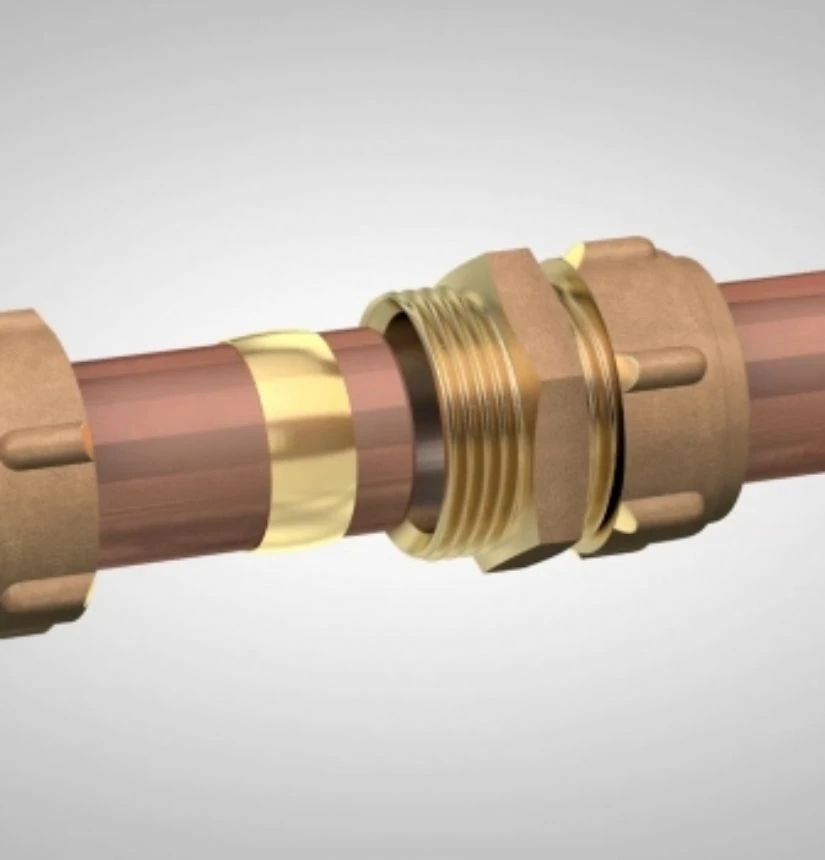

What Are Copper PEX Press Fittings?

Copper PEX press fittings DIN 16836 are a revolutionary plumbing solution designed for use with PEX (cross-linked polyethylene) piping systems. These fittings combine the durability of copper with the flexibility and efficiency of PEX pipes, providing an easy, reliable way to connect and secure water lines without the need for soldering or crimping.

Advantages of Using Copper PEX Press Fittings

1. Time-Saving Installation

One of the biggest benefits of copper PEX press fittings is how fast they are to install. Unlike traditional methods that involve welding or soldering, these fittings can be pressed into place in seconds with a specialized tool. This reduces labor costs and speeds up project timelines significantly.

2. Leak-Proof Sealing

Copper PEX press fittings ensure a secure, leak-proof connection. The press fitting system uses a stainless steel sleeve to compress the fitting around the PEX pipe, creating a durable seal that resists leaks and water damage.

3. Corrosion Resistance

Since copper is naturally resistant to corrosion, these fittings offer long-term durability in plumbing systems. This makes copper PEX press fittings ideal for both residential and commercial applications, especially in areas where water quality may cause corrosion issues in other materials.

4. Flexibility of PEX Pipes

The combination of copper fittings and PEX piping offers unparalleled flexibility. PEX pipes can bend and adapt to different angles, reducing the need for additional fittings and joints. This simplifies the design and installation of plumbing systems.

Common Applications of Copper PEX Press Fittings

1. Residential Plumbing

In homes, copper PEX press fitting are commonly used for hot and cold water supply lines. Their ease of installation and resistance to leaks make them ideal for tight spaces and retrofitting projects.

2. Commercial Buildings

In commercial settings, these fittings are utilized in large-scale plumbing systems due to their ability to handle high water pressures and temperatures. The corrosion resistance of copper also makes them ideal for long-term use in public buildings.

3. HVAC Systems

Copper PEX press fittings are also frequently used in HVAC systems, connecting pipes that carry hot and cold water to heating and cooling units. The flexibility of PEX makes it easier to route pipes in tight areas, while the copper fittings ensure durability.

How to Install Copper PEX Press Fitting

1. Prepare the Pipe

Start by cutting the PEX pipe to the required length using a pipe cutter. Ensure the edges are smooth and free from burrs.

2. Insert the Fitting

Place the copper press fitting onto the end of the PEX pipe. Make sure the pipe is fully seated in the fitting to ensure a secure connection.

3. Use the Press Tool

Utilize a press tool to compress the stainless steel sleeve around the fitting. Ensure the tool is calibrated for the correct pipe size to prevent damage or under-compression.

4. Inspect the Joint

Once the press is complete, inspect the joint to ensure the fitting is fully seated and the sleeve is properly compressed. If done correctly, the connection will be watertight and secure.

Why Choose Copper PEX Press Fittings Over Traditional Methods?

Traditional plumbing methods, such as soldering copper pipes or using plastic fittings, have their own limitations. Copper PEX press fitting offer a modern alternative by combining the best features of copper’s durability with the ease of PEX installation. This makes them an attractive option for both DIY homeowners and professional plumbers.

1. No Open Flames

Since no soldering is required, there’s no need for open flames, which reduces the risk of fire. This also means press fittings can be installed in areas where traditional soldering would be difficult or dangerous, such as near flammable materials.

2. Reliable Under Pressure

Copper PEX press fitting can handle high water pressure, making them suitable for a wide range of applications. Whether it’s a residential home or a high-rise building, these fittings provide a reliable solution.

Maintenance and Longevity

Copper PEX press fitting require minimal maintenance after installation. They resist corrosion, and because the press connection is so secure, there’s little risk of leaks developing over time. With proper installation, these fittings can last for decades, offering a long-term, cost-effective plumbing solution.

Conclusion

Copper PEX press fittings are a top choice for modern plumbing systems, combining ease of installation with durability and leak resistance. Whether you’re working on a residential or commercial project, these fittings offer a time-saving, reliable solution that outperforms traditional plumbing methods. Their flexibility, corrosion resistance, and secure sealing make them a must-have for anyone looking to upgrade their plumbing systems efficiently.