Copper water pipe fittings are renowned for their durability and reliability in plumbing systems. However, leaks can still occur, leaving homeowners frustrated and seeking solutions. Understanding why these leaks happen, even when no obvious cause is apparent, and knowing how to address them is crucial for maintaining an efficient plumbing system. This article will explore the nature of leaks in copper water pipe fittings, common scenarios leading to leaks, and best practices for prevention and repair.

Understanding Copper Water Pipe Fittings

What Are Copper Water Pipe Fittings?

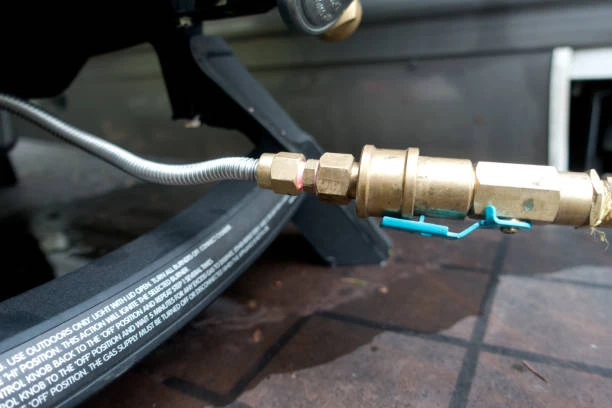

Copper water pipe fittings are essential components in plumbing systems, connecting various segments of copper piping. These fittings come in numerous shapes and sizes, including elbows, tees, and couplings, each serving specific purposes in the plumbing network.

Advantages of Copper Fittings

- Durability: Copper fittings are resistant to corrosion, ensuring a long lifespan when properly installed and maintained.

- Antimicrobial Properties: Copper’s natural ability to inhibit bacterial growth makes it a safe choice for water supply lines.

- Recyclability: Copper is a sustainable material that can be recycled, contributing to environmentally friendly practices.

Causes of Leaks in Copper Water Pipe Fittings

Common Scenarios Leading to Leaks

- Improper Installation: One of the primary causes of leaks is improper installation. Fittings that are not adequately soldered or fitted can create gaps that lead to water leaks.

- Thermal Expansion and Contraction: Copper expands and contracts with temperature changes. This natural movement can stress joints and fittings, leading to potential leaks over time.

- Corrosion: Although copper is resistant to corrosion, it can still occur, especially in aggressive water conditions. This can weaken fittings and cause leaks.

- Water Pressure Fluctuations: High water pressure can strain fittings, leading to leaks. Sudden pressure changes can exacerbate this issue.

- Age and Wear: Over time, even the most durable materials can deteriorate. Old fittings may become weak and develop leaks due to general wear and tear.

Identifying Leaks

Detecting leaks early can prevent significant damage to your plumbing system. Signs of leaks in copper fittings include:

- Water Stains: Discoloration on walls, ceilings, or floors can indicate a hidden leak.

- Mold or Mildew: Excess moisture often leads to mold growth, which can signal a plumbing issue.

- Decreased Water Pressure: A drop in water pressure may indicate a leak in the system.

- Puddles or Wet Spots: Visible water accumulation around fittings is a clear sign of a leak.

Remedies for Copper Water Pipe Fitting Leaks

Temporary Fixes

If you discover a leak, taking immediate action can mitigate damage. Here are some temporary remedies:

- Pipe Clamp: A pipe clamp can provide a quick fix by compressing the area around the leak. This method is only temporary and should not replace a permanent solution.

- Epoxy Putty: Using epoxy putty can seal minor leaks. Clean the area around the leak, apply the putty, and allow it to cure as per the manufacturer’s instructions.

- Rubber Patch: A piece of rubber secured with a hose clamp can temporarily stop leaks. This method can help until a more permanent solution is applied.

Permanent Solutions

To ensure long-lasting results, consider these permanent remedies:

- Soldering: For leaks at solder joints, re-soldering the fitting may provide a permanent fix. This requires heating the joint and applying new solder.

- Replacement: If a fitting is severely corroded or damaged, replacing it may be the best option. Cut out the faulty section and install a new fitting.

- Professional Help: When in doubt, consult a licensed plumber. They can assess the situation and implement the most effective solution.

Preventing Future Leaks

Best Practices

To reduce the likelihood of leaks in copper water pipe fittings, consider these preventive measures:

- Proper Installation: Always ensure fittings are correctly soldered and fitted. Following manufacturer guidelines during installation can prevent future issues.

- Monitor Water Pressure: Regularly check your water pressure to ensure it stays within the recommended range. Installing a pressure regulator can help manage fluctuations.

- Regular Inspections: Conduct routine checks of your plumbing system to identify signs of wear or leaks before they become serious problems.

- Temperature Management: Insulate pipes to minimize temperature fluctuations, especially in areas prone to extreme temperatures.

- Water Quality Testing: If your water is highly acidic or contains high levels of minerals, consider water treatment options to reduce corrosion risk.

Conclusion

While copper water pipe fittings are generally reliable and durable, leaks can still occur due to various factors, including improper installation, thermal expansion, and corrosion. Understanding these causes, identifying leaks promptly, and implementing effective remedies are crucial for maintaining your plumbing system. By following best practices for installation and maintenance, you can significantly reduce the risk of leaks and ensure a long-lasting plumbing solution.

Frequently Asked Questions (FAQs)

- What are the most common causes of leaks in copper water pipe fittings?

Common causes include improper installation, thermal expansion, corrosion, high water pressure, and general wear and tear. - How can I identify a leak in my copper fittings?

Look for water stains, mold or mildew, decreased water pressure, or puddles around the fittings. - What are some temporary fixes for leaks?

Temporary fixes include using a pipe clamp, epoxy putty, or a rubber patch secured with a hose clamp. - When should I consider replacing a copper fitting?

If a fitting is severely corroded or damaged, replacement may be the best option for a permanent fix. - How can I prevent leaks in the future?

Proper installation, monitoring water pressure, regular inspections, managing temperature, and testing water quality can help prevent leaks.