Copper solder ring fittings are one of the most widely used types of plumbing fittings due to their ease of use, durability, and reliability. These fittings, also known as capillary or pre-soldered fittings, designed to simplify the plumbing process by incorporating a small amount of solder within the fitting. When heat applied, the solder melts, creating a secure and leak-proof joint between copper pipes.

In this article, we will explore what copper solder ring fittings are, how they work, their benefits, common applications, and tips for installation. We will also address the environmental impact and the growing popularity of these fittings in both residential and commercial plumbing systems.

What Are Copper Solder Ring Fittings?

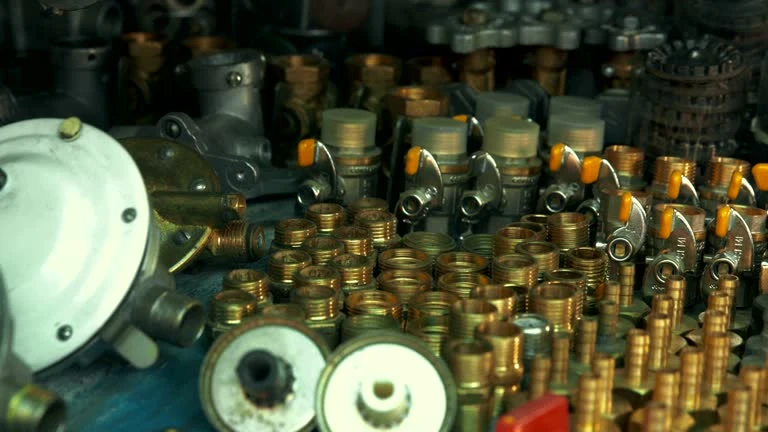

Copper solder ring fittings specially designed plumbing components us to join copper pipes.

This type of fitting is popular in plumbing because it simplifies the process of joining copper pipes. Instead of manually applying solder to the joint, the plumber only needs to clean the pipe, insert it into the fitting, and heat the joint with a torch. The pre-soldered ring melts and flows into the joint, creating a strong, durable, and watertight connection.

How Do Copper Solder Ring Fittings Work?

The basic principle behind copper solder ring fittings is capillary action. When heat is applied to the fitting and the copper pipe, the solder inside the fitting melts and is drawn into the joint between the pipe and fitting by capillary action. This ensures that the solder spreads evenly and fills the gap between the surfaces, forming a tight seal.

Here’s how the process works in a few simple steps:

- Preparation: The copper pipes must be cut to the desir length, and both the pipe and the inside of the solder ring fitting must be cleaned thoroughly. This is usually done with an abrasive pad or wire wool to remove any dirt, grease, or oxidation.

- Assembly: Once clean, the copper pipe is inserted into the solder ring fitting. The plumber ensures that the pipe is fully seated inside the fitting to create a proper joint.

- Heating: Using a propane or butane torch, the joint is heat until the solder inside the fitting melts. The heat should be applied evenly around the fitting to ensure the solder flows properly.

- Cooling: After the solder has melt and filled the joint, the heat is removed, and the joint is allowed to cool. As it cools, the solder solidifies, forming a strong, leak-proof bond.

Benefits of Copper Solder Ring Fittings

Copper solder ring fittings offer several advantages over other types of plumbing fittings, making them a popular choice among professional plumbers and DIY enthusiasts alike. Some of the key benefits include:

- Ease of Installation

One of the primary reasons copper solder ring fittings are so popular is their simplicity. The pre-applied solder eliminates the need for manually applying solder, which can be challenging for beginners. This makes the installation process quicker and more straightforward, especially for those who are new to plumbing. - Leak-Proof Joints

The use of pre-solder rings ensures that solder is evenly distribut around the joint, reducing the risk of leaks. The capillary action that draws the solder into the joint helps create a strong, durable bond that can withstand high water pressures and temperature changes. - Durability and Longevity

Copper is known for its strength and resistance to corrosion, making it an ideal material for plumbing systems. Copper solder ring fittings are highly durable and can last for decades without the need for replacement. This makes them a cost-effective choice in the long run. - Versatility

Copper solder ring fittings are available in a wide range of sizes and configurations, making them suitable for various applications, including domestic water supply, central heating systems, and gas lines. They can be us in both residential and commercial plumbing systems. - Aesthetic Appeal

Copper fittings are often chosen for their aesthetic appeal, especially in exposed plumbing systems. The bright, polished finish of copper can enhance the appearance of installations where visible pipework is a consideration, such as in modern industrial-style interiors.

Common Applications of Copper Solder Ring Fittings

Copper solder ring fittings are us in a variety of plumbing applications, both in residential and commercial settings. Some common uses include:

- Domestic Water Supply Systems

Copper solder ring fittings are widely us in domestic water supply systems due to their reliability and resistance to corrosion. They are suitable for both hot and cold water supply lines, ensuring leak-free connections that can handle varying water pressures and temperatures. - Central Heating Systems

These fittings are also commonly us in central heating systems, where they connect copper pipes that carry hot water from the boiler to radiators and other heating elements. The ability of copper to withstand high temperatures makes it an ideal choice for these applications. - Gas Lines

In addition to water systems, copper solder ring fittings can be us in gas supply lines. However, it’s important to ensure that the fittings used for gas installations comply with local safety regulations and standards. - Industrial and Commercial Plumbing

In industrial and commercial settings, copper solder ring fittings are often us in plumbing systems that require high durability and resistance to corrosion. They are suitable for use in a wide range of environments, including factories, hospitals, and office buildings. - DIY Plumbing Projects

Because of their ease of use, copper solder ring fittings are a popular choice for DIY plumbing projects. Homeowners can use them to repair or replace sections of their plumbing system without needing advanced plumbing skills.

Tips for Installing Copper Solder Ring Fittings

While copper solder ring fittings are relatively easy to install, there are a few key tips to keep in mind to ensure a successful and leak-free joint:

- Proper Cleaning

Cleaning the copper pipes and fittings is critical for a successful installation. Any dirt, grease, or oxidation on the pipe or fitting can prevent the solder from flowing properly and may result in a weak joint. Use a wire brush or abrasive pad to clean the surfaces thoroughly. - Even Heating

When heating the joint, make sure to apply the heat evenly around the fitting. Uneven heating can cause the solder to flow unevenly, leading to weak spots in the joint. Move the torch in a circular motion to ensure uniform heating. - Check for Proper Fit

Before heating the joint, ensure that the copper pipe is fully seat inside the solder ring fitting. A loose or improperly seated pipe can lead to a weak joint or leaks after installation. - Allow Time to Cool

After the solder has melted and filled the joint, allow the fitting to cool naturally. Do not disturb the joint until it has fully solidified, as this could weaken the bond. - Inspect the Joint

Once the joint has cooled, inspect it for any visible gaps or imperfections. If the solder has not flowed properly, you may need to reheat the joint and apply additional solder.

Environmental Considerations

Copper solder ring fittings are not only durable and long-lasting but also environmentally friendly. Copper is a highly recyclable material, and old copper fittings can often be recycled and reus in new applications. Additionally, because copper plumbing systems have a long lifespan, they help reduce the need for frequent replacements, which contributes to resource conservation.

Lead-free solder is commonly us with modern copper fittings, further reducing the environmental impact and making these fittings a safer choice for drinking water systems.

Conclusion

Copper solder ring fittings offer an efficient, reliable, and durable solution for plumbing systems. Their ease of installation, combined with their leak-proof performance and long lifespan, makes them an ideal choice for both professional plumbers and DIY enthusiasts. Whether you’re working on a domestic water supply system, central heating, or a gas line, copper solder ring fittings provide the strength and reliability needed for high-performance plumbing.

As awareness of environmental sustainability grows, the recyclability of copper and the use of lead-free solder further enhance the appeal of these fittings in modern plumbing applications. By following proper installation techniques and ensuring high-quality materials, you can achieve a secure and durable plumbing system that will last for years to come.

FAQs

- What are copper solder ring fitting used for?

Copper solder ring fitting are us to join copper pipes in plumbing systems, providing a secure and leak-proof connection for water, heating, and gas systems. - How do copper solder ring fitting work?

These fittings contain a pre-applied ring of solder that melts when heated. The solder is drawn into the joint by capillary action, creating a strong and durable connection between the pipe and fitting. - Are copper solder ring fitting suitable for DIY plumbing projects?

Yes, copper solder ring fitting are easy to install and are a popular choice for DIY plumbing projects due to their pre-soldered design and straightforward installation process. - Can copper solder ring fitting be us in gas lines?

Yes, copper solder ring fitting can be us in gas lines, but it’s important to ensure they meet local safety standards and regulations for gas installations. - What are the environmental benefits of copper solder ring fitting?

Copper is a recyclable material, and the use of lead-free solder makes these fittings an environmentally friendly option for plumbing systems, reducing waste and resource consumption.