Brass push-fittings have revolutionized the plumbing industry, offering a faster, more efficient way to connect pipes without the need for soldering, crimping, or using specialized tools. These fittings provide a reliable, leak-free connection for various applications, making them an attractive option for both professional plumbers and DIY enthusiasts. Brass push-fittings are particularly valuable for installers, as they simplify the installation process, save time, and reduce the complexity of the job. In this article, we’ll explore how brass push-fittings can make jobs easier for installers and why they are becoming an essential component in modern plumbing systems.

What Are Brass Push-Fittings?

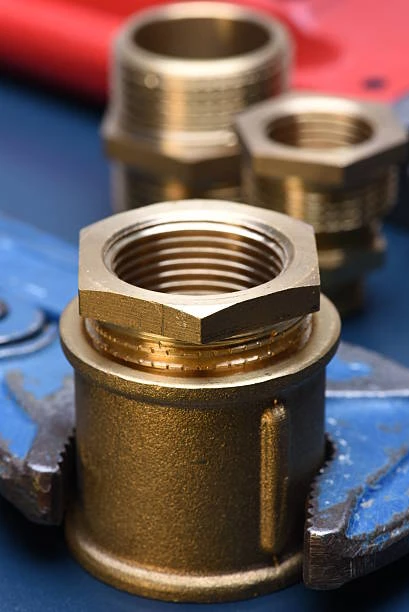

Brass push-fittings are plumbing components made from durable brass material, designed to create a secure connection between pipes by simply pushing them into place. The innovative design eliminates the need for traditional joining methods like soldering, gluing, or threading. Inside the fitting, an O-ring and stainless steel teeth securely grip the pipe, forming a watertight seal. Brass push-fittings are compatible with various pipe materials, including copper, PEX, and CPVC, making them a versatile solution for different plumbing systems.

These fittings are widely us in residential, commercial, and industrial plumbing applications, offering reliable performance while simplifying the installation process. The high-quality brass material ensures that these fittings are corrosion-resistant, durable, and capable of handling high pressures, making them suitable for both hot and cold water systems.

Faster Installation Time

One of the most significant advantages of using brass push-fittings is the speed of installation. Traditional plumbing methods, such as soldering or crimping, can be time-consuming and require specialized tools and skills. With brass push-fittings, installers can connect pipes in seconds by simply pushing the pipe into the fitting until it locks into place. This quick installation process significantly reduces the time spent on plumbing projects, allowing installers to complete jobs more efficiently.

For larger projects where multiple connections are need, the time savings can be substantial. In some cases, the use of brass push-fittings can cut installation time by more than half, which is particularly beneficial in situations where deadlines are tight, such as new construction or emergency repairs.

Elimination of Specialized Tools

Brass push-fittings offer another major benefit for installers by eliminating the need for specialized tools. Traditional plumbing techniques often require a range of tools, including soldering equipment, crimping tools, pipe wrenches, and heat sources. These tools can be expensive to purchase and maintain, and they add complexity to the installation process.

With brass push-fittings, the only tool typically requir is a pipe cutter to ensure that the pipe is cut cleanly and to the correct length. After cutting the pipe, installers can simply push the pipe into the fitting without needing additional equipment. This reduces the overall cost of tools and allows for a more straightforward, hassle-free installation process, particularly for those who may not have access to a full set of plumbing tools.

Versatility with Different Pipe Types

One of the most appealing aspects of brass push-fittings is their versatility. These fittings are compatible with a wide range of pipe materials, including copper, PEX, and CPVC. This versatility means that installers can use the same type of fitting for various pipe systems, simplifying inventory management and reducing the need for multiple types of fittings for different materials.

For example, a plumber working on a mixed-material system can use brass push-fittings to connect copper pipes to PEX without needing additional adapters or tools. This flexibility makes brass push-fittings an ideal choice for both new installations and retrofit projects, where different pipe materials may be present.

Reliable, Leak-Free Connections

Brass push-fittings are design to provide reliable, long-lasting, and leak-free connections. The fittings use a combination of an O-ring seal and stainless steel gripping teeth to create a secure connection. When the pipe is push into the fitting, the teeth grip the pipe while the O-ring forms a watertight seal, ensuring a durable connection.

This reliability is especially important in high-pressure systems, where even small leaks can cause significant problems over time. Brass push-fittings have been rigorously test and are proven to hold up under high-pressure conditions, making them a trusted choice for water supply lines, heating systems, and other demanding applications.

Additionally, these fittings are removable and reusable, which means that if adjustments are need, the fittings can be disconnected using a simple release tool and reinstalled without damaging the pipe or the fitting. This flexibility makes it easier for installers to make corrections or modifications without needing to replace the entire fitting.

Reducing Risk of Installation Errors

Traditional plumbing methods like soldering or crimping can be prone to errors if not performed correctly. A poorly soldered joint can lead to leaks, while incorrect crimping can result in weak connections that fail over time. Brass push-fittings reduce the likelihood of installation errors, as the connection process is straightforward and doesn’t require advanced skills or techniques.

Installers simply need to ensure that the pipe is cut squarely and inserted fully into the fitting. Once the pipe is in place, the fitting automatically creates a secure connection, reducing the risk of user error. This makes brass push-fittings an excellent choice for novice plumbers, DIYers, or professionals working in high-pressure environments where mistakes could be costly.

Ideal for Tight Spaces

In many plumbing installations, space can be limited, making it difficult to use traditional tools and techniques. Soldering or crimping in tight spaces can be challenging, especially when access is restrict. Brass push-fitting solve this problem by allowing installers to make quick connections in confined areas without the need for bulky equipment or open flames.

Since no heat is required, brass push-fitting are also safer to use in tight spaces, particularly when working near flammable materials or in areas with poor ventilation. This makes them an ideal solution for working in basements, crawl spaces, or behind walls where traditional plumbing methods may be impractical.

Cost-Effective Solution

Although brass push-fitting may have a higher upfront cost compared to some traditional fitting, the overall cost savings they provide can be significant. By reducing installation time, eliminating the need for specialized tools, and minimizing the risk of errors, brass push-fitting help lower labor costs and reduce the potential for costly repairs or rework.

Additionally, because these fittings are removable and reusable, they offer long-term savings by allowing installers to make adjustments or repairs without having to replace the entire fitting. This makes them a cost-effective solution for both residential and commercial plumbing projects.

Conclusion

Brass push-fittings offer a range of benefits that make them an excellent choice for installers looking to streamline their work and improve efficiency. With their ease of installation, versatility, and reliable performance, these fittings provide a fast, safe, and cost-effective solution for connecting pipes in various plumbing systems. Whether working on new installations, repairs, or retrofits, brass push-fitting can help installers save time, reduce the need for specialized tools, and create leak-free, long-lasting connections.

FAQ

1. What are brass push-fitting used for?

Brass push-fitting are us to quickly and securely connect pipes in plumbing systems without the need for soldering, crimping, or threading. They are commonly us in water supply lines, heating systems, and other plumbing applications.

2. Are brass push-fitting compatible with different pipe materials?

Yes, brass push-fitting are compatible with various pipe materials, including copper, PEX, and CPVC, making them versatile for different plumbing systems.

3. Can brass push-fitting be reus?

Yes, brass push-fitting are design to be removable and reusable. They can be disconnected using a release tool and reinstalled without damaging the pipe or fitting.

4. How do brass push-fitting create a leak-free connection?

Brass push-fitting use an O-ring seal and stainless steel gripping teeth to create a secure, leak-free connection when the pipe is push into the fitting.

5. Do brass push-fitting require any special tools?

No, brass push-fitting do not require any special tools for installation. A simple pipe cutter is typically the only tool need to prepare the pipe for connection.