Introduction

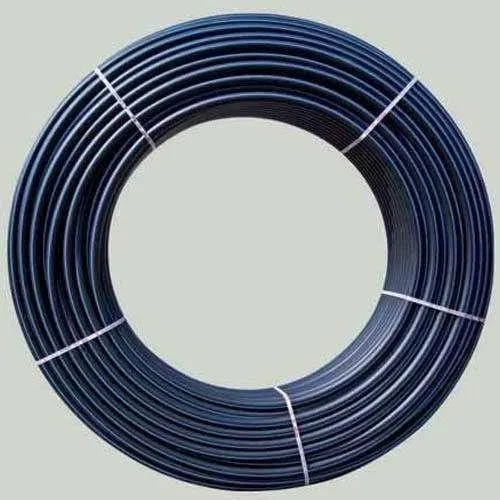

Polyethylene PE pipe have gained significant traction across various industries due to their numerous advantages. As infrastructure demands evolve, the use of PE pipe in water supply, drainage, and industrial applications has become increasingly popular. In this article, we’ll explore the many benefits of PE pipes and why they might be the perfect choice for your needs.

Durability and Longevity

Resistance to Corrosion

One of the standout features of PE pipes is their excellent resistance to corrosion. Unlike metal pipes, which can rust and degrade over time, PE pipes remain unaffected by harsh environmental conditions. This durability ensures they can withstand a wide range of substances, including acidic and alkaline materials.

Longevity Compared to Traditional Materials

PE pipes can last for decades, often exceeding 50 years of service life. This longevity makes them a reliable choice for long-term projects, reducing the need for frequent replacements.

Flexibility and Lightweight

Easy to Transport and Install

PE pipes are significantly lighter than traditional piping materials, such as steel or concrete. This lightweight nature makes them easier to handle, transport, and install, resulting in lower labor costs and quicker project completion.

Adaptability in Various Environments

The flexibility of PE pipes allows them to bend around obstacles and adapt to uneven terrain. This characteristic makes them ideal for installation in challenging conditions, such as rocky or hilly landscapes.

Cost-Effectiveness

Initial Investment vs. Long-Term Savings

While the initial cost of PE pipes might be comparable to other materials, their long-term savings are substantial. With lower installation costs, reduced maintenance, and fewer replacements needed over time, PE pipes can lead to significant savings.

Reduced Maintenance Costs

Due to their durability and resistance to wear, PE pipes require less maintenance than traditional piping materials. This means less money spent on repairs and upkeep, making them a financially savvy choice.

Chemical Resistance

Compatibility with Various Substances

PE pipes are resistant to a wide array of chemicals, making them suitable for transporting everything from potable water to harsh industrial chemicals. This versatility allows them to be used in diverse applications without compromising safety.

Safe for Transporting Chemicals

Their chemical resistance ensures that PE pipes won’t degrade or leach harmful substances into the transported materials, providing peace of mind in industrial settings.

Leak-Free Connections

Enhanced Sealing Technology

Modern PE piping systems often incorporate advanced sealing technologies that significantly reduce the risk of leaks. These innovations create secure joints, ensuring water and materials are safely contained.

Reduced Risk of Leaks and Failures

With fewer potential failure points, PE pipes contribute to overall system reliability, decreasing the likelihood of costly leaks and the associated environmental impacts.

Environmental Benefits

Sustainable Manufacturing Processes

Many manufacturers of PE pipes prioritize sustainability in their production processes. The use of recycled materials and environmentally friendly practices contributes to a lower carbon footprint.

Recyclability of PE Pipes

PE pipes are 100% recyclable, allowing them to be reprocessed and reused at the end of their life cycle. This eco-friendly feature supports circular economy practices and reduces waste.

Versatile Applications

Use in Water Supply and Drainage

PE pipes are widely used in municipal water systems, irrigation, and drainage applications. Their durability and flexibility make them suitable for both urban and rural settings.

Industrial Applications and Beyond

From transporting chemicals to supporting industrial processes, PE pipes are versatile and can adapt to various sectors, including agriculture, construction, and energy.

Conclusion

In conclusion, the advantages of PE pipes are numerous, making them a top choice for a variety of applications. Their durability, flexibility, cost-effectiveness, and environmental benefits position them as a smart investment for any project. If you’re considering options for your piping needs, PE pipes are certainly worth a closer look.

FAQs

What is PE pipe made from?

PE pipes are made from high-density polyethylene, a strong and flexible plastic material.

How long do PE pipes last?

PE pipes can last for over 50 years with proper installation and maintenance.

Are PE pipes suitable for high-temperature applications?

While PE pipes are resistant to many chemicals, they have limitations with high-temperature fluids. Always check specific guidelines.

Can PE pipes be recycled?

Yes, PE pipes are 100% recyclable, making them an environmentally friendly choice.

What are the common uses of PE pipes?

PE pipes are commonly used in water supply, irrigation, drainage, and various industrial applications.