Introduction: Soleno Expands with First U.S. HDPE Pipe Plant

Soleno, a leading Quebec-based HDPE pipe maker, has just opened its first manufacturing plant in the United States. This strategic expansion represents a significant milestone for the company, allowing it to serve the growing demand for high-density polyethylene (HDPE) pipes in the U.S. The move reflects Soleno’s commitment to innovation and regional growth, making it a key player in the North American HDPE pipe market.

Why HDPE Pipes Are in High Demand

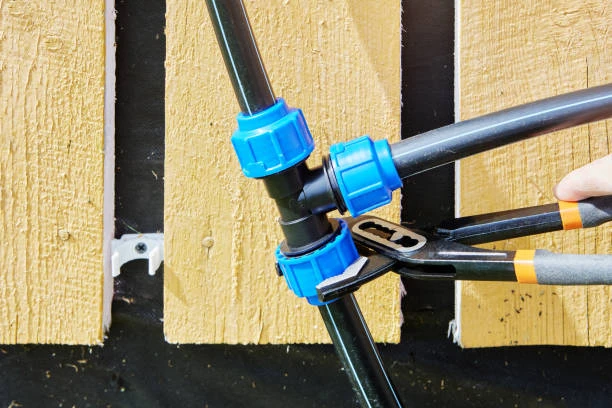

HDPE pipes are highly sought after for their durability, corrosion resistance, and low maintenance costs. HDPE pipe makers like Soleno produce these pipes for a variety of applications, including water distribution, wastewater systems, and stormwater management. High-density polyethylene offer several advantages over traditional materials, including their lightweight nature, flexibility, and long lifespan. The growing demand for sustainable, reliable infrastructure solutions is driving the expansion of HDPE pipe manufacturing.

Soleno’s Strategic Move into the U.S. Market

Opening a plant in the U.S. marks an important step in Soleno’s strategy to increase its market share in North America. The company’s decision to establish a U.S. facility is driven by several factors, including proximity to key markets, a stronger supply chain, and reduced shipping costs. By having a local presence, Soleno can better serve U.S. customers, reduce lead times, and improve its competitive edge in the market.

The Role of the U.S. Plant in Soleno’s Growth

The new U.S. plant will play a crucial role in Soleno’s expansion strategy. As a HDPE pipe maker, the company can now meet the increasing demand for HDPE pipes more efficiently. The plant will manufacture a wide range of HDPE products tailored to meet U.S. market requirements. With its advanced manufacturing technologies and strategic location, the new plant positions Soleno to become a key player in the U.S. infrastructure sector.

The Benefits of Local Manufacturing for U.S. Customers

For U.S. customers, Soleno’s new HDPE pipe maker plant provides several benefits. Local manufacturing ensures faster delivery times, reducing the lead time for projects that require HDPE pipes. Additionally, the U.S. plant enables Soleno to offer more competitive pricing due to lower transportation costs. The ability to produce HDPE pipes closer to U.S. customers will help meet the growing demand for reliable infrastructure solutions in both urban and rural areas.

Quality and Innovation at Soleno’s U.S. Plant

Soleno’s U.S. plant will feature state-of-the-art manufacturing technologies to produce high-quality HDPE pipes. As an HDPE pipe maker, Soleno has long been committed to using advanced extrusion techniques to ensure the durability and performance of its products. The plant will also focus on innovation, continuously improving the efficiency and sustainability of its manufacturing processes. This commitment to quality will ensure that Soleno remains a trusted name in the HDPE pipe industry.

Sustainability and Environmental Impact

One of the key benefits of HDPE pipes is their environmental sustainability. HDPE pipe makers like Soleno use recyclable materials, which helps reduce plastic waste and promote a circular economy. The new U.S. plant will support Soleno’s efforts to provide sustainable solutions by producing eco-friendly HDPE pipes that are energy-efficient and long-lasting. These pipes contribute to environmental conservation by reducing the need for frequent repairs or replacements, which are common with traditional materials like concrete or metal.

The Growing Infrastructure Demand in the U.S.

The U.S. faces increasing pressure to upgrade and maintain its infrastructure, especially in water management systems. HDPE pipe makers are essential in meeting this demand for modern infrastructure solutions. Soleno’s U.S. plant will help support projects focused on improving water distribution, sewage systems, and stormwater management. The plant’s strategic location will allow Soleno to meet the needs of both public and private sector projects, offering reliable HDPE pipes for a wide range of applications.

How Soleno’s U.S. Plant Supports the U.S. Economy

Soleno’s new U.S. HDPE pipe maker plant will also provide economic benefits to the local community. The facility will create numerous jobs in manufacturing, engineering, and logistics, supporting the local economy. Additionally, by sourcing materials locally, Soleno can reduce its environmental footprint while supporting U.S. suppliers. This move aligns with Soleno’s commitment to sustainable practices and its role in fostering economic growth in North America.

The Competitive Advantage of Soleno’s U.S. Plant

Having a U.S.-based manufacturing facility gives Soleno a competitive advantage in the North American HDPE pipe market. It allows the company to respond more quickly to customer demands and provide tailored solutions for specific regional needs. Local production gives Soleno an edge over competitors, reducing costs and improving supply chain efficiency.

Soleno’s Commitment to Customer Satisfaction

Soleno has long been recognized as a customer-focused HDPE pipe maker, and this new plant is a reflection of that commitment. By investing in local manufacturing in the U.S., Soleno can offer faster response times, improved customer service, and a greater ability to meet specific project requirements. The company will continue to prioritize customer satisfaction by providing high-quality HDPE pipes and ensuring timely delivery for a variety of infrastructure projects.

The Future of HDPE Pipe Manufacturing in the U.S.

The opening of Soleno’s U.S. plant signals a positive future for HDPE pipe makers in North America. As the demand for sustainable, durable infrastructure solutions grows, HDPE pipes will play an increasingly important role in the construction and utilities sectors. The U.S. market is expected to continue expanding, driven by both the need for new infrastructure and the desire to replace outdated systems. Soleno is well-positioned to lead this transformation by providing high-quality, cost-effective HDPE pipes that meet the evolving needs of the industry.

Conclusion: A Strategic Move for Soleno and the U.S. Market

Soleno’s decision to open its first U.S. HDPE pipe maker plant is a significant step toward meeting the growing demand for sustainable, reliable infrastructure solutions. The new facility will enhance Soleno’s ability to serve U.S. customers, reduce delivery times, and offer more competitive pricing. As the company continues to innovate and expand, it is well-positioned to become a key player in the North American HDPE pipe market.

Frequently Asked Questions (FAQs)

1. Why did Soleno open a U.S. plant?

Soleno opened the U.S. plant to meet growing HDPE pipe demand, reduce shipping costs, and improve delivery times.

2. What are HDPE pipes?

HDPE pipes are made from high-density polyethylene, known for their durability, resistance to corrosion, and suitability for water, sewage, and stormwater systems.

3. How will the U.S. plant benefit U.S. customers?

The U.S. plant enables Soleno to offer faster delivery, competitive pricing, and locally-produced HDPE pipes for infrastructure needs.

4. How does HDPE compare to other pipe materials?

HDPE pipes are lightweight, durable, and corrosion-resistant, making them superior to traditional materials like concrete, steel, or PVC in many applications.

5. What is Soleno’s commitment to sustainability?

Soleno produces eco-friendly HDPE pipes using recyclable materials and energy-efficient processes at its new U.S. plant.