Efficient and reliable waste management is crucial for environmental sustainability, and sludge treatment facilities play a central role in this process. In the UK, a leading sludge treatment plant has recently upgraded its system with fast-acting relief valves to enhance operational safety and efficiency. These specialized valves protect infrastructure, ensure smooth operations, and support the plant’s commitment to meeting environmental standards.

This article delves into the importance of relief valves in sludge treatment, their benefits, and how they address the unique challenges of this sector.

What Are Relief Valves?

Relief valves are mechanical devices designed to release excess pressure from systems such as pipelines, tanks, or reactors. They prevent overpressure scenarios that could lead to equipment damage or system failure.

In sludge treatment, where varying pressures are common due to the nature of the waste material, relief valves are essential for maintaining operational safety and efficiency.

Key Features of Fast-Acting Relief Valves

Fast-acting relief valves are a step ahead of traditional models, offering enhanced responsiveness and precision in pressure management.

1. Rapid Response Time

These valves activate immediately when pressure exceeds safe limits, minimizing the risk of damage.

2. Corrosion Resistance

Constructed with materials like stainless steel or specialized alloys, they withstand the harsh conditions typical of sludge treatment processes.

3. Self-Cleaning Mechanisms

Some models include self-cleaning features to prevent blockages caused by sludge or debris.

4. Customizable Settings

Operators can adjust pressure thresholds to suit specific applications, ensuring flexibility across various operational scenarios.

5. Durability and Longevity

Built for high-frequency use, these valves maintain performance over extended periods with minimal maintenance.

The Role of Relief Valves in Sludge Treatment Facilities

Sludge treatment involves processing wastewater byproducts to reduce volume, eliminate pathogens, and recover valuable resources. This process generates fluctuating pressures that require effective management to avoid disruptions.

Applications of Relief Valves:

- Digesters: Manage gas pressures in anaerobic digestion tanks.

- Pipelines: Prevent overpressure during sludge transport.

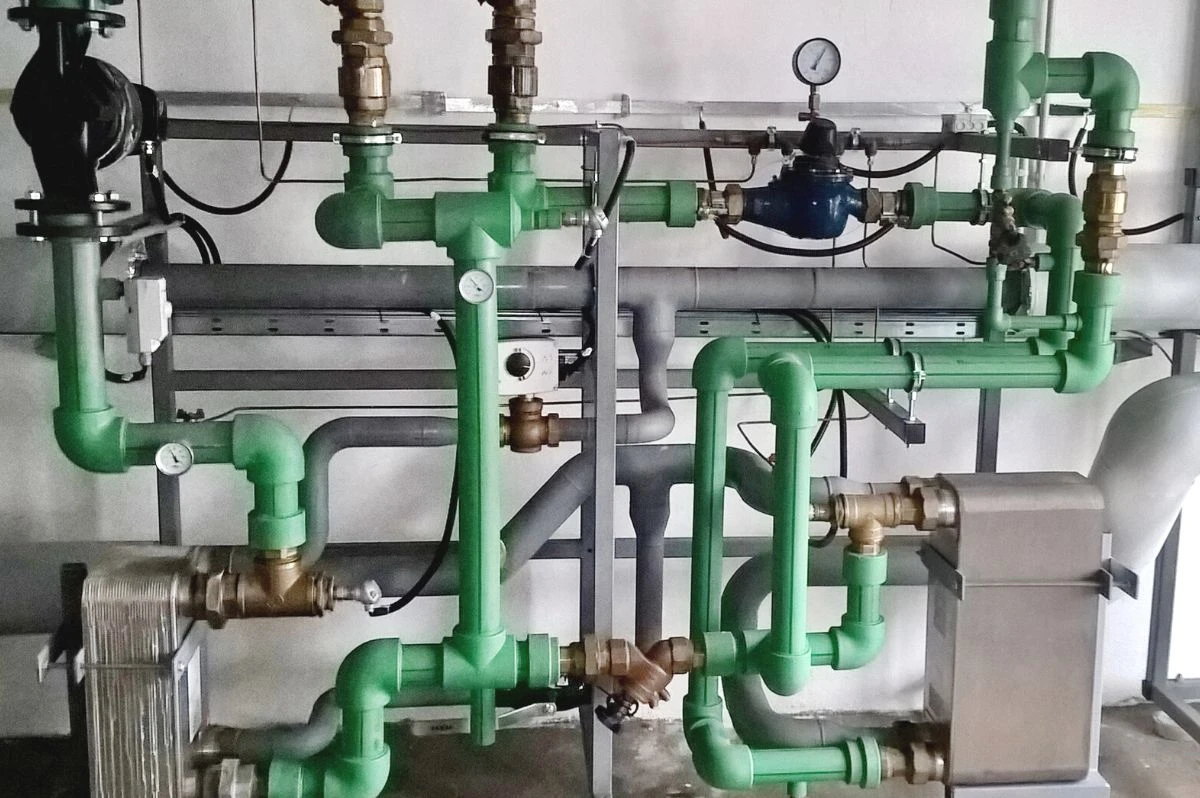

- Heat Exchangers: Protect against thermal expansion pressures.

- Storage Tanks: Ensure safety during sludge storage by releasing excess gas or liquid.

Benefits for Sludge Treatment:

- Enhanced Safety: Relief valves mitigate the risks of overpressure explosions or system failures.

- Operational Efficiency: By maintaining consistent pressures, they optimize the performance of equipment.

- Reduced Downtime: Fast-acting valves quickly address pressure anomalies, minimizing disruptions.

How the UK Facility Upgraded with Relief Valves

The UK sludge treatment facility faced challenges with frequent pressure surges during its operations. These surges posed risks to equipment and reduced system efficiency.

The Upgrade Process:

- Assessment of Needs

Engineers conducted a thorough assessment to identify high-risk points in the system where pressure surges occurred. - Selection of Relief Valves

Based on their requirements, the facility opted for fast-acting relief valves featuring corrosion-resistant materials and self-cleaning capabilities. - Installation and Testing

The valves were installed at critical points, including digesters, pipelines, and heat exchangers. Rigorous testing ensured their performance met safety and operational standards. - Integration with Monitoring Systems

The valves were integrated into the facility’s monitoring system, allowing real-time tracking and automated alerts for pressure anomalies.

Results of the Upgrade

Since implementing the relief valves, the UK sludge treatment facility has experienced notable improvements:

1. Improved Safety

The fast-acting valves have successfully prevented overpressure incidents, safeguarding equipment and personnel.

2. Enhanced Efficiency

Consistent pressure management has optimized sludge processing, reducing energy consumption and operational costs.

3. Increased Reliability

The valves’ robust design has minimized maintenance needs, ensuring uninterrupted operations.

4. Compliance with Regulations

The facility now meets stricter environmental and safety standards, reinforcing its commitment to sustainability.

The Future of Relief Valves in Waste Management

As sludge treatment and other waste management sectors evolve, the demand for advanced relief valve will continue to grow. Innovations in materials, design, and automation are shaping the next generation of these essential components.

Emerging Trends:

- Smart Valves: Integration with IoT for predictive maintenance and real-time adjustments.

- Eco-Friendly Designs: Use of sustainable materials to align with environmental goals.

- Enhanced Durability: Development of valves with longer lifespans to reduce waste.

Relief valve will remain a cornerstone of safe and efficient operations in sludge treatment and beyond.

Conclusion

The adoption of fast-acting relief valve at the UK sludge treatment facility demonstrates the critical role of advanced pressure management systems in modern waste management. These valves not only enhance safety and efficiency but also support the facility’s broader goals of sustainability and regulatory compliance.

As the industry continues to innovate, relief valve will play an increasingly vital role in optimizing processes, protecting equipment, and ensuring environmental stewardship.

FAQs About Relief Valves

1. What is the primary purpose of relief valve in sludge treatment?

Relief valve release excess pressure in systems to prevent equipment damage and ensure safe operations.

2. How do fast-acting relief valve differ from traditional ones?

Fast-acting relief valve respond more quickly to pressure surges, offering better protection for high-risk systems.

3. Are relief valve suitable for corrosive environments?

Yes, many relief valve are made with corrosion-resistant materials to handle harsh conditions, such as those found in sludge treatment.

4. How often should relief valve be maintained?

Regular inspections are recommended, but modern relief valve often require minimal maintenance thanks to durable materials and self-cleaning features.

5. Can relief valve be automated?

Yes, many modern relief valve can integrate with automated monitoring systems for real-time adjustments and alerts.