Stormwater management is a critical component of modern infrastructure. With increasing urbanization and unpredictable weather patterns, cities around the world are facing greater challenges in managing stormwater runoff. PPS stormwater pipe systems have emerged as a key solution to these problems. However, while these systems have seen considerable success, they also come with their own set of challenges. This article will explore the successes and challenges of PPS stormwater pipes, highlighting real-world stories and providing insights into their role in effective stormwater management.

What is a PPS Stormwater Pipe?

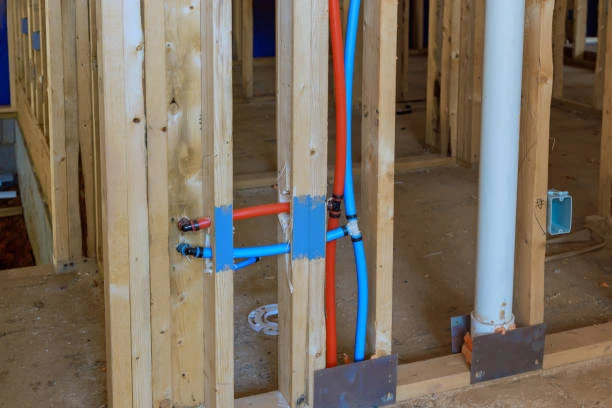

PPS stormwater pipe refers to a type of pipe used for transporting rainwater or stormwater runoff to drainage systems. Manufacturers typically make these pipes from durable materials like PVC, polyethylene, or polypropylene, designed to withstand high pressure and harsh weather conditions. Developers widely use PPS stormwater pipes in residential, commercial, and large-scale municipal infrastructure projects.

Key Features of PPS Stormwater Pipes

- Durability: PPS stormwater pipes are designed to endure the wear and tear caused by high-pressure water flow and harsh environmental factors.

- Corrosion Resistance: Unlike traditional metal pipes, PPS stormwater pipes are resistant to rust and corrosion, ensuring a longer lifespan.

- Ease of Installation: These pipes are lightweight, which makes them easier to handle and install compared to other piping materials.

Stories of Success in Using PPS Stormwater Pipes

Around the world, cities and municipalities have seen success in using PPS stormwater pipes for managing stormwater runoff and preventing flooding. These pipes offer several advantages, including efficiency, durability, and cost-effectiveness. Here are some notable success stories that highlight the role of PPS stormwater pipes in modern stormwater management.

Case Study 1: Urban Drainage in Australia

In Australia, where unpredictable rainfall and flash flooding are common, PPS stormwater pipes have played a key role in upgrading urban drainage systems. The city of Brisbane, for example, faced frequent flooding due to an outdated drainage system. By replacing old concrete pipes with PPS stormwater pipes, the city was able to significantly improve its stormwater management. The new pipes provided better flow capacity and were more resistant to wear and tear caused by harsh weather conditions.

The use of PPS stormwater pipes also reduced maintenance costs, as the material is much more durable than the old concrete infrastructure. The installation process was faster and less disruptive to the city’s traffic flow. As a result, Brisbane has seen fewer flooding incidents, even during heavy rainfall events, making the city safer for its residents.

Case Study 2: Flood Mitigation in California

In California, seasonal storms can overwhelm drainage systems, so engineers used PPS stormwater pipes in a flood mitigation project in Los Angeles. Decades ago, the city built its stormwater infrastructure, but it can no longer handle the growing runoff volume due to increased urbanization and more intense rainstorms. The city decided to replace its aging infrastructure with PPS stormwater pipes, which offered better flow rates and were more resilient to environmental stress.

The success of the project was evident in the reduction of flooding during the rainy season. By replacing old stormwater pipes with modern PPS stormwater pipes, Los Angeles significantly reduced water damage to properties and minimized disruptions to daily life. The new pipes also helped improve water quality, as they reduced the chances of stormwater contamination in the city’s waterways.

Case Study 3: Stormwater Management in New York

New York City is known for its large, complex stormwater management system. However, despite having one of the most advanced drainage systems in the world, the city still faces challenges when it comes to managing runoff during heavy rainstorms. In recent years, the city has adopted PPS stormwater pipes for several infrastructure upgrades. These pipes have been used to replace outdated sections of the city’s sewer system, especially in areas prone to flooding.

One of the key benefits of PPS stormwater pipes in New York has been their ability to withstand freezing temperatures during the winter months. This has been particularly important in preventing blockages and pipe damage caused by ice buildup. Additionally, the new pipes have allowed for faster and more efficient water flow, reducing the risk of sewer backups and flooding.

Challenges of Using PPS Stormwater Pipes

While PPS stormwater pipes have proven to be a reliable solution in many areas, they do come with their own set of challenges. These challenges are often related to installation, cost, and maintenance, and they vary depending on the project’s scope and location.

Challenge 1: Installation in Difficult Terrain

One of the main challenges faced by municipalities when using PPS stormwater pipes is installation in difficult or uneven terrain. In areas with steep slopes or challenging soil conditions, installing these pipes can be time-consuming and costly. Proper alignment and support are necessary to prevent the pipes from shifting, which can cause blockages or failures over time.

To address this challenge, engineers must carefully plan the installation process and install the pipes at the correct depth and angle. This requires expert knowledge of local soil conditions and may involve additional equipment and labor costs.

Challenge 2: Higher Initial Costs

Although PPS stormwater pipes can save municipalities money in the long term due to their durability and low maintenance needs, the initial costs of purchasing and installing the pipes can be higher than traditional piping systems. For many smaller municipalities or projects with limited budgets, this can pose a significant barrier to adoption.

To overcome this challenge, it’s important for local governments and project managers to carefully evaluate the long-term cost savings associated with PPS stormwater pipes. The pipes reduce the need for maintenance, require fewer repairs, and have a longer lifespan, making them a more cost-effective option over time.

Challenge 3: Environmental Concerns

Although manufacturers make PPS stormwater pipes from synthetic materials like PVC and polyethylene, they remain highly durable and resistant to corrosion. The materials are not biodegradable, and concerns have arisen about their environmental impact at the end of the pipes’ lifecycle. Recycling these pipes can be challenging, and improper disposal can lead to environmental pollution.

However, advancements in recycling technologies and sustainable manufacturing processes are helping address these concerns. Some manufacturers are now focusing on producing more environmentally friendly versions of PPS stormwater pipes, incorporating recycled materials and improving recyclability.

Future Trends in Stormwater Management and PPS Stormwater Pipes

As cities continue to grow and face the challenges of climate change, the role of PPS stormwater pipes in stormwater management will only become more important. The need for effective, sustainable infrastructure will drive innovation in piping systems and encourage the use of new technologies.

Smart Stormwater Solutions

One of the key future trends in stormwater management is the integration of smart technologies into piping systems. The use of sensors, real-time monitoring, and data analytics can help cities better manage stormwater runoff and prevent flooding. Cities can equip PPS stormwater pipes with smart technologies, providing valuable insights into water flow, pipe conditions, and maintenance needs.

Sustainable Materials

In response to growing environmental concerns, manufacturers are increasingly focusing on creating sustainable PPS stormwater pipe. These new pipes may be made from recycled plastics, biodegradable materials, or have a reduced carbon footprint. As sustainability becomes a priority, PPS stormwater pipes will evolve to meet these demands and make stormwater management more environmentally responsible.

Conclusion

Many cities around the world have found PPS stormwater pipes to be an effective and reliable solution for stormwater management. Despite challenges like installation complexity and cost, municipalities choose these pipes for their durability, corrosion resistance, and ability to handle heavy water flow. As cities adapt to climate change and urbanization, PPS stormwater pipes will help ensure efficient, sustainable stormwater management.

Frequently Asked Questions (FAQs)

- What are PPS stormwater pipes made from? Manufacturers typically make PPS stormwater pipes from durable materials like PVC, polyethylene, or polypropylene, designed to withstand harsh environmental conditions.

- What are the main advantages of using PPS stormwater pipes? PPS stormwater pipes are durable, corrosion-resistant, lightweight, and easy to install. They also provide better flow capacity and require less maintenance than traditional pipes.

- Are there any environmental concerns with PPS stormwater pipes? Yes, PPS stormwater pipes are made from synthetic materials, which are not biodegradable. However, advances in recycling and sustainability are helping mitigate these concerns.

- How do PPS stormwater pipes perform in cold climates? PPS stormwater pipes are resistant to freezing and cracking, making them suitable for use in cold climates where traditional pipes may struggle.

- Can PPS stormwater pipes be used in challenging terrains? Yes, installing pipes in difficult terrains, such as steep slopes or rocky areas, requires special equipment and additional planning to ensure proper alignment.