury them underground or provide adequate shielding in outdoor applications.

3. Compatibility with Other Materials

While PPR pipes are compatible with various materials, care must be taken during transitions. Using appropriate fittings is essential to maintain system integrity.

Conclusion

PPR Pipe are highly suitable for both hot and cold water services due to their durability, thermal stability, and ease of installation. Their numerous advantages make them an excellent choice for modern plumbing applications, whether residential or industrial.

Additionally, PPR pipes are resistant to corrosion and scaling, ensuring a longer lifespan and reduced maintenance costs in various environments.

FAQs

1. Can PPR pipes be used for drinking water?

Yes, PPR pipes are safe for drinking water due to their hygienic properties and resistance to bacterial growth.

2. How long do PPR pipes last?

PPR pipes can last up to 50 years or more with proper installation and maintenance.

3. Are PPR pipes resistant to freezing?

While PPR pipes can withstand low temperatures, they can become brittle if frozen. Proper insulation is recommended in colder climates.

4. Can PPR pipes be used outdoors?

Yes, but they should be protected from direct sunlight to prevent UV degradation.

5. How do you repair PPR pipes?

Repairs can typically be made using heat fusion techniques or by replacing the damaged section with new pipe and fittings.

This comprehensive look at PPR pipes showcases their suitability for hot and cold water services, emphasizing their numerous advantages and practical applications. Whether you are a homeowner or a plumbing professional, PPR pipes present a reliable option for efficient water distribution.