When choosing between brass and stainless steel ball valves ASTM D2241, it’s essential to consider factors such as durability, cost, corrosion resistance, and the specific application in which the valve will be used. Both materials have their strengths and limitations, so the right choice depends on the environment and performance requirements. Here’s a detailed comparison to help you decide which is better for your needs:

1. Durability

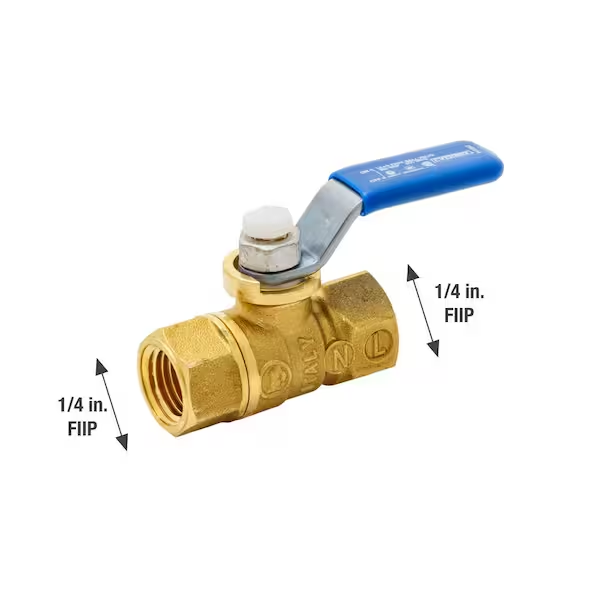

- Brass Ball Valves: Brass is a strong and durable material, able to withstand frequent use without cracking or degrading. It performs well in general applications, including plumbing, water systems, and gas flow control.

- Stainless Steel Ball Valves: Stainless steel is even more durable than brass, particularly in demanding industrial environments. It can handle high pressure and extreme temperatures better than brass, making it the preferred choice for heavy-duty applications. Winner: Stainless Steel for high-stress environments, but brass is durable enough for most standard applications.

2. Corrosion Resistance

- Brass Ball Valves: Brass offers excellent corrosion resistance in most water systems and air applications. However, it can corrode when exposed to certain chemicals, highly acidic or alkaline environments, or saltwater over long periods.

- Stainless Steel Ball Valves: Stainless steel, particularly grades like 304 or 316 stainless steel, offers superior corrosion resistance, especially in harsh environments, including exposure to chemicals, saltwater, and other corrosive substances. It resists rust and pitting better than brass. Winner: Stainless Steel for environments with corrosive elements, such as chemical plants or marine applications.

3. Temperature and Pressure Tolerance

- Brass Ball Valves: Brass performs well under moderate temperatures and pressures, making it suitable for most residential and commercial plumbing systems. It’s commonly used in water, gas, and air applications but may not handle extreme conditions as well.

- Stainless Steel Ball Valves: Stainless steel excels in extreme temperature and pressure environments. It can withstand much higher pressures and temperatures without deformation or failure, making it the ideal choice for high-pressure industrial systems or applications involving steam, oil, or chemicals. Winner: Stainless Steel for high-temperature and high-pressure applications.

4. Cost

- Brass Ball Valves: Brass valves are typically more affordable than stainless steel valves, making them a cost-effective choice for general-purpose applications. Their lower price point makes them ideal for residential use and non-critical systems.

- Stainless Steel Ball Valves: Stainless steel is more expensive due to its superior strength and corrosion resistance. The higher cost may be justified in environments where durability and resistance to harsh conditions are critical. Winner: Brass for cost-effective solutions, especially in less demanding environments.

5. Applications

- Brass Ball Valves: Ideal for residential plumbing, commercial water systems, heating, and air control. Brass is often used for general-purpose applications where moderate corrosion resistance and temperature tolerance are required.

- Stainless Steel Ball Valves: Best suited for industrial settings, such as chemical plants, oil and gas industries, marine applications, and high-temperature steam systems. Stainless steel is the go-to choice for environments with extreme conditions. Winner: Brass for residential and light commercial use; Stainless Steel for industrial or harsh environments.

6. Chemical Compatibility

- Brass Ball Valves: Brass may react with certain chemicals, such as ammonia or chlorine, causing degradation over time. It is not suitable for highly acidic or alkaline environments.

- Stainless Steel Ball Valves: Stainless steel is highly resistant to chemical reactions and is safe to use with a broad range of chemicals, acids, and bases. It’s ideal for chemical processing or applications where chemical exposure is a concern. Winner: Stainless Steel for chemical-heavy environments.

Conclusion: Which is Better?

- For residential and light commercial applications (plumbing, water systems, gas lines), brass ball valves are generally the better choice due to their cost-effectiveness and sufficient durability.

- For industrial applications or environments with extreme conditions (high temperatures, pressures, corrosive substances), stainless steel ball valves are superior, offering exceptional corrosion resistance and strength.

Ultimately, stainless steel is the better option for harsh environments and heavy-duty applications, while brass is more affordable and suitable for everyday use in standard conditions.