Introduction

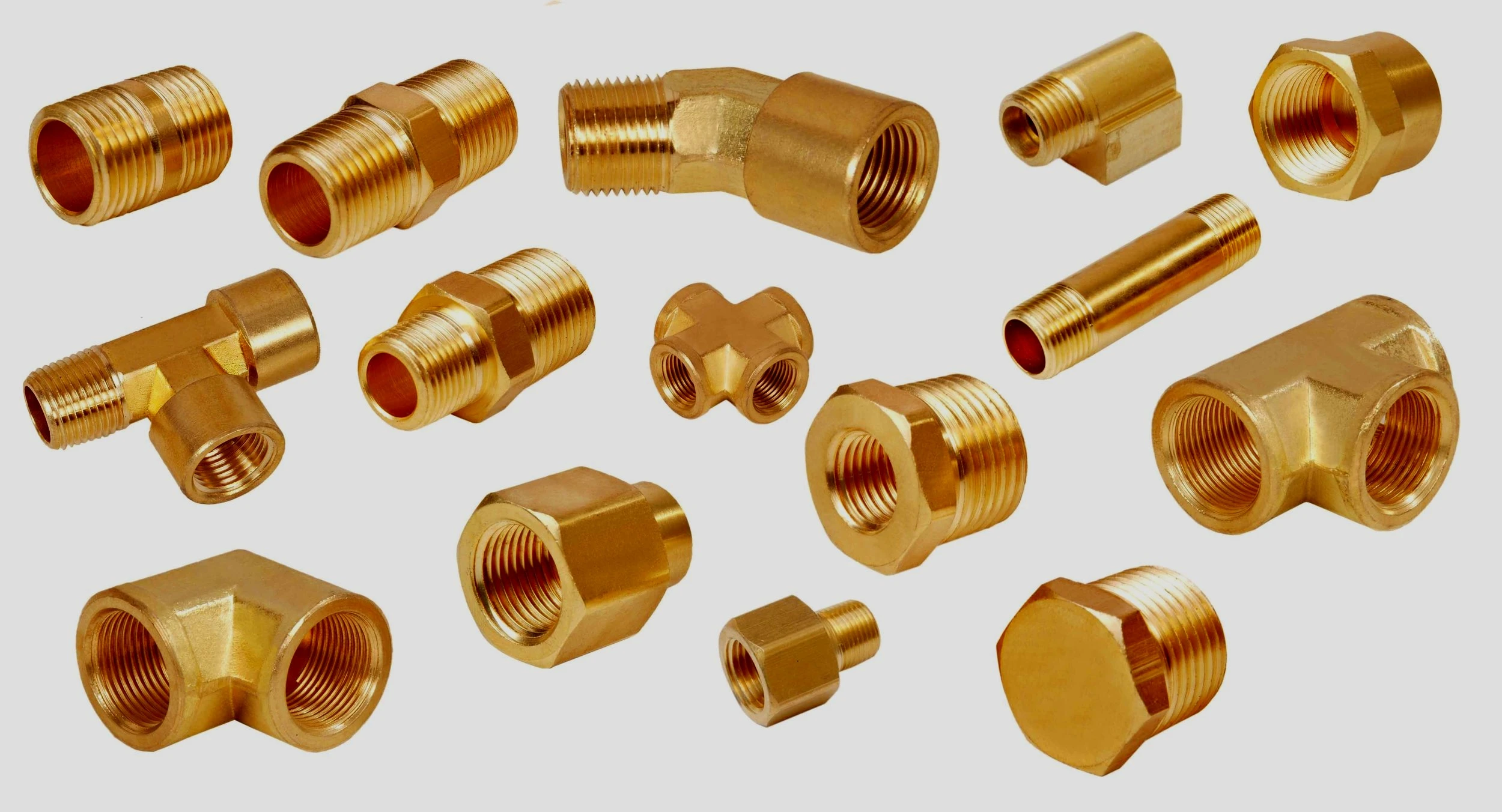

Brass pipe fittings BS 7291 are essential components in plumbing and piping systems, known for their durability, reliability, and aesthetic appeal. They play a crucial role in connecting pipes, controlling fluid flow, and ensuring the efficiency of various systems. This guide delves into the types, benefits, applications, and installation of brass pipe fittings, providing valuable insights for both professionals and DIY enthusiasts.

1. What Are Brass Pipe Fittings?

1.1 Definition and Purpose

Brass pipe fittings are connectors made from brass, used to join sections of pipes or tubes in a plumbing or piping system. T

1.2 Key Features of Brass Pipe Fittings

- Durability: Brass is known for its strength and resistance to corrosion, making it ideal for long-term use.

- Versatility: Brass fittings are available in a wide range of types and sizes to accommodate different piping needs.

- Aesthetic Appeal: The golden hue of brass adds a touch of elegance to plumbing systems, especially in visible installations.

2. Benefits of Using Brass Pipe Fittings

2.1 Strength and Durability

Brass fittings are highly durable and can withstand high pressures and temperatures. Their robustness makes them suitable for demanding environments, including industrial and commercial applications.

2.2 Corrosion Resistance

Brass is resistant to corrosion and rust, which helps extend the lifespan of the fittings and prevents leaks and system failures. This makes brass an excellent choice for both water and gas systems.

2.3 Ease of Installation

Brass pipe fittings are relatively easy to install. Many fittings come with threaded connections that can be tightened with standard tools, reducing the need for specialized equipment.

2.4 Low Maintenance

Brass fittings require minimal maintenance compared to other materials. Regular cleaning and occasional inspection are usually sufficient to keep them in good working condition.

3. Types of Brass Pipe Fittings

3.1 Elbows

Elbows are used to change the direction of the pipe. They are available in various angles, such as 45 degrees and 90 degrees, to facilitate flexible routing of the piping system.

3.2 Couplings

Couplings connect two sections of pipe together. They come in different sizes and configurations, including straight and reducing couplings, to match the pipe dimensions and desired flow direction.

3.3 Tees

Tees allow for branching the pipe into two directions.

3.4 Adapters

Adapters enable the connection of pipes with different types of threads or fittings. They are essential for integrating various components within a piping system.

3.5 Plugs and Caps

Plugs and caps are used to seal the ends of pipes or fittings. They are useful for terminating a line or capping off unused connections.

3.6 Bushings

They are helpful when connecting pipes of different diameters or adapting to various pipe sizes.

4. Applications of Brass Pipe Fittings

4.1 Residential Plumbing

Their durability and reliability make them a popular choice for home plumbing projects.

4.2 Commercial Plumbing

Their strength and corrosion resistance are essential for handling high traffic and demanding conditions.

4.3 Industrial Applications

In industrial settings, brass pipe fittings are used for various processes, including fluid transfer, HVAC systems, and machinery connections. Their ability to withstand harsh environments makes them suitable for industrial applications.

5. Selecting the Right Brass Pipe Fittings

5.1 Determine the Application

Consider the specific requirements of your plumbing or piping system. Different applications may require different types and sizes of fittings.

5.2 Check Compatibility

Ensure that the brass fittings are compatible with the pipes and other components in your system. Verify that the fittings match the pipe size, thread type, and pressure rating.

5.3 Quality and Standards

Choose fittings that meet industry standards and are made from high-quality brass. Reliable manufacturers often provide certifications and specifications to ensure the quality of their products.

5.4 Consider the Finish

Brass fittings come in various finishes, such as polished, brushed, or antique. Select a finish that matches the aesthetic of your system and suits your maintenance preferences.

6. Installation Tips for Brass Pipe Fittings

6.1 Preparation

- Inspect the Fittings: Check for any damage or defects before installation.

- Clean the Pipes: Ensure that the pipes are clean and free of debris to ensure a proper seal.

6.2 Installation Process

- Apply Thread Sealant: For threaded fittings, apply thread sealant tape or compound to prevent leaks.

- Tighten Connections: Use the appropriate tools to tighten the fittings, ensuring a secure and leak-proof connection.

6.3 Final Checks

- Inspect for Leaks: After installation, turn on the system and check for any leaks or issues.

- Verify Alignment: Ensure that the pipes and fittings are properly aligned and supported.

7. Maintenance and Care

7.1 Regular Cleaning

Dust and clean brass fittings regularly to maintain their appearance and functionality. Use a soft cloth and a non-abrasive cleaner designed for brass.

7.2 Addressing Corrosion

If you notice any signs of corrosion or tarnish, use a brass polish to restore the finish. Follow the manufacturer’s recommendations for cleaning and polishing.

7.3 Inspect for Wear

Periodically inspect the fittings for signs of wear or damage. Address any issues promptly to prevent leaks or system failures.

8. Conclusion

Brass pipe fittings offer a combination of strength, durability, and aesthetic appeal that makes them a preferred choice for various plumbing and piping applications. By understanding the different types of brass fittings, their benefits, and proper installation and maintenance practices, you can ensure a reliable and efficient piping system.