Introduction to Press Fitting Systems

In modern plumbing and HVAC installations, press fitting ASTM F1974 systems have become increasingly popular due to their speed, reliability, and ease of use. However, understanding the various press fitting profiles and the tooling required for proper installation can be confusing, especially for those new to the technology. This guide will break down the different types of press fitting profiles, the tools you need, and how they work together to simplify your plumbing projects.

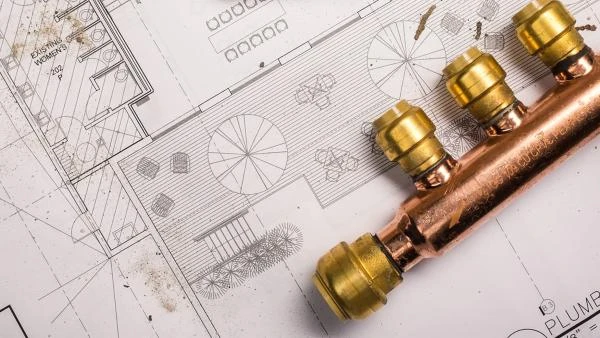

What Are Press Fittings?

Press fittings are a type of connection system used to join pipes without the need for soldering, welding, or threading. Instead, a press tool is used to crimp or “press” the fitting onto the pipe, creating a secure, leak-proof connection. These fittings are used in various applications, including water supply, gas lines, and heating systems.

Common Press Fitting Profiles

Different press fitting profiles are available, each with its own design and application. Understanding the most common profiles will help you select the right one for your project:

1. M Profile

The M profile is widely used in both commercial and residential plumbing systems. It has a rounded, wide crimping area that provides a strong, leak-proof seal, making it ideal for high-pressure applications.

2. V Profile

The V profile is another popular choice, especially in industrial settings. It has a narrow, pointed crimping area that delivers a tighter seal, often used in gas and oil systems.

3. B Profile

Primarily used in Europe, the B profile is known for its versatility and reliability in potable water systems. Its design allows for a more flexible crimp, suitable for both high- and low-pressure applications.

4. TH Profile

The TH profile is used mainly in heating and cooling systems. Its unique crimping design allows it to withstand temperature fluctuations, making it ideal for installations involving hot water and steam.

5. U Profile

The U profile is commonly used in multilayer and PEX pipe systems. Its rounded crimp provides a secure seal in low-pressure applications, typically used in residential water supply and heating.

Understanding Press Tooling

Press tooling is an essential component of the press fitting system, and choosing the right tool is critical for a successful installation. Here are the basic types of press tools and their features:

1. Manual Press Tools

Manual press tools are by hand and are suitable for smaller projects or jobs where power sources are limited. They are lightweight and portable but may require more physical effort compared to powered tools.

2. Battery-Powered Press Tools

Battery-powered press tools are ideal for larger jobs or contractors who need to work quickly. These tools are highly portable and offer the convenience of cordless operation, allowing users to make multiple presses without fatigue.

3. Hydraulic Press Tools

Hydraulic press tools are for heavy-duty applications. They offer more power and can press larger pipe sizes, making them ideal for industrial or commercial installations. However, they are typically more expensive and bulkier than other press tools.

Matching the Right Tool to the Right Profile

Not all press tools work with every press fitting profile, so it’s essential to match the tool with the correct profile for your fittings. Many press tools come with interchangeable jaws or attachments to accommodate different profiles, but always check compatibility before starting your project.

1. Jaws and Attachments

Most press tools come with a variety of jaw sizes and shapes, designed to fit specific profiles and pipe diameters. Ensure that the jaws you are using match both the pipe size and the profile of the fitting to guarantee a proper seal.

2. Calibration

Press tools, particularly battery-powered and hydraulic models, may require regular calibration to ensure they deliver the correct amount of force. Using a poorly calibrated tool can lead to weak or inconsistent seals, increasing the risk of leaks.

3. Maintenance

Press tools need regular maintenance to perform at their best. Keep them clean and store them properly to prevent wear and tear. For power tools, regularly check the battery charge and hydraulic fluid levels.

How to Avoid Common Press Fitting Mistakes

While press fittings and tools are to make plumbing jobs easier, mistakes can still happen. Here are some common pitfalls and how to avoid them:

1. Choosing the Wrong Profile

Using the wrong profile for the application can result in leaks or a poor fit. Always consult manufacturer guidelines to ensure you’re using the right profile for the job.

2. Incomplete Press

An incomplete press can occur if the tool isn’t fully or if the jaw slips during pressing. Always double-check your press to ensure a complete and secure connection.

3. Neglecting Pipe Preparation

Before pressing, always ensure the pipe cut straight, and clean. Skipping this step can compromise the seal and lead to leaks.

4. Incorrect Tool Size

Using the wrong tool size for the fitting can result in an improper press, which weakens the connection. Make sure to use the right-sized jaws for the fitting and pipe diameter.

Conclusion

Understanding press fitting profiles and press tooling is crucial for successful plumbing installations. By familiarizing yourself with the different profiles—M, V, B, TH, and U—and choosing the right press tool for your job, you can ensure reliable, leak-free connections every time. Whether you’re working on residential plumbing, commercial HVAC systems, or industrial gas lines, following the correct processes and avoiding common mistakes will simplify the installation and save time.