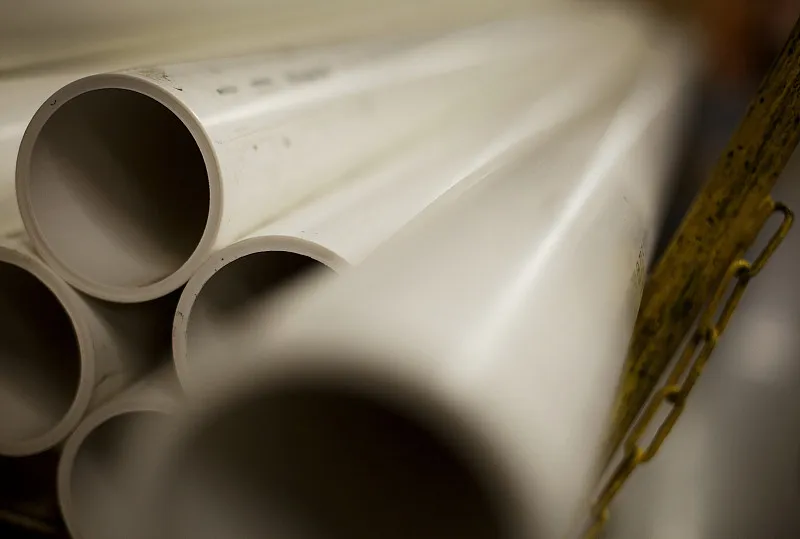

Introduction PPR Pipe

PPR Pipe, also known as Polypropylene Random Copolymer pipes, have revolutionized plumbing and piping systems across various industries. These pipes are known for their exceptional durability, resistance to temperature variations, and non-corrosive properties, making them suitable for multiple applications. From residential plumbing to industrial systems, the versatility of PPR pipes has made them an essential component of modern infrastructure.

In this article, we will explore the different areas where PPR pipes are used, their benefits, and why they are the preferred choice for various applications.

What is a PPR Pipe?

PPR pipes are made from polypropylene random copolymer, a type of plastic that offers excellent strength and thermal resistance. These pipes can handle both hot and cold water and are resistant to chemicals, making them suitable for diverse applications.

PPR pipes are joined using a fusion welding process, creating leak-proof joints that ensure long-term reliability. Their lightweight nature, combined with a long lifespan of over 50 years, makes them a cost-effective and durable choice for modern piping systems.

Key Benefits of PPR Pipe

- Durability

PPR pipes are highly durable and resistant to wear and tear, ensuring long-term performance even under extreme conditions. - Temperature Resistance

These pipes can handle temperatures ranging from -20°C to 95°C, making them ideal for both hot and cold water systems. - Corrosion Resistance

Unlike metal pipes, PPR pipes do not corrode or rust, ensuring clean and safe water delivery. - Non-Toxic and Safe

PPR pipes are made from non-toxic materials, making them safe for transporting potable water and other fluids. - Leak-Proof Joints

The fusion welding process ensures strong, seamless, and leak-proof connections. - Lightweight and Easy to Install

PPR pipes are lightweight, reducing transportation and installation costs while making the process easier. - Eco-Friendly and Recyclable

PPR pipes are 100% recyclable, making them an environmentally friendly option.

Where are PPR Pipe Used?

1. Residential Plumbing Systems

PPR pipes are extensively used in residential buildings for supplying both hot and cold water. Their temperature resistance and non-corrosive nature make them ideal for home water supply systems, including kitchens, bathrooms, and laundry systems.

- Hot water distribution systems

- Cold water pipelines

- Under-sink plumbing

- Heating systems in homes

PPR pipes ensure clean and safe water delivery without any contamination, providing homeowners with a reliable and long-lasting plumbing solution.

2. Commercial Plumbing Systems

In commercial settings like office buildings, hotels, and shopping malls, PPR pipes are used to deliver water efficiently and safely. Their ability to handle high pressure and temperature variations makes them suitable for large-scale plumbing systems.

- Water supply systems in multi-story buildings

- Centralized hot water systems in hotels and hospitals

- Water pipelines for office spaces

- Air-conditioning and cooling systems

Commercial establishments benefit from PPR pipes due to their low maintenance and leak-proof performance, reducing long-term costs.

3. Industrial Applications

PPR pipes are widely used in industries for transporting fluids, chemicals, and gases. Their chemical resistance and durability allow them to perform reliably in harsh industrial environments.

- Chemical transport pipelines

- Cooling and heating systems in factories

- Pressurized water systems

- Compressed air transportation

Industries that require piping systems resistant to corrosion, high pressure, and temperature fluctuations prefer PPR pipes for their efficiency and long lifespan.

4. Agriculture and Irrigation

PPR pipes are use in agriculture and irrigation systems to distribute water efficiently. Their durability and resistance to environmental stress make them ideal for outdoor applications.

- Irrigation systems for farms and greenhouses

- Water supply for livestock farming

- Fertilizer and chemical transport pipelines

PPR pipes ensure steady water flow in agricultural systems, helping farmers maintain efficient irrigation with minimal water loss.

5. Heating Systems

PPR pipes are an excellent choice for heating systems due to their thermal resistance and ability to withstand high temperatures. They are widely use in both residential and commercial heating applications.

- Underfloor heating systems

- Radiator connections

- Centralized heating systems

- Hot water supply lines

The ability of PPR pipes to maintain efficiency under high temperatures makes them a preferred option for heating systems.

6. Healthcare and Food Industries

PPR pipes are non-toxic and safe for transporting potable water, making them suitable for the healthcare and food industries. These industries require pipes that do not contaminate water or fluids.

- Water supply systems in hospitals and clinics

- Food processing plants for clean water distribution

- Sterile water transport for laboratories

PPR pipes ensure the purity and safety of the water being transport, meeting the strict hygiene standards of these industries.

7. Water Treatment Plants

PPR pipes are use in water treatment plants to transport treated water safely and efficiently. Their resistance to corrosion and chemicals makes them an ideal choice for such applications.

- Transporting treated potable water

- Chemical dosing pipelines

- Wastewater treatment systems

PPR pipes help maintain the quality of treated water without adding any contaminants, ensuring safe water distribution.

8. Swimming Pools and Recreational Facilities

PPR pipes are widely use in swimming pools for water circulation and filtration systems. Their resistance to chlorine and chemicals makes them a durable choice for such applications.

- Water circulation systems

- Pool heating pipelines

- Filtration systems

PPR pipes ensure leak-proof and efficient performance in swimming pool installations, reducing maintenance costs.

Why PPR Pipe are Preferred Across Applications

- High resistance to pressure, temperature, and chemicals

- Leak-proof and seamless joints for long-term reliability

- Lightweight and easy to install, reducing labor costs

- Non-toxic material ensures safety for potable water applications

- Long lifespan exceeding 50 years with minimal maintenance

PPR pipes are versatile and efficient, offering solutions for a wide range of applications across residential, commercial, industrial, and agricultural sectors.

Tips for Installing PPR Pipe

- Use a proper pipe cutter to make clean and straight cuts.

- Chamfer the edges after cutting to ensure smooth fusion welding.

- Follow the recommended heating time and temperature for fusion welding.

- Use supporting clamps and brackets to secure pipes in place.

- Perform a pressure test after installation to check for leaks.

Proper installation ensures the longevity and efficiency of PPR pipes in any application.

Conclusion

PPR pipes are a versatile, durable, and eco-friendly solution for modern plumbing systems. From residential water supply systems to industrial chemical transportation and agricultural irrigation, PPR pipes have proven their reliability and efficiency. Their ability to withstand high pressure, temperature fluctuations, and corrosion makes them the preferred choice across multiple industries.

With proper installation and maintenance, PPR pipes offer long-term performance, ensuring safe and clean water distribution in all types of applications. Whether for homes, industries, or agricultural fields, PPR pipes continue to be the go-to solution for robust and leak-proof piping systems.

Frequently Asked Questions (FAQs)

- Where are PPR pipes commonly used?

PPR pipes are use in residential plumbing, commercial water systems, industrial applications, heating systems, agriculture, and swimming pool installations. - Can PPR pipes handle hot water?

Yes, PPR pipes can handle temperatures up to 95°C, making them ideal for hot water systems. - Are PPR pipes suitable for chemical transport?

Yes, PPR pipes are resistant to most chemicals, making them suitable for chemical transport in industries. - How long do PPR pipes last?

PPR pipes have a lifespan of over 50 years when installed and maintained properly. - Are PPR pipes safe for drinking water?

Yes, PPR pipes are made from non-toxic materials, ensuring the safe transportation of potable water.

By choosing PPR pipes for your piping systems, you ensure a long-lasting, reliable, and eco-friendly solution that meets the demands of modern infrastructure.