Introduction

PVC water fittings are crucial in modern plumbing and water management systems. Their importance increases significantly in thermal wells, where they endure high temperatures, pressure, and chemical exposure. Maintaining the integrity of these fittings is essential for ensuring reliability and long-term performance. This article delves into the integrity assessment of high-performance PVC water fittings for thermal wells, offering insights into their features, benefits, and testing methodologies.

Understanding PVC Water Fitting

What Are PVC Water Fitting?

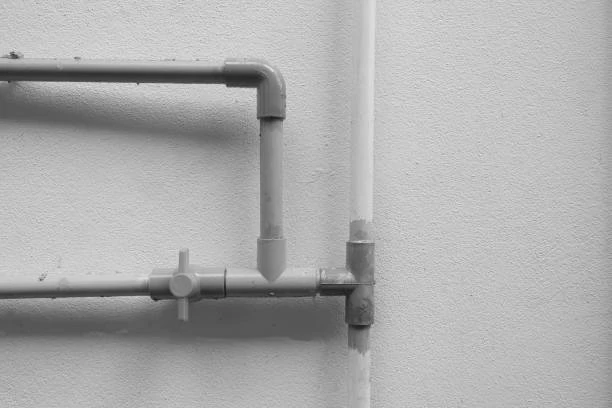

PVC (Polyvinyl Chloride) water fittings are connectors used to join pipes in water systems. These fittings are known for their exceptional durability, resistance to corrosion, and cost-effectiveness.

Key Features of PVC Water Fitting

PVC fittings excel in durability, chemical resistance, and lightweight construction, making them ideal for high-stress applications like thermal wells. Their non-reactive nature ensures they withstand extreme conditions without degrading.

Applications in Thermal Wells

Thermal wells involve extracting or managing water from deep underground. PVC water fitting in these setups must handle thermal stress, high pressure, and chemical exposure while maintaining structural integrity.

Importance of Integrity in Thermal Well Fittings

Thermal Stress and PVC Performance

Thermal wells expose fittings to varying temperatures. High-performance PVC fittings resist deformation and expansion, ensuring a secure connection under stress.

Resistance to Corrosion and Chemicals

Unlike metal fittings, PVC resists rust and chemical reactions, making it a safer choice for transporting water in chemically active environments.

Ensuring Longevity in High-Pressure Systems

Maintaining the integrity of PVC fittings helps prevent leaks and failures, ensuring uninterrupted service in high-pressure applications.

Factors Affecting the Integrity of PVC Water Fitting

Material Quality

The quality of PVC used directly impacts the fitting’s ability to withstand thermal and mechanical stress. High-grade materials ensure better performance.

Installation Techniques

Proper installation minimizes stress on fittings. Incorrect methods can compromise their integrity, leading to leaks or system failures.

Maintenance Practices

Regular inspections and maintenance prolong the lifespan of PVC fittings, ensuring consistent performance.

Testing and Assessment Techniques

Pressure Testing

This involves subjecting the fittings to pressures beyond normal operating conditions to ensure they can handle extreme situations.

Thermal Expansion Analysis

Testing for thermal expansion ensures that the fittings maintain integrity under fluctuating temperatures.

Chemical Resistance Evaluation

Exposure to chemicals helps evaluate how well the PVC fittings resist degradation in chemically active environments.

Advantages of High-Performance PVC Water Fitting for Thermal Wells

Cost-Effectiveness

PVC fittings are affordable compared to metal alternatives while offering similar or superior performance.

Easy Installation

Lightweight and easy-to-handle PVC fittings reduce installation time and costs.

Environmentally Friendly

Recyclable PVC contributes to sustainability efforts in modern construction and plumbing systems.

Real-World Applications and Case Studies

Successful Implementation in Thermal Wells

PVC water fittings have been used successfully in various thermal well projects worldwide, demonstrating their reliability and effectiveness.

Lessons Learned from Failures

Instances of failures highlight the importance of choosing high-quality materials and proper installation techniques.

Future of PVC Water Fitting in Thermal Wells

Innovations in Material Science

Advancements in PVC formulations aim to enhance durability and thermal resistance, making these fittings even more reliable.

Enhancing Durability and Performance

Future developments focus on creating fittings that outperform current standards, setting new benchmarks in the industry.

Conclusion

Integrity assessments of PVC water fitting are critical for ensuring the safety and reliability of thermal well systems. These fittings offer a blend of durability, affordability, and sustainability, making them an indispensable choice in modern water management. With continuous advancements, PVC water fitting are set to become even more efficient, catering to the demanding requirements of thermal wells.

FAQs

1. What makes PVC water fittings suitable for thermal wells?

Their durability, chemical resistance, and ability to withstand high temperatures make PVC fittings ideal for thermal well applications.

2. How is the integrity of PVC water fittings tested?

Testing includes pressure tests, thermal expansion analysis, and chemical resistance evaluations.

3. What are the common challenges in using PVC water fittings for thermal wells?

Challenges include material quality variations, improper installation, and maintenance lapses.

4. Are there eco-friendly options in PVC water fittings?

Yes, many PVC water fittings are recyclable, aligning with sustainability goals.

5. How do PVC water fittings compare to alternatives?

PVC fittings are more affordable, lightweight, and corrosion-resistant than metal counterparts, offering excellent value for thermal well applications.