In a significant shift in the global copper fittings market, India has transitioned from being a leading exporter to an importer of copper fittings in just three years. This transformation has created opportunities for neighboring Pakistan, which has stepped in to fill the void left by India’s changing trade dynamics. In this article, we will explore the reasons behind this shift, the implications for both countries, and the future of the copper fittings market.

Understanding Copper Fittings

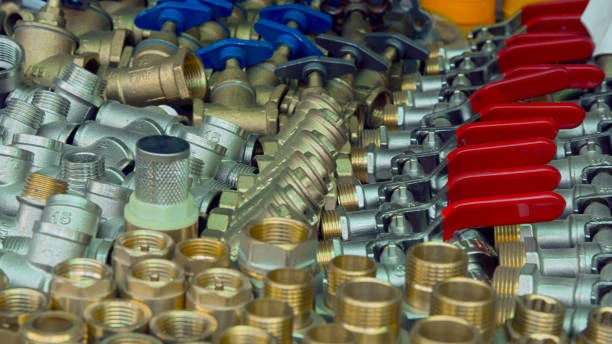

Copper fittings are essential components in plumbing and electrical systems, known for their durability, corrosion resistance, and versatility. Commonly used in residential, commercial, and industrial applications, these fittings connect copper pipes and are crucial for maintaining the integrity of plumbing systems.

The Rise of India’s Copper Fittings Industry

Historically, India was one of the top producers and exporters of copper fittings, thanks to its rich copper resources and a robust manufacturing sector. Indian manufacturers catered to both domestic and international markets, leveraging cost-effective labor and production techniques.

However, several factors contributed to India’s recent shift from exporter to importer:

1. Increased Domestic Demand

India’s rapid urbanization and infrastructure development have led to a surge in domestic demand for copper fittings. As cities expand and new residential and commercial projects emerge, the need for high-quality plumbing and electrical systems has grown, putting pressure on local manufacturers.

2. Supply Chain Disruptions

The COVID-19 pandemic disrupted global supply chains, impacting the availability of raw materials. Indian manufacturers faced delays and increased costs, making it challenging to meet domestic demand while maintaining export levels.

3. Quality Concerns

In recent years, some Indian manufacturers struggled with quality control, leading to a decline in the reputation of Indian copper fittings in international markets. This deterioration made foreign buyers wary and turned their focus to more reliable suppliers, further pushing India into the role of an importer.

4. Government Policies and Import Duties

Changing government policies, including increased import duties on certain raw materials, affected the manufacturing costs in India. As production costs rose, many manufacturers found it more economically viable to import finished copper fittings rather than produce them locally.

The Emergence of Pakistan as a copper fittings Supplier

As India transitioned into a net importer, Pakistan seized the opportunity to enhance its position in the copper fittings market. The country has a rich resource base and an emerging manufacturing sector capable of meeting the rising demand in India and other markets.

1. Competitive Pricing

Pakistani manufacturers have been able to offer competitive pricing on copper fittings due to lower production costs. This advantage allows them to capture a significant share of the market, especially in regions where cost sensitivity is paramount.

2. Quality Improvements

Pakistan has invested in improving the quality of its copper fittings production, adopting modern manufacturing techniques and quality control measures. This has made their products more appealing to Indian importers looking for reliable alternatives.

3. Geographic Proximity

Pakistan’s geographical proximity to India reduces shipping times and costs. This logistical advantage enables quicker deliveries, making Pakistani copper fitting more attractive to Indian buyers who require timely access to materials.

4. Strategic Trade Agreements

Pakistan has also sought to strengthen trade relationships with India and other countries, facilitating smoother trade in copper fitting. This strategic approach allows Pakistani manufacturers to navigate the complexities of international trade more effectively.

The Impact on the copper fittings Indian Market

The shift from exporter to importer has significant implications for the Indian market. While it may present challenges, it also opens opportunities for growth and adaptation:

1. Increased Prices for copper fittings Consumers

With India relying on imports, the cost of copper fittings may rise, impacting construction and plumbing costs. This increase can lead to higher prices for consumers and may slow down infrastructure projects.

2. Focus on Quality Control

As Indian manufacturers face competition from imports, there is a renewed focus on improving quality control and production processes. This could lead to advancements in manufacturing standards and product quality in the long term.

3. Potential for Local Innovation

The challenge of competing with imported products may spur innovation among Indian manufacturers. Emphasizing research and development can lead to new product offerings and improved technologies in the plumbing and electrical sectors.

4. Market Realignment

The shift may prompt a realignment in the copper fitting market, with manufacturers exploring new strategies to reclaim their position. This could involve diversifying product lines, enhancing customer service, or investing in sustainable practices.

The Future of the Copper Fittings Market

The global copper fitting market is likely to continue evolving, influenced by various factors:

1. Sustainability Initiatives

As environmental concerns grow, manufacturers may shift towards sustainable practices in production. The use of recycled copper and eco-friendly manufacturing processes could become more prevalent.

2. Technological Advancements

The incorporation of technology in manufacturing and logistics could improve efficiency and quality. Innovations such as automation and data analytics may play a crucial role in shaping the future of the industry.

3. Market Expansion

Both India and Pakistan are well-positioned to expand their markets. India, with its vast population and infrastructure needs, and Pakistan, with its emerging manufacturing capabilities, could establish themselves as key players in the copper fittings industry.

copper fittings Conclusion

India’s transition from a copper fittings exporter to an importer in just three years highlights the complexities of the global market and the impact of various external factors. As Pakistan steps in to fill the gap, both countries face new challenges and opportunities. The copper fitting industry will need to adapt to changing demands, focus on quality, and embrace innovation to thrive in the future.

FAQs

- What are copper fitting used for?

- Copper fitting are used in plumbing and electrical systems to connect pipes and ensure secure and leak-free connections.

- Why has India shifted from exporting to importing copper fitting?

- Increased domestic demand, supply chain disruptions, quality concerns, and changing government policies have contributed to this shift.

- How is Pakistan benefiting from India’s import of copper fitting?

- Pakistan is capitalizing on competitive pricing, improved quality, geographic proximity, and strategic trade agreements to enhance its market presence.

- What impact does the import of copper fitting have on Indian consumers?

- Import reliance may lead to increased prices for copper fitting, affecting construction costs and consumer pricing.

- What are the future trends in the copper fitting market?

- Sustainability initiatives, technological advancements, and market expansion are likely to shape the future of the copper fitting industry.