Introduction

AmeriTex Pipe & Products, a prominent concrete pipe manufacturer, is making a significant strategic move in the pipe industry by launching the production of HDPE (High-Density Polyethylene) and PP (Polypropylene) pipes. This decision marks a notable shift away from traditional concrete pipes, which have long been the company’s core business.

This article will explore why AmeriTex is pivoting to HDPE and PP pipes, what advantages these materials offer over traditional concrete, and how this move aligns with the growing trends in the construction and infrastructure industries. We will also discuss the broader implications of this shift for the pipe industry as a whole.

Understanding HDPE and PP Pipes

Before diving into AmeriTex’s move, it’s important to understand what HDPE and PP pipes are and why they have gained significant traction in various industries.

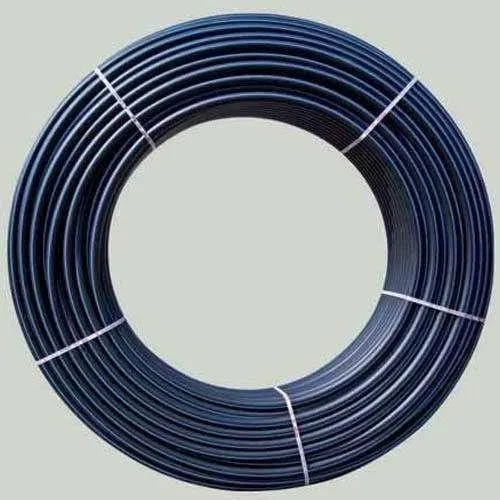

1. HDPE Pipes: A Durable and Flexible Solution

HDPE is a thermoplastic polymer made from petroleum-based monomers. It’s a popular material for pipes due to its exceptional durability, chemical resistance, and flexibility. HDPE pipes are used extensively for water distribution, sewage systems, gas distribution, and irrigation. The material is favored for its ability to withstand harsh environmental conditions, including temperature fluctuations, chemicals, and UV degradation.

Advantages of HDPE pipes include:

- Corrosion resistance: Unlike metal pipes, HDPE is not prone to rust or corrosion, which significantly extends the lifespan of the pipes.

- Flexibility: HDPE pipes can be bent and curved, which allows for easier installation in areas with limited space.

- Lightweight: HDPE pipes are much lighter than concrete, making them easier to handle, transport, and install.

- Long lifespan: HDPE pipes can last for decades with minimal maintenance, offering a cost-effective long-term solution for infrastructure.

2. PP Pipes: A Versatile and Cost-Effective Alternative

PP (Polypropylene) is another type of thermoplastic polymer that is gaining popularity in pipe manufacturing. HDPE pipes are known for their high strength-to-weight ratio, resistance to high temperatures, and chemical resistance.

Advantages of PP pipes include:

- Heat resistance: PP pipes are suitable for hot water systems because of their high heat resistance, making them ideal for industrial processes and plumbing applications.

- Chemical resistance: PP pipes are resistant to a broad range of chemicals, including acids and alkalis, making them ideal for industrial and chemical plant applications.

- Lightweight: Like HDPE, PP pipes are lighter than traditional concrete or metal pipes, reducing transportation costs and simplifying installation.

- Low thermal conductivity: This makes PP an excellent choice for hot and cold water systems, as it helps maintain temperature control.

AmeriTex’s Strategic Shift: Moving into HDPE and PP Pipe Production

AmeriTex’s decision to diversify its offerings by introducing HDPE and PP pipe production reflects several key industry trends.

1. Meeting the Growing Demand for Sustainable Solutions

As the global focus on sustainability intensifies, industries are increasingly looking for environmentally friendly solutions. HDPE and PP pipes are gaining popularity because they are highly durable, lightweight, and recyclable.

Moreover, HDPE pipes are 100% recyclable, contributing to the circular economy. AmeriTex’s move into HDPE and PP pipe production reflects a strategic alignment with these global sustainability trends.

2. Cost-Effectiveness and Efficiency in Infrastructure Projects

One of the key reasons HDPE and PP pipes have become so widely adopted is their cost-effectiveness compared to traditional materials like concrete.

On the other hand, HDPE and PP pipes are lighter, easier to install, and more resistant to environmental factors, which can translate to lower long-term costs. This further reduces installation costs and disruption to surrounding areas, making them attractive choices for modern infrastructure projects.

3. Expansion of Product Offerings to Meet Diverse Industry Needs

By adding HDPE and PP pipes to its portfolio, AmeriTex is positioning itself as a more versatile supplier for a wider range of applications.

This diversification allows AmeriTex to capture more market share in sectors that were previously outside of its core offering. The ability to offer both concrete and plastic pipes enables the company to provide tailored solutions for various customers, from municipal projects to private contractors.

The Benefits of HDPE and PP Pipes Over Concrete

AmeriTex’s expansion into HDPE and PP pipe production is a strategic response to the growing demand for alternative materials. While concrete pipes have been a reliable solution for decades, PP pipes offer several advantages that make them increasingly appealing for modern infrastructure projects.

1. Lower Weight and Easier Installation

PP pipes are significantly lighter than concrete pipes, which reduces the labor and equipment required for installation. The reduced weight also makes transportation easier, leading to cost savings throughout the supply chain.

2. Corrosion Resistance

Unlike concrete, which is prone to degradation over time due to exposure to moisture and chemicals, PP pipes are resistant to corrosion and chemical attack. This means they offer a longer service life, reducing the need for frequent repairs or replacements.

3. Flexibility and Durability

Both HDPE and PP pipes offer greater flexibility than concrete pipes, making them better suited for areas with shifting soil or extreme weather conditions.

4. Recyclability and Sustainability

Both HDPE and PP are recyclable materials, which makes them more environmentally friendly than concrete. With growing pressure to reduce waste and promote circular economies, the recyclability of HDPE and PP offers significant advantages in terms of sustainability.

AmeriTex’s Commitment to Innovation

AmeriTex’s decision to venture into PP pipe production reflects the company’s commitment to staying at the forefront of the pipe manufacturing industry. The company is also likely to continue researching new methods of improving the performance, sustainability, and cost-effectiveness of its products.

Conclusion

AmeriTex’s move to expand into PP pipe production is a strategic response to the evolving demands of the infrastructure and construction sectors. With the advantages of PP pipes, including their durability, flexibility, cost-effectiveness, and sustainability, the company is poised to capture a significant share of the growing market for plastic pipes.

Frequently Asked Questions (FAQ)

1. What are the main benefits of HDPE pipes over concrete pipes?

HDPE pipes are lighter, more flexible, and resistant to corrosion compared to concrete pipes.

2. Why is AmeriTex expanding into HDPE and PP pipe production?

AmeriTex is expanding into HDPE and PP pipe production to meet the growing demand for more sustainable, cost-effective, and flexible piping solutions in industries like water, gas, and sewage distribution.

3. Can HDPE and PP pipes be recycled?

Yes, both HDPE and PP pipes are recyclable, which makes them environmentally friendly compared to concrete, which has limited recyclability.

4. What industries use PP pipes?

PP pipes are used in water distribution, sewage systems, and gas pipelines, while PP pipes are commonly used in industrial applications, hot water systems, and chemical transport.

5. How does the shift to PP pipe production affect the environment?

The shift to PP pipe production is beneficial for the environment because these materials are recyclable and have a longer service life, which reduces waste and the need for frequent replacements. Additionally, PP pipes are less prone to corrosion, reducing maintenance and replacement costs.