Introduction

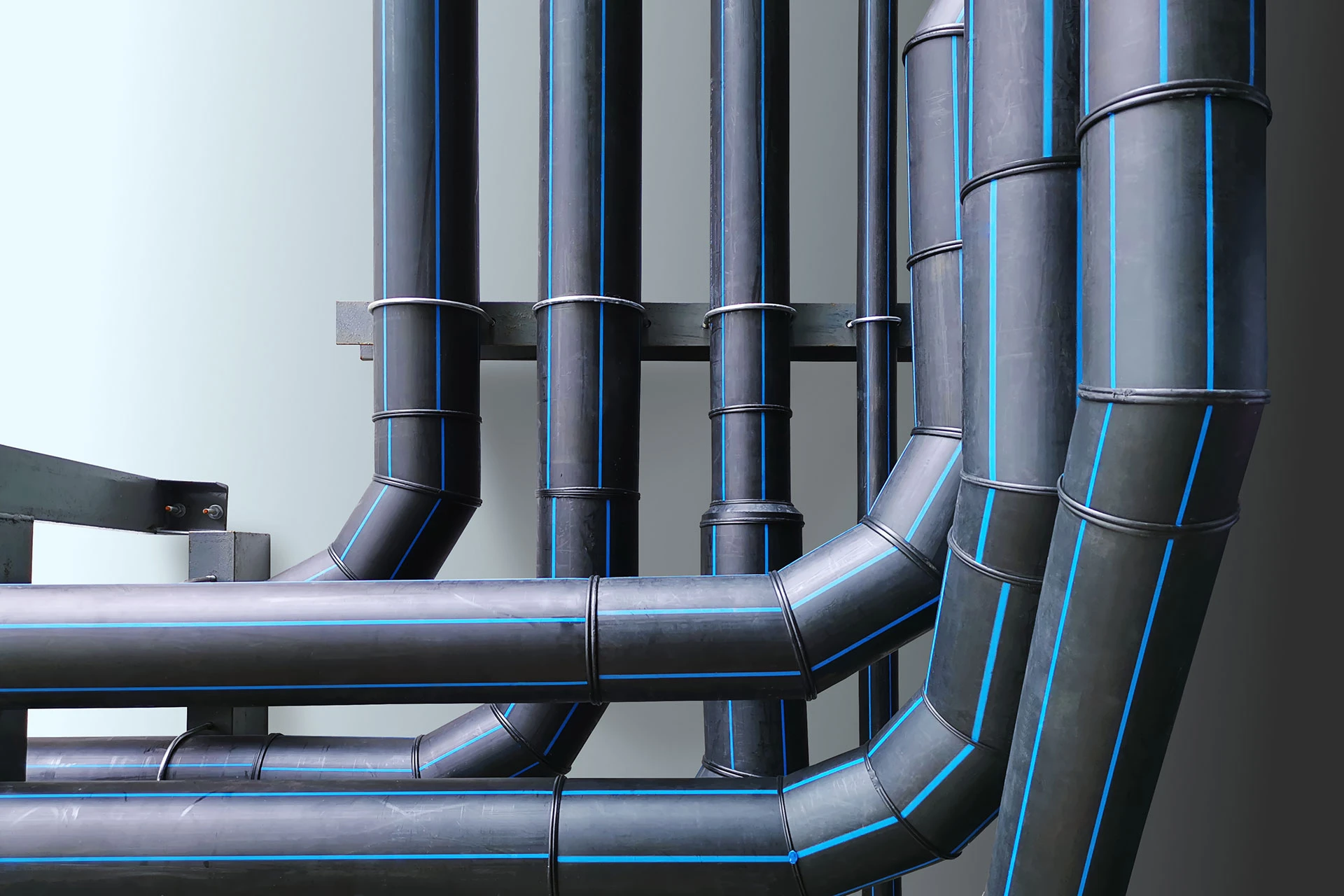

High-Density Polyethylene (HDPE) pipes are changing how we build plumbing and industrial systems. The 40mm size is especially useful because it’s strong, flexible, and affordable. Whether you need pipes for your home’s water supply or for a factory, 40mm HDPE pipe is great choice.

In this guide, we’ll explain:

✔ What makes 40mm HDPE pipes special

✔ How they’re used in homes and industries

✔ Why they’re better than old-fashioned metal or PVC pipes

✔ Tips for installing them the right way

✔ Answers to common questions

By the end, you’ll see why builders, plumbers, and homeowners prefer HDPE pipes.

Why Pick 40mm HDPE Pipe?

HDPE pipes are tough but lightweight. Here’s why the 40mm size is so popular:

✅ Won’t rust or corrode – Unlike metal pipes, HDPE doesn’t break down from water or chemicals.

✅ Easy to install – They’re light and bend slightly, making them simpler to work with than stiff pipes.

✅ No leaks – The joints are melted together, so water can’t escape like it sometimes does with screwed-in pipes.

✅ Lasts 50+ years – They resist sunlight, scratches, and extreme hot or cold weather.

✅ Good for the environment – They’re made from recycled plastic and use less energy to make than metal pipes.

Home Uses for 40mm HDPE Pipe

1. HDPE Water Pipe

- Brings clean water to sinks and showers.

- Works for both cold and warm water (but not boiling water).

2. Drainage & Sewage

- Carries wastewater away without rotting or cracking.

- Great for rainwater systems in gardens.

3. Gas Lines (If Approved)

- Some types can safely carry gas for stoves and heaters.

4. Garden Irrigation

- Perfect for sprinklers because they don’t break down in sunlight.

Factory & Industrial Uses

1. Mining Operations

- Moves muddy water and minerals without wearing out.

2. Chemical Plants

- Safely carries strong acids and other chemicals.

3. Air Pressure Systems

- Handles compressed air in workshops.

4. Protecting Underground Cables

- Keeps electrical wires safe from water and damage.

Connectors for 40mm HDPE Pipe

To build a good pipe system, you’ll need:

🔹 Elbows – For turning corners (90° or 45° angles).

🔹 T-Connectors – For splitting pipes into different directions.

🔹 Straight Couplers – For joining two pipes together.

🔹 End Caps – For closing off a pipe.

Helpful Tip: The best way to connect HDPE pipes is by melting the ends together (called “welding”). This makes the strongest seal.

How to Install Them Right

- Dig a Clean Trench – Remove rocks and sharp objects so the pipe won’t get damaged.

- Leave Some Space – Pipes expand in heat, so don’t install them too tightly.

- Melt Joints Properly – Use the right tools to fuse connections so they won’t leak.

- Test Before Use – Check for leaks by running water through the pipes first.

HDPE vs. Other Pipe Materials

HDPE Pipes

- Last over 50 years

- Bend without breaking

- Never rust

- Easy to install

- Medium cost

PVC Pipes

- Last 25-40 years

- More rigid

- Can crack in cold weather

- Cheaper but weaker

Metal Pipes

- Rust over time (15-30 years)

- Very stiff

- Hard to install

- Most expensive

The Winner? HDPE is best for most jobs because it lasts longest and doesn’t break easily.

5 Common Questions

1. Can HDPE pipe handle hot water?

Yes, but only up to 60°C (140°F). For hotter water, use different pipes.

2. How long do they last?

Over 50 years if installed correctly.

3. Are they safe for drinking water?

Yes! They’re approved for clean water and don’t release harmful chemicals.

4. Can I connect HDPE to other pipe types?

Yes, with special adapters, but welded HDPE connections are strongest.

5. How much pressure can they handle?

Most 40mm HDPE pipes handle 10-16 times normal water pressure.

Final Thoughts

40mm HDPE pipes are smart for homes and businesses. They don’t rust, last decades, and are easier to work with than metal or PVC. Whether you’re fixing your house’s plumbing or building a factory system, HDPE is a reliable choice.

Need HDPE pipes? Contact a local supplier to get started!