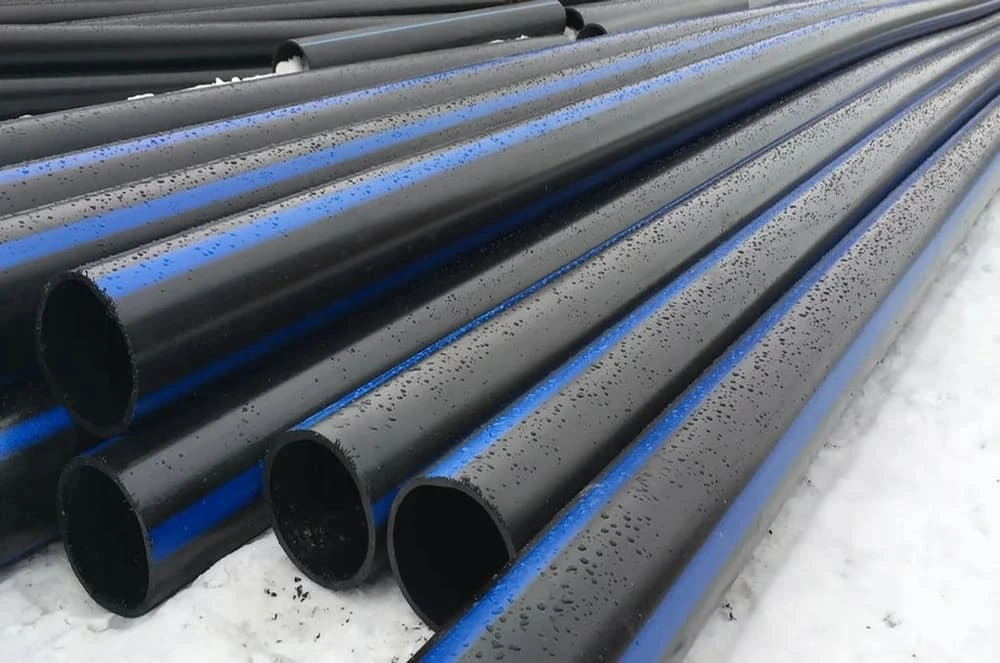

If you’re working with HDPE pipe, you already know the pipe alone doesn’t do much without the right fittings. And lately, more traders and manufacturers are pushing out fresh offers for HDPE pipe fittings—and many of them look pretty tempting. Whether you’re upgrading your irrigation setup, working on a new water supply project, or just topping up inventory for your shop, now might be the perfect time to grab a good deal.

Let’s break it all down. We’ll cover what HDPE pipe fittings are, what kind of offers are currently on the table, how to choose the right ones, and what to avoid.

What Exactly Are HDPE Pipe Fittings?

HDPE pipe fittings connect HDPE pipes together or link them with valves, tanks, or other pipe systems. These fittings come in different types—elbows, tees, reducers, end caps, couplers, flanges, and more. Some allow for welding, while others use compression or mechanical connections.

People choose HDPE pipe fittings because they create leak-free joints, last a long time, and resist chemicals and corrosion. They’re lightweight, strong, and work great underground or above ground in all sorts of industries—water, gas, sewage, mining, farming, and industrial processing.

What Do the Fresh Offers Look Like?

Right now, the market is buzzing with new stock and better prices on HDPE pipe fittings. Here’s why:

- More production from big manufacturers in China, Iran, India, and Turkey

- Stronger demand from infrastructure and agriculture projects

- Dealers trying to clear space in warehouses for newer models or fusion accessories

That’s good news for buyers. You can now find bulk discounts, package deals, or even free shipping (especially if you’re buying from nearby regions or through international trade platforms).

For example:

- Some sellers offer full HDPE pipe fitting kits—including couplers, elbows, and fusion tools

- Others give a discount if you order fittings with HDPE pipe in the same shipment

- A few traders now bundle in fusion machines or welding clamps as a bonus

These kinds of offers help small contractors and distributors save money, especially in regions where importing every part separately gets expensive.

Types of HDPE Pipe Fittings Available

Let’s take a quick tour through the most common types of HDPE pipe fittings you’ll see in the market:

1. Butt Fusion Fittings

These fittings join pipes using heat and pressure. You’ll need a fusion machine, but once installed, the joint becomes super strong and permanent.

2. Electrofusion Fittings

These use built-in electric coils to melt and fuse the pipe ends. It’s a cleaner and more precise process—great for tight spaces or projects that require full traceability.

3. Compression Fittings

Perfect for quick jobs or temporary setups. You just tighten them by hand or wrench—no welding needed.

4. Flange Adapters and Stub Ends

These let you connect HDPE pipe to metal systems, tanks, or valves. People often use them in factories, water treatment plants, or pump stations.

5. Socket Fusion Fittings

Smaller pipe sizes use socket fusion, where you heat and insert the pipe into the fitting. It’s simple and effective for low-pressure jobs.

What Should You Watch Out For?

As tempting as fresh offers might be, make sure you don’t get stuck with bad fittings. Here’s how to stay smart:

- Check the material: Look for PE100 or PE80—avoid recycled or low-grade plastics if quality matters.

- Confirm certifications: Reputable fittings should meet ISO 4427, EN 12201, or ASTM standards.

- Match your pipe specs: Make sure the pressure rating (PN6, PN10, PN16, etc.) and dimensions match your pipes.

- Inspect the finish: Good HDPE fittings look clean, smooth, and solid. If it looks weak or poorly molded, skip it.

Also, ask your supplier if the fittings work with your fusion machine brand. Not all brands play nicely with each other.

Where Are These Offers Coming From?

Most of the latest deals for HDPE pipe fittings are showing up from:

- Iran – They offer great prices and solid quality thanks to strong local HDPE production.

- China – Massive selection, strong logistics, and many OEM factories ready to ship fast.

- India and Turkey – Good for regional buyers, with fittings made to meet international specs.

A lot of these offers come through trade platforms like Alibaba, Made-in-China, or direct WhatsApp deals from suppliers. Just make sure to verify certifications and customer reviews before placing a large order.

How to Buy Smart

When you’re shopping around for HDPE pipe fittings, think long-term. Cheap fittings might save you a few dollars today but could cost you more in labor and replacement later.

Here’s how to shop smart:

- Compare 3–5 suppliers before placing an order.

- Request samples if possible.

- Look for full system offers—pipes, fittings, and fusion tools from one source.

- Ask about warranty and after-sales support.

Some sellers now offer HDPE systems with a 1- to 3-year warranty and even provide online guidance during installation.

Final Thoughts

There’s no doubt—right now is a great time to check out fresh offers for HDPE pipe fittings. Whether you’re a contractor handling large infrastructure projects or a distributor looking to stock up, the market gives you more variety and value than ever.

With the right supplier and the right fitting type, you can complete your HDPE systems quickly, safely, and affordably. Don’t wait until prices go up or stock runs out. Take advantage of these fresh deals while they last.

FAQ – HDPE Pipe Fittings

Q1: Can I mix HDPE pipe and fittings from different brands?

A: Sometimes, but it’s better to stick with one brand for best compatibility—especially with fusion fittings.

Q2: Are compression fittings as strong as fusion fittings?

A: Not really. Compression is easier to install, but fusion joints are much stronger and better for long-term use.

Q3: What’s the difference between PE80 and PE100 fittings?

A: PE100 is stronger and allows for thinner walls at the same pressure rating. Most new fittings use PE100.

Q4: Can I use HDPE pipe fittings for gas lines?

A: Yes, but make sure they’re certified for gas use—some fittings are water-only.

Q5: How long do HDPE pipe fittings last?

A: If installed correctly, they can last 50+ years. Just keep them away from direct sunlight if they’re not UV-protected.