Advanced Drainage Systems (ADS) recently launched a new plastic pipe plant in Clifford, creating significant industry buzz. This facility enhances ADS’s manufacturing capabilities and strengthens its position in the drainage solutions market. Below, we explore how this new development impacts the industry and the benefits it offers.

Plastic Pipe Plant in Clifford Expands ADS’s Production Capacity

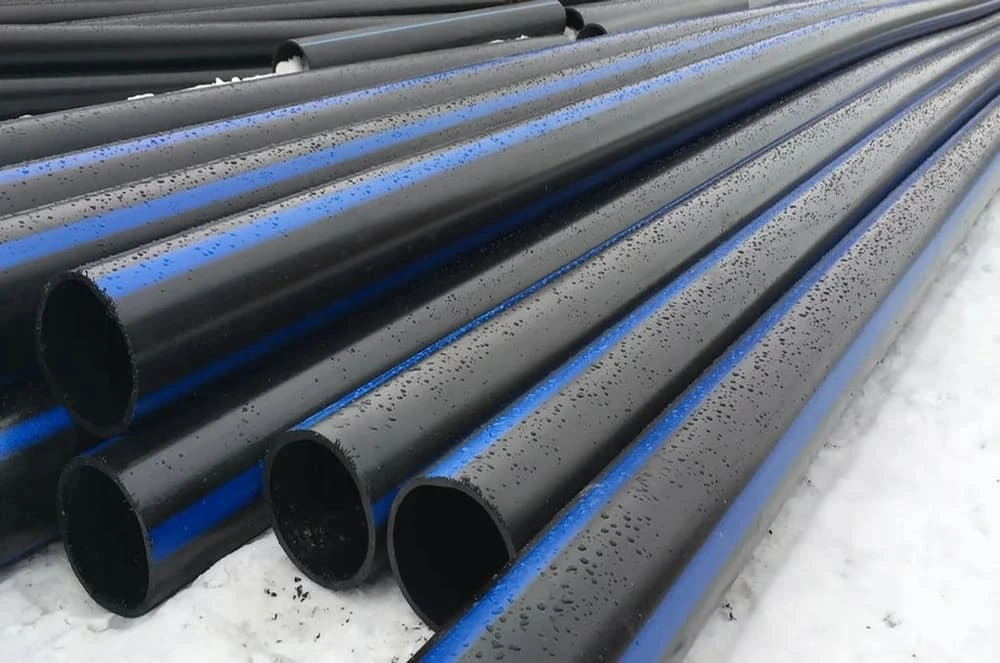

The new plastic pipe plant boosts ADS’s ability to meet rising demand for quality drainage solutions. Clifford, with its strategic location, provides easy access to raw materials and distribution channels. This plant focuses on producing high-performance plastic pipes that cater to various sectors, including agriculture, construction, and infrastructure.

Innovative Technologies at the Plastic Pipe Plant

ADS integrates state-of-the-art machinery and technology in its Clifford plastic pipe plant. These advanced systems ensure precision and efficiency in pipe production. The plant also prioritizes sustainable manufacturing processes, reducing waste and energy consumption. By leveraging cutting-edge technology, ADS reinforces its commitment to delivering durable and eco-friendly plastic pipes.

Economic Benefits of the Clifford Plastic Pipe Plant

The establishment of this plastic pipe plant contributes to the local economy in Clifford. It creates numerous job opportunities, from plant operations to logistics and administration. Additionally, the increased production capacity supports regional infrastructure projects, fostering economic growth in the surrounding areas.

How the Plastic Pipe Plant Enhances Product Quality

The Clifford plant enables ADS to maintain strict quality control standards for its plastic pipes. Each product undergoes rigorous testing to ensure durability and performance. The plant’s advanced systems minimize defects, resulting in reliable and long-lasting plastic pipes for various applications.

Environmental Impact

The new plastic pipe plant in Clifford follows environmentally conscious practices to reduce its carbon footprint. ADS uses recyclable materials and energy-efficient equipment to minimize waste. The company also implements water-saving technologies to align with global sustainability goals.

Key Applications and Benefits

Plastic pipes manufactured in Clifford serve multiple industries due to their versatility and durability. In agriculture, they ensure efficient water management, improving crop yield. In construction, plastic pipes provide robust drainage systems that last for decades. Additionally, infrastructure projects benefit from lightweight yet strong plastic pipes, which are easy to install and maintain.

ADS Leads the Plastic Pipe Market with the Clifford Plant

With the establishment of this new plant in Clifford, ADS reinforces its position as a leader in the highly competitive plastic pipe industry. This strategic investment not only expands its production capabilities but also demonstrates the company’s commitment to innovation, efficiency, and customer satisfaction. The Clifford facility is strategically located to optimize logistics, allowing ADS to deliver products more quickly to its customers while significantly reducing transportation costs. This strategic advantage ensures that ADS can remain agile in meeting the growing demand for high-quality plastic pipes across various industries.

The plant also serves as a testament to ADS’s forward-thinking approach to manufacturing. Beyond production, the company places a strong emphasis on research and development (R&D) at the Clifford facility. By integrating cutting-edge technologies and conducting extensive product testing, ADS is able to innovate and introduce advanced plastic pipe solutions that address modern challenges. These challenges include increasing sustainability demands, the need for longer-lasting infrastructure, and the push for more cost-effective materials.

Moreover, ADS’s focus on R&D is driven by its desire to meet evolving customer needs. Whether it’s improving durability, enhancing environmental performance, or customizing designs for specific projects, the company ensures that its plastic pipes remain at the forefront of the industry. The Clifford plant is not just a manufacturing hub but also a center for progress, where ADS continues to push the boundaries of what plastic pipe technology can achieve. Through this facility, ADS solidifies its leadership and sets new standards for quality, sustainability, and innovation in the plastic pipe market.

Future Prospects

The plastic pipe market continues to grow due to increasing infrastructure and agricultural investments. The Clifford plant positions ADS to capitalize on these trends and remain a key player in the industry. As demand for sustainable and high-quality plastic pipes rises, this plant ensures ADS stays ahead of the competition.

Why ADS Chose Clifford for Its Plastic Pipe Plant

Clifford offers excellent infrastructure and a skilled workforce, making it an ideal location for the new plastic pipe plant. The town’s proximity to major markets ensures efficient distribution of ADS products. Clifford’s support for industrial development further influenced ADS’s decision to invest in this location.

Customer-Centric Approach

The Clifford plant reflects ADS’s dedication to meeting customer needs. The facility’s increased capacity ensures timely delivery of orders, even during peak demand periods. ADS also provides customization options for plastic pipes to suit specific project requirements.

FAQs

1. What products does the Clifford plastic pipe plant manufacture?

The plant produces high-performance plastic pipes for agriculture, construction, and infrastructure projects.

2. How does the plant contribute to sustainability?

The facility uses recyclable materials and energy-efficient equipment to minimize its environmental impact.

3. What industries benefit from ADS plastic pipes?

ADS plastic pipes serve agriculture, construction, and infrastructure sectors with reliable and durable solutions.

4. How does the Clifford plant impact the local economy?

The plant creates jobs and supports regional economic growth through increased production capacity.

5. Why is Clifford a strategic location for this plant?

Clifford offers excellent infrastructure, skilled labor, and proximity to key markets, ensuring efficient operations.