Introduction

Threaded brass fittings are essential components in various plumbing and piping applications, known for their durability and reliable performance. These fittings are designed to connect pipes and equipment using male and female threads, creating secure, leak-free joints. This guide covers the features, benefits, types, and installation tips for threaded brass fittings.

Key Features of Threaded Brass Fittings

- Durable Brass Construction

Made from high-quality brass, these fittings resist corrosion and wear, ensuring a long lifespan even in challenging environments. - Variety of Thread Types

Available in various thread designs, including NPT (National Pipe Thread) and BSP (British Standard Pipe), making them suitable for different plumbing standards. - Ease of Installation

Threaded fittings can be easily connected and disconnected, allowing for straightforward installation and maintenance.

Benefits of Using Threaded Brass Fittings

- Reliable Sealing: The threaded design ensures a tight seal, minimizing the risk of leaks and maintaining system efficiency.

- Versatile Applications: Suitable for both residential and industrial uses, including water, gas, and air systems.

- High Strength: Brass fittings provide excellent strength and can withstand high pressures, making them ideal for demanding applications.

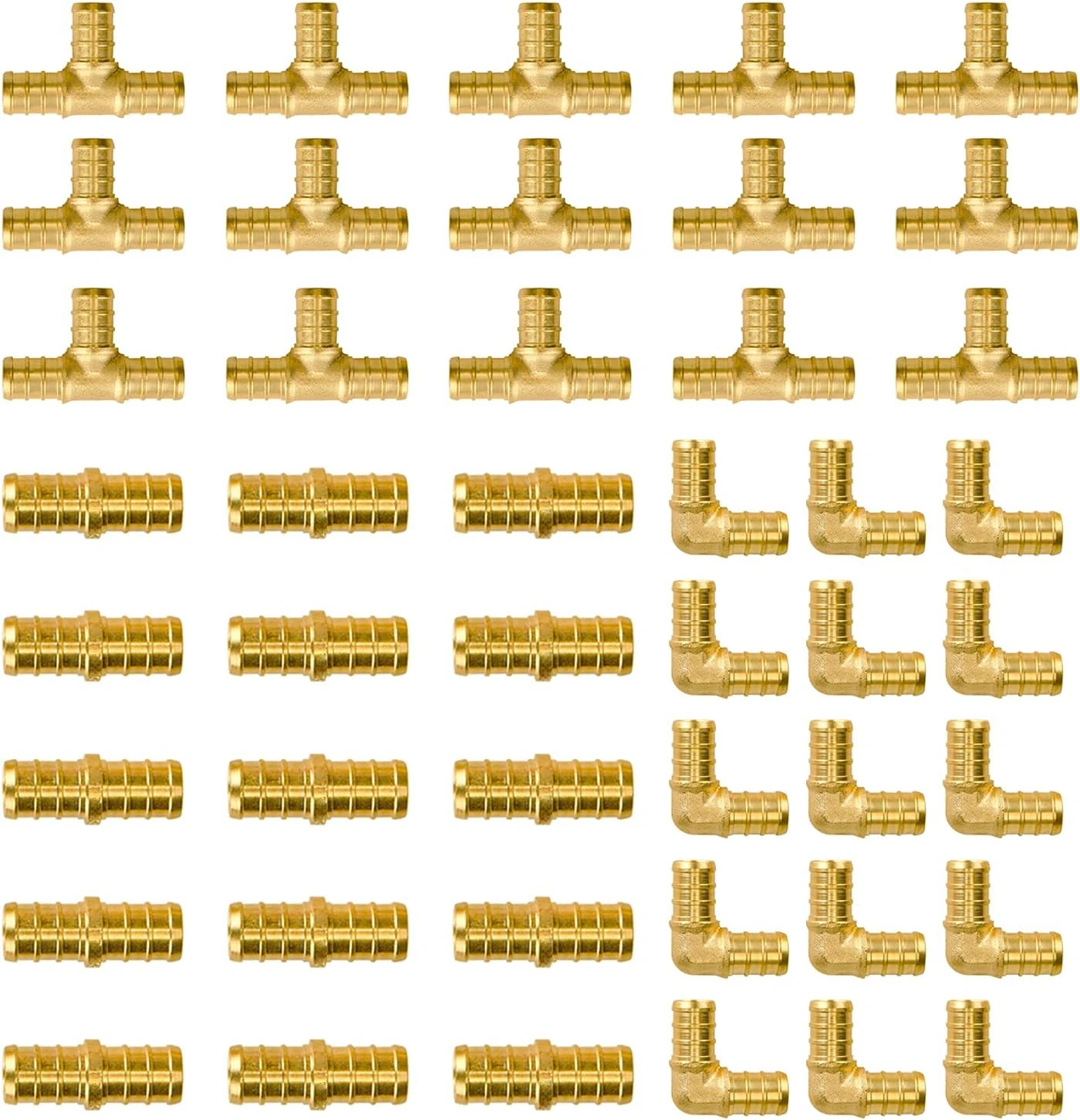

Types of Threaded Brass Fittings

- Elbows: Used to change the direction of piping, typically at a 90-degree angle.

- Tees: Allow branching off to additional pipes, facilitating multiple lines from a single source.

- Couplings: Connect two sections of pipe together, ensuring a secure joint.

- Adapters: Enable connections between different sizes or types of pipes, enhancing system flexibility.

- Plugs and Caps: Used to seal the ends of pipes or fittings, providing a secure closure.

Installation Tips

- Choose the Right Size: Ensure the fitting matches the diameter and thread type of your pipes.

- Use Thread Sealant: Apply plumber’s tape or thread sealant to the threads to prevent leaks.

- Hand Tighten First: Start by hand-tightening the fitting to ensure proper alignment, then use a wrench for additional tightening.

- Avoid Over-tightening: Over-tightening can damage the fitting or pipe threads, so tighten only until snug.

- Check for Leaks: Once installed, turn on the water or gas supply and check for leaks around the connections.

Conclusion

Threaded that are a reliable and versatile solution for connecting pipes in various plumbing applications. Their durability and ease of installation make them a preferred choice for both professionals and DIY enthusiasts.

FAQs

1. What are the advantages of using threaded brass fittings?

They provide a secure, leak-free connection, are easy to install, and are suitable for a variety of applications.

2. What types of threads do these fittings have?

Common types include NPT (National Pipe Thread) and BSP (British Standard Pipe), which cater to different plumbing standards.

3. Can threaded brass fittings be used for gas applications?

Yes, many threaded are designed for gas applications, but always check for specific compatibility.

4. How do I maintain threaded brass fittings?

Regularly inspect for leaks and ensure that connections remain tight to prevent any issues.

5. Are there different sizes available?

Yes, threaded it come in various sizes to accommodate different pipe diameters and applications.

What is the company’s goal in the plumbing industry?

What is the Company’s Goal in the Plumbing Industry?

The company is committed to setting a new standard in the realm of decorative plumbing solutions. By focusing on innovation and quality, their aim is to become the industry leader in manufacturing unique and high-quality plumbing fixtures. Whether it’s faucets, showerheads, or accessories, they strive to offer products that combine aesthetic appeal with functionality, surpassing the competition in design and performance.

Their ambition doesn’t stop at product excellence. They also aim to enhance customer experiences, ensuring that every interaction with their brand is seamless and satisfying. Through continuous improvement and dedication to craftsmanship, they aspire to not just meet but exceed expectations, positioning themselves as the top choice for discerning customers seeking distinctive plumbing enhancements.