Introduction PPR Pipe

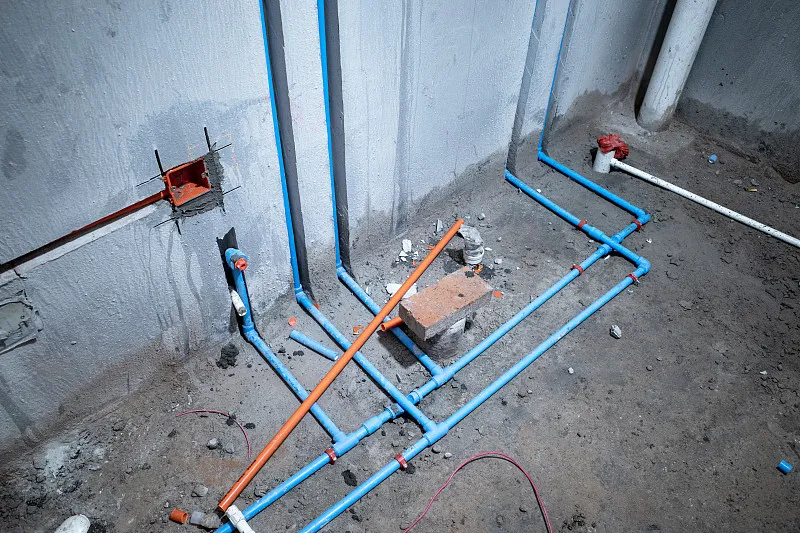

In plumbing systems, both copper pipes and PPR Pipe (Polypropylene Random Copolymer pipes) are incredibly popular materials. They each have their unique benefits and drawbacks, making them suitable for different applications. But what happens when you need to connect the two? While copper has been a standard in plumbing for decades, PPR pipes are increasingly used for water supply and heating systems because of their durability and cost-effectiveness.

Connecting copper pipes and PPR Pipe may seem like a challenge due to their different materials, but with the right tools and methods, it’s entirely possible. In this article, we’ll explore why these two types of pipes are often used together, the challenges of making such a connection, and how to do it successfully.

Understanding PPR Pipe

What Are PPR Pipe?

PPR pipes are made from Polypropylene Random Copolymer, a plastic material that’s highly resistant to heat, chemicals, and corrosion. These pipes are lightweight, flexible, and relatively easy to install compared to traditional metal pipes like copper or steel. PPR pipes are commonly used in water supply systems, heating systems, and even for industrial applications.

Advantages of PPR Pipe in Plumbing Systems

- Durability: PPR pipes are highly resistant to corrosion, scale build-up, and damage from chemicals, making them ideal for long-term use.

- Cost-Effective: Compared to metal pipes like copper, PPR pipes are more affordable.

- Ease of Installation: PPR pipes are lightweight and easy to handle, making installation quicker and simpler than metal alternatives.

- Heat Resistance: PPR pipes can withstand temperatures up to 95°C, making them suitable for both hot and cold water systems.

Understanding Copper PPR Pipe

What Are Copper PPR Pipe?

Copper pipes have been a staple of plumbing for centuries. Made from copper metal, these pipes are prized for their strength, malleability, and resistance to corrosion, particularly when exposed to water. Copper pipes are commonly used for drinking water systems, gas lines, and in heating systems.

Benefits of Using Copper in Plumbing

- Longevity: Copper pipes have a long lifespan (50+ years) when installed correctly.

- Resistant to Corrosion: Copper naturally resists corrosion, especially in water environments.

- High Strength: Copper pipes are sturdy, making them ideal for high-pressure systems.

- Versatility: Copper pipes are suitable for a wide variety of applications, including gas and water distribution.

The Challenges of Connecting Copper and PPR Pipe

Why Connecting These Two Materials Can Be Tricky

Although copper and PPR pipes each offer unique advantages, connecting them together requires careful consideration because they are made from entirely different materials. The primary challenges you might face when connecting copper and PPR pipes include:

- Thermal Expansion: Copper and PPR pipes expand and contract at different rates when exposed to heat, which can result in joint failure if not properly managed.

- Material Compatibility: Copper and plastic don’t naturally bond well, which makes choosing the right fittings and connectors essential.

- Pressure Rating Differences: Copper pipes typically handle higher pressure ratings than PPR pipes, which can lead to potential pressure issues in the system.

Potential Problems with Compatibility

- Corrosion: Direct contact between copper and plastic could lead to galvanic corrosion, weakening the connection over time.

- Leakage: If the joint between the two materials is not properly sealed, it could lead to water leaks, reducing the overall effectiveness of the plumbing system.

Methods of Connecting Copper and PPR Pipe

There are several methods to connect copper and PPR pipes. Below, we’ll discuss the most common types of fittings used to achieve this connection.

Compression Fittings

Compression fittings are often used for joining copper and PPR pipes. These fittings create a tight seal through compression, preventing leaks. They’re relatively easy to install, requiring no soldering or special tools.

Push-Fit Fittings

Push-fit fittings are also very popular. These fittings allow you to connect copper and PPR pipes without the need for special tools. You simply push the pipe into the fitting, and it’s securely connected.

Threaded Fittings

Threaded fittings can be use to connect copper and PPR pipes, particularly in areas where disassembly may be necessary. However, you must ensure that the threads are tightly seale to avoid leaks.

Brazing or Soldering Connections

Brazing or soldering may be use to connect copper pipes, while PPR pipes may require a specific transition fitting to handle heat resistance. These methods require special training and equipment, making them less common for DIY projects.

Transition Fittings

Transition fittings are specifically designe to join two different materials, such as copper and PPR. These fittings have metal on one side and plastic on the other, ensuring a secure connection and preventing issues with thermal expansion or material incompatibility.

Best Practices for Connecting Copper and PPR Pipe

To ensure a successful connection between copper and PPR pipes, follow these best practices:

Proper Pipe Preparation

Before joining the pipes, ensure both copper and PPR pipes are clean and free of debris. For copper pipes, use a wire brush to clean the ends, and for PPR pipes, make sure the ends are cut smoothly.

Selecting the Right Fittings

Always use transition fittings or compression fittings specifically designed for connecting copper and PPR pipes. These will ensure the connection is secure and leak-free.

Importance of Clean and Dry Surfaces

Ensure both pipes are dry and free from oils or contaminants that could interfere with the fitting. This step is critical to ensure a tight, leak-free connection.

Avoiding Pressure Leaks

When using compression or push-fit fittings, make sure the connection is tight. For threaded fittings, ensure the threads are well-lubricated with a pipe thread sealant.

Tools Needed for Copper and PPR Pipe Connections

To connect copper and PPR pipes, you will need the following tools:

- PPR Pipe Cutter: For cutting PPR pipes to the desired length.

- Copper Pipe Cutter: For cutting copper pipes cleanly.

- Fittings and Sealants: Transition or compression fittings, along with pipe thread sealant.

- Wrenches: For tightening compression fittings.

- Deburring Tool: To smooth out edges and prevent damage to the pipe ends.

Installation Steps for Connecting Copper and PPR Pipe

- Prepare the Pipes: Cut both the copper and PPR pipes to the desired length using a pipe cutter.

- Clean the Pipe Ends: Use a wire brush to clean the copper pipe ends and ensure the PPR pipe ends are smooth.

- Attach the Fittings: Use the selected transition or compression fittings to connect the pipes.

- Tighten the Fittings: Ensure the fittings are tightly connecte using a wrench for compression fittings or hand-tightening for push-fit fittings.

- Test for Leaks: After installation, turn on the water supply and check for leaks. If there are any, tighten the fittings further.

Advantages and Disadvantages

Pros of Copper and PPR Pipe Connections

- Versatile and durable

- Lower material costs when combining copper and PPR

- Easier and quicker installation with the right fittings

Cons and Considerations

- Can be tricky if the right fittings aren’t used

- Different expansion rates between the materials

- Potential for galvanic corrosion if not properly installed

Maintenance and Care for Copper and PPR Pipe Connections

To maintain the integrity of your copper and PPR pipe connections:

- Conduct regular inspections for leaks or signs of wear.

- Keep connections clean and free of debris.

- Address leaks or pressure drops immediately by replacing fittings or re-tightening connections.

Conclusion

Connecting copper and PPR pipes is a practical solution in modern plumbing systems, offering a blend of durability, affordability, and versatility. With the right tools and techniques, you can create secure, long-lasting connections that prevent leaks and ensure smooth water flow.

FAQs

- Why would I need to connect copper and PPR pipes?

Copper and PPR pipes may be connected in systems that require the durability of copper along with the flexibility and cost-efficiency of PPR. - Can I use any type of fitting for a copper and PPR pipe connection?

No, it’s crucial to use transition fittings or compression fittings that are designed for connecting these materials. - How do I prevent leaks when connecting copper and PPR pipes?

Ensure that all connections are tightly secured, the pipes are clean and dry, and the right fittings are used. - What tools do I need to connect copper and PPR pipes?

You’ll need a pipe cutter, wrenches, transition fittings, and sealants. - Can copper and PPR pipes be used interchangeably in a plumbing system?

While both materials are compatible in some instances, connecting them requires special fittings designed for both materials to ensure a secure and leak-free connection.