Copper solder ring fittings are widely us in plumbing systems due to their reliability, durability, and ease of installation. These fittings contain a pre-applied ring of solder within the fitting, which melts when heated and forms a watertight seal around the joint. Copper solder ring fittings are design to simplify the installation process, making them an ideal choice for both professionals and DIY enthusiasts. In this article, we’ll explore how copper solder ring fittings work, their benefits, and why they are a preferred option for many plumbing applications.

What Are Copper Solder Ring Fittings?

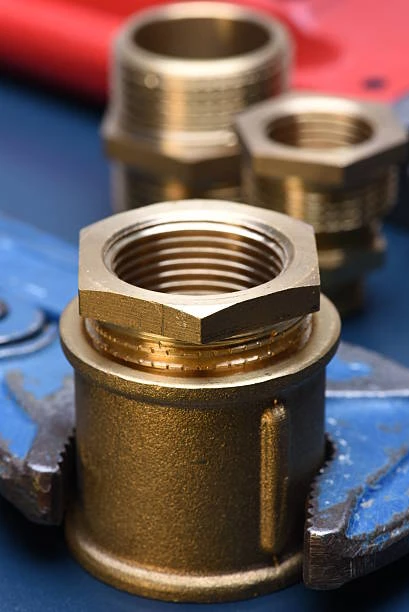

Copper solder ring fittings, also known as end feed fittings, are plumbing components used to connect copper pipes. These fittings have a small ring of solder pre-applied to the inside of the fitting. When the fitting is heat with a propane or butane torch, the solder melts and flows into the joint between the pipe and fitting, creating a secure and leak-free connection.

These fittings come in various shapes and sizes, such as elbows, tees, couplers, and reducers, making them suitable for a wide range of plumbing projects. They are commonly us in both domestic and commercial water supply systems, as copper is known for its corrosion resistance and ability to handle high temperatures and pressures.

How Copper Solder Ring Fittings Work

The installation process for copper solder ring fittings is straightforward, thanks to the pre-applied solder. To install the fittings, the copper pipes must first be cut to the desir length using a pipe cutter. The ends of the pipe and the inside of the fitting should be cleaned thoroughly with a wire brush or emery cloth to remove any oxidation or debris. This step is essential to ensure that the solder adheres properly to the copper surface.

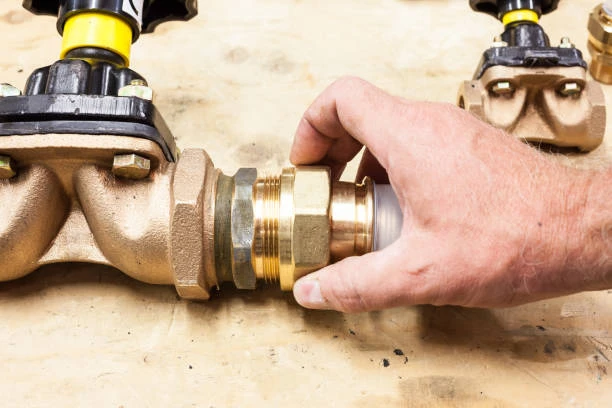

Once the pipe and fitting are clean, the pipe is insert into the fitting. A torch is then us to heat the fitting evenly. As the fitting heats up, the solder ring inside melts and flows into the joint by capillary action, forming a strong, watertight bond. After the fitting has cooled, the joint can be inspect to ensure that the solder has completely sealed the connection.

Benefits of Using Copper Solder Ring Fittings

Copper solder ring fittings offer several advantages over other types of fittings, making them a popular choice in plumbing systems. Some of the key benefits include:

- Ease of Installation: The pre-applied solder eliminates the need for measuring and applying solder manually, reducing the chance of error and making the installation process quicker and easier. This is particularly helpful for DIY projects or when working in tight spaces.

- Durability: Copper is known for its strength and corrosion resistance, which ensures that copper solder ring fittings will provide a long-lasting, reliable connection. These fittings are ideal for high-pressure systems and can handle both hot and cold water applications.

- Leak-Free Joints: When properly installed, copper solder ring fittings create a permanent, watertight seal that prevents leaks. The solder flows evenly into the joint, ensuring a strong connection that can withstand the pressures of a plumbing system.

- Cost-Effective: While copper solder ring fittings may have a slightly higher initial cost compared to other fittings, their durability and long lifespan make them a cost-effective solution in the long run. The fittings require minimal maintenance and reduce the need for repairs or replacements over time.

- Versatility: These fittings come in a variety of shapes and sizes, allowing plumbers to tackle a wide range of plumbing tasks. Whether connecting straight pipes, changing direction, or reducing pipe sizes, there is a copper solder ring fitting available for the job.

Key Considerations for Installation

While copper solder ring fitting are relatively easy to install, there are some important considerations to keep in mind to ensure a successful installation:

- Proper Cleaning: Cleaning the pipe and fitting is crucial for a strong solder joint. Any dirt, oxidation, or grease on the surfaces can prevent the solder from adhering properly, leading to leaks. Be sure to clean both the pipe and fitting thoroughly before heating.

- Even Heating: When using a torch to heat the fitting, it’s important to apply the heat evenly around the fitting to ensure that the solder melts uniformly. Uneven heating can result in incomplete solder flow, which can weaken the joint.

- Correct Pipe Insertion: The pipe should be insert fully into the fitting to ensure a secure connection. If the pipe is not properly seat, the solder may not flow correctly into the joint, leading to potential leaks.

- Inspection: After the fitting has cooled, inspect the joint to ensure that the solder has flowed evenly around the entire joint. Any gaps or voids in the solder could indicate an incomplete seal, which may need to be reheat and re-soldered.

Common Applications of Copper Solder Ring Fittings

Copper solder ring fitting are us in a wide range of plumbing applications due to their versatility and reliability. Some of the most common uses include:

Safety Considerations

Working with a torch and hot metal requires careful attention to safety. Here are some safety tips to keep in mind when installing copper solder ring fitting:

- Wear Protective Gear: Always wear safety goggles, heat-resistant gloves, and long sleeves to protect yourself from burns and sparks.

- Ensure Proper Ventilation: When soldering, especially indoors, make sure the work area is well-ventilat to avoid inhaling fumes from the flux or solder.

- Keep a Fire Extinguisher Nearby: Have a fire extinguisher on hand in case of accidental fires, especially when working in confined spaces or near flammable materials.

- Avoid Overheating: Overheating the fitting can burn off the flux, which is necessary to prevent oxidation and ensure proper solder flow. If the flux burns off, the fitting may ne to be clean and re-fluxed before continuing.

Conclusion

Copper solder ring fittings provide an efficient, reliable, and long-lasting solution for connecting copper pipes in plumbing systems. Their pre-applied solder ring simplifies the installation process, making them ideal for both professionals and DIYers. With their durability, leak-free performance, and versatility, copper solder ring fitting are a go-to choice for a wide range of plumbing applications.

By following proper installation practices and adhering to safety guidelines, you can ensure that your copper solder ring fitting provide a secure, watertight connection that will last for years to come.

FAQ

1. What is the difference between copper solder ring fitting and traditional solder fitting?

Copper solder ring fitting come with a pre-applied ring of solder inside the fitting, while traditional solder fitting require the user to manually apply solder during installation.

2. Can copper solder ring fittings be us with gas lines?

Yes, copper solder ring fitting can be us with gas lines, but it’s important to ensure that the fitting are rated for gas use and that the installation complies with local codes and regulations.

3. Do copper solder ring fitting require flux?

Yes, flux should still be applied to the pipe and fitting before heating, as it helps clean the surfaces and allows the solder to flow smoothly into the joint.

4. Are copper solder ring fitting suitable for both hot and cold water systems?

Yes, copper solder ring fitting are design to handle both hot and cold water systems and can withstand high temperatures and pressures.

5. How do I know if the solder has fully sealed the joint?

A properly sealed joint will have an even bead of solder around the fitting. After cooling, inspect the joint for any gaps or voids in the solder. If necessary, reheat and re-solder the joint to ensure a complete seal.