Introduction to Brass PEX Fittings

Brass PEX fittings BS EN ISO 22391 are essential components in modern plumbing systems. Designed for use with PEX (cross-linked polyethylene) tubing, these fittings offer a durable, corrosion-resistant, and easy-to-install solution for residential and commercial plumbing applications. Whether you’re working on a new construction project or upgrading an existing plumbing system, brass PEX fittings are an ideal choice due to their strength, reliability, and ease of use.

What Are Brass PEX Fittings?

Brass PEX fittings are used to connect PEX tubing to other pipes, fixtures, or appliances. These fittings are made from brass, a durable and corrosion-resistant material, and are designed to ensure a secure, leak-proof connection. Brass PEX fittings are widely used in plumbing systems for water distribution, radiant heating, and other applications.

Advantages of Brass PEX Fitting

Brass PEX fittings offer several benefits, making them a popular choice for both professionals and DIY enthusiasts. Here are some of the key advantages:

1. Durability

Brass known for its long-lasting durability and resistance to corrosion. Brass PEX fittings can withstand the wear and tear of everyday use and are resistant to rust, ensuring a longer lifespan than plastic alternatives.

2. Versatility

Brass PEX fittings are compatible with both PEX-A, PEX-B, and PEX-C tubing, making them a versatile choice for various types of PEX systems. They can also be in a wide range of plumbing applications, including potable water systems, radiant floor heating, and hydronic heating systems.

3. Leak-Proof Connections

When installed correctly, brass PEX fittings create a secure, leak-proof connection. This is particularly important in water distribution systems, where leaks can lead to water damage, increased utility bills, and costly repairs.

4. Easy Installation

Brass PEX fittings are simple to install, requiring only basic tools such as a crimp tool or cinch tool. The installation process is fast and straightforward, making it a convenient option for both professionals and homeowners.

5. Corrosion Resistance

Brass naturally resists corrosion, which means these fittings will remain in good condition even when exposed to water and various environmental conditions. This makes them a great choice for both indoor and outdoor plumbing systems.

Types of Brass PEX Fitting

Brass PEX fittings come in a variety of shapes and sizes, each serving a different purpose in a plumbing system. Some common types of brass PEX fittings include:

1. Brass PEX Couplings

Couplings used to connect two sections of PEX tubing. They are commonly used when extending or repairing a section of the plumbing system.

2. Brass PEX Elbows

Elbows designed to allow for a change in direction in the PEX tubing, typically at a 90-degree angle. These fittings are ideal for navigating tight spaces or corners.

3. Brass PEX Tees

Tees allow for the creation of a branch in the PEX tubing, splitting the water flow into two directions. This fitting is useful when you need to supply water to multiple fixtures from a single line.

4. Brass PEX Adapters

Adapters used to connect PEX tubing to other types of pipes, such as copper, PVC, or CPVC. This fitting is essential when transitioning between different plumbing materials.

5. Brass PEX Valves

Brass PEX valves allow for control over the water flow in a PEX system. These valves can be used to shut off water to specific sections of the plumbing system for maintenance or repairs.

How to Install Brass PEX Fitting

Installing brass PEX fitting is a simple process that requires a few basic tools. Here’s a step-by-step guide to installing these fittings:

1. Cut the PEX Tubing

Start by cutting the PEX tubing to the desired length using a PEX cutter. Ensure that the cut is straight and clean to avoid any issues during installation.

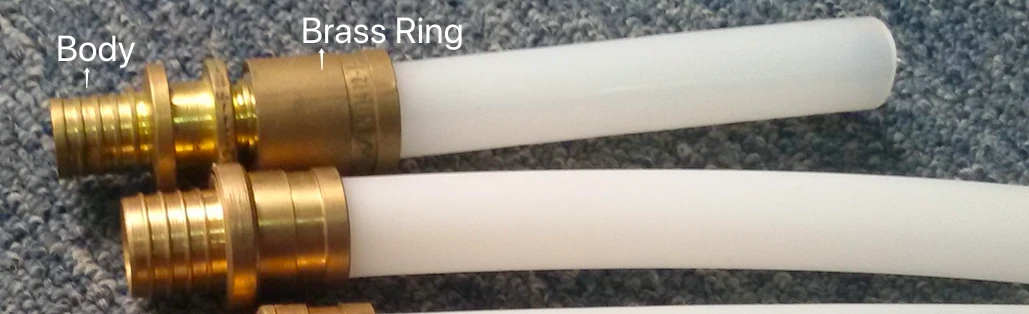

2. Insert the Fitting

Insert the brass PEX fitting into the end of the PEX tubing. Make sure the tubing fits snugly over the fitting to ensure a secure connection.

3. Secure with a Crimp Ring or Clamp

Slide a crimp ring or cinch clamp over the end of the PEX tubing. Use a crimp tool or cinch tool to tighten the ring or clamp around the tubing and fitting, securing the connection.

4. Test the Connection

Once the fitting is installed, test the connection by turning on the water supply and checking for leaks. If there no leaks, the fitting has been properly installed.

Applications of Brass PEX Fittings

Brass PEX fitting are used in a wide range of plumbing applications, thanks to their durability and versatility. Some common applications include:

1. Water Distribution Systems

Brass PEX fitting widely used in potable water systems to supply hot and cold water throughout homes and commercial buildings. Their corrosion resistance and leak-proof design make them ideal for this purpose.

2. Radiant Floor Heating

Radiant floor heating systems use PEX tubing to circulate heated water beneath floors, providing efficient and even heating. Brass PEX fitting commonly used in these systems to connect the tubing to the heating source and other components.

3. Hydronic Heating Systems

In hydronic heating systems, PEX tubing is used to transport heated water to radiators or baseboard heaters. Brass PEX fitting ensure secure and reliable connections in these systems.

4. Plumbing Repairs

Brass PEX fitting are often used for repairs in existing plumbing systems, allowing for quick and easy fixes without the need for soldering or specialized tools.

Conclusion

Brass PEX fittings are a reliable, durable, and versatile solution for modern plumbing systems. Their easy installation, resistance to corrosion, and ability to create leak-proof connections make them a preferred choice for both professionals and DIY enthusiasts. Whether you’re installing a new plumbing system or making repairs to an existing one, brass PEX fitting provide the strength and reliability needed to ensure long-lasting performance.