Boilers are critical components in both residential and industrial settings, providing heating, hot water, and steam to systems that require a consistent thermal output. However, with the high pressure and temperature that boilers operate under, there are inherent risks associated with their use. One of the most important safety features built into modern boilers is the pop-off valve. This small but crucial valve plays a major role in ensuring that the boiler does not overheat or explode due to excessive pressure buildup. In this article, we’ll explore the function, operation, maintenance, and importance of the pop-off valve, as well as frequently asked questions to help you understand how to keep your boiler system running safely.

What Is a Pop-Off Valve?

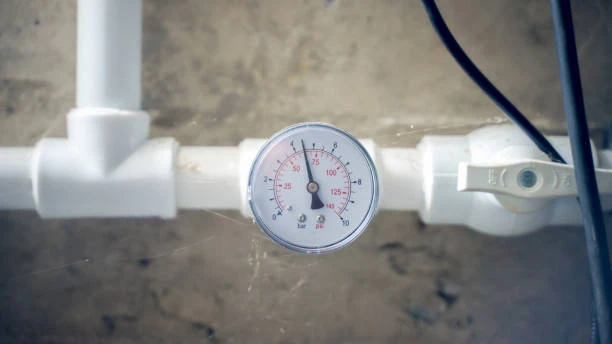

The pop-off valve, often called a safety valve or pressure relief valve, is a device designed to automatically release excess pressure in a boiler when it exceeds the system’s safe operating limit. It’s typically installed in a location where it can quickly release pressure that may build up within the system to prevent dangerous situations like boiler explosions or catastrophic failure.

Boilers work by heating water to generate steam or hot water, and this process takes place under high pressure. Without a way to manage and release this pressure, the boiler could fail catastrophically, causing significant damage to property and posing a safety risk to people in the vicinity. The pop-off valve is the first line of defense in such scenarios.

How Does a Pop-Off Valve Work?

The operation of a pop-off valve is straightforward. It is spring-loaded and designed to open when the internal pressure inside the boiler exceeds a set limit. When this occurs, the valve “pops off,” releasing steam or hot water from the system to reduce the pressure. Once the pressure drops back to a safe level, the valve automatically closes, stopping the release of steam or water.

The pop-off valve has a pressure setting that can be adjusted according to the specifications of the boiler. This setting is typically specified by the manufacturer to ensure that the boiler operates within safe pressure limits. The exact pressure limit will vary depending on the type of boiler and its intended use.

Why Is the Pop-Off Valve Important?

The importance of the pop-off valve cannot be overstated. Without it, a boiler would have no way to regulate pressure, which could result in dangerous outcomes. For example, if a boiler reaches excessive pressure, it can result in an explosion, release of scalding steam, or damage to the boiler system. The pop-off valve is critical for preventing these outcomes, making it an essential safety feature.

Here are some key reasons why the pop-off valve is crucial for boiler safety:

- Prevents Explosions: Excessive pressure can lead to a catastrophic boiler explosion. The pop-off valve ensures that the pressure remains within safe limits.

- Protects System Components: By regulating the pressure, the pop-off valve prevents damage to the boiler’s components, such as pipes, the heat exchanger, and other critical parts.

- Reduces Risk of Scalding: High-pressure steam or water can cause serious burns or injuries. The valve reduces the likelihood of such risks by safely releasing excess pressure.

- Maintains System Efficiency: Pressure that exceeds the safe limit can reduce the efficiency of the boiler, leading to increased energy consumption and costs. The pop-off valve helps maintain optimal operating conditions.

Common Issues with Pop-Off Valves

While the pop-off valve is an essential safety feature, it can experience certain problems that can affect the boiler’s overall functionality. Here are some common issues to watch for:

1. Valve Leakage

Over time, the pop-off valve may begin to leak. This can occur if the valve is damaged, corroded, or not seating properly. Leaking valves can cause a loss of pressure, which can affect the boiler’s performance and efficiency. Regular inspections should be carried out to check for any signs of leakage.

2. Sticking or Jammed Valve

The valve can become stuck or jammed due to debris or mineral buildup, especially in areas with hard water. If the valve fails to open when pressure exceeds the limit, it can lead to dangerous overpressure conditions. Regular maintenance and cleaning can help prevent this issue.

3. Improper Pressure Settings

If the pressure setting of the pop-off valve is incorrect, the valve may not open when it should. This can occur if the valve is incorrectly calibrated during installation or if there has been a malfunction of the valve’s pressure sensor. It is important to ensure that the pressure setting is aligned with the boiler’s design specifications.

4. Corrosion

Over time, corrosion can affect the valve, particularly if the boiler is exposed to harsh operating conditions or if regular maintenance is neglected. Corrosion can weaken the valve, causing it to malfunction or fail to open under pressure.

5. Valve Failure

Like all mechanical components, the pop-off valve has a finite lifespan. If the valve becomes worn out or faulty, it may fail to perform its intended function. This is why it’s essential to replace the valve at regular intervals, as recommended by the manufacturer.

How to Maintain a Pop-Off Valve

To ensure that the pop-off valve continues to function properly and effectively, it is important to maintain it regularly. Here are some key maintenance tips:

1. Regular Inspections

Perform routine inspections to check for any visible signs of wear, damage, or leaks. Pay attention to the valve’s connections, seat, and spring mechanism to ensure they are intact.

2. Test the Valve

Periodically test the valve to make sure it opens and closes properly. This can be done by manually raising the pressure in the system (using a test gauge) and observing whether the valve opens when the pressure exceeds the set limit. Always perform this test carefully and follow safety protocols.

3. Clean the Valve

Clean the valve regularly to prevent debris or mineral buildup, especially in areas with hard water. This can help prevent sticking and ensure the valve operates smoothly.

4. Replace Worn or Damaged Parts

If the pop-off valve appears to be worn, corroded, or damaged, it is essential to replace it immediately. Ignoring these signs can lead to catastrophic failure.

5. Follow Manufacturer Guidelines

Each boiler and pop-off valve has specific maintenance and safety guidelines provided by the manufacturer. Be sure to follow these recommendations to maintain the safety and efficiency of your system.

When Should You Replace a Pop-Off Valve?

It is essential to replace a pop-off valve under the following circumstances:

- If it is leaking or cannot hold pressure.

- If it does not open or close properly during tests.

- If it shows signs of significant corrosion or wear.

- If it has been in service for longer than the manufacturer’s recommended lifespan (typically 5 to 10 years).

Always consult with a licensed technician to inspect and replace the valve when necessary.

Conclusion

The pop-off valve is a critical safety feature in any boiler system, designed to release excess pressure and prevent catastrophic failures. Regular maintenance and monitoring of the valve’s performance are essential for the safe operation of the boiler. Ensuring that the pop-off valve is functioning correctly will keep your boiler running efficiently and reduce the risk of accidents, injuries, and costly repairs.

By understanding how the pop-off valve works and the role it plays in boiler safety, you can ensure your boiler system remains in top condition and operates smoothly. Always seek professional help if you notice any issues with the valve or the overall boiler system.

Frequently Asked Questions (FAQs)

1. How often should I test the pop-off valve on my boiler?

It’s recommended to test the pop-off valve at least once a year during routine maintenance to ensure it is functioning correctly.

2. Can I replace the pop-off valve myself?

Replacing a pop-off valve requires expertise, as improper installation can lead to safety issues. It’s best to hire a licensed technician to handle the replacement.

3. Why does my pop-off valve keep leaking?

A leaking pop-off valve could be due to a worn-out valve seat, corrosion, or debris buildup. It is important to inspect and clean the valve or replace it if necessary.

4. How can I prevent my pop-off valve from getting stuck?

Regular cleaning and maintenance are key to preventing a pop-off valve from becoming stuck. Ensure the valve is free of debris and mineral buildup, especially in areas with hard water.

5. What should I do if the pop-off valve doesn’t open when pressure exceeds the limit?

If the pop-off valve fails to open, this could indicate a malfunction or incorrect pressure setting. Contact a professional technician immediately to inspect and repair the valve.