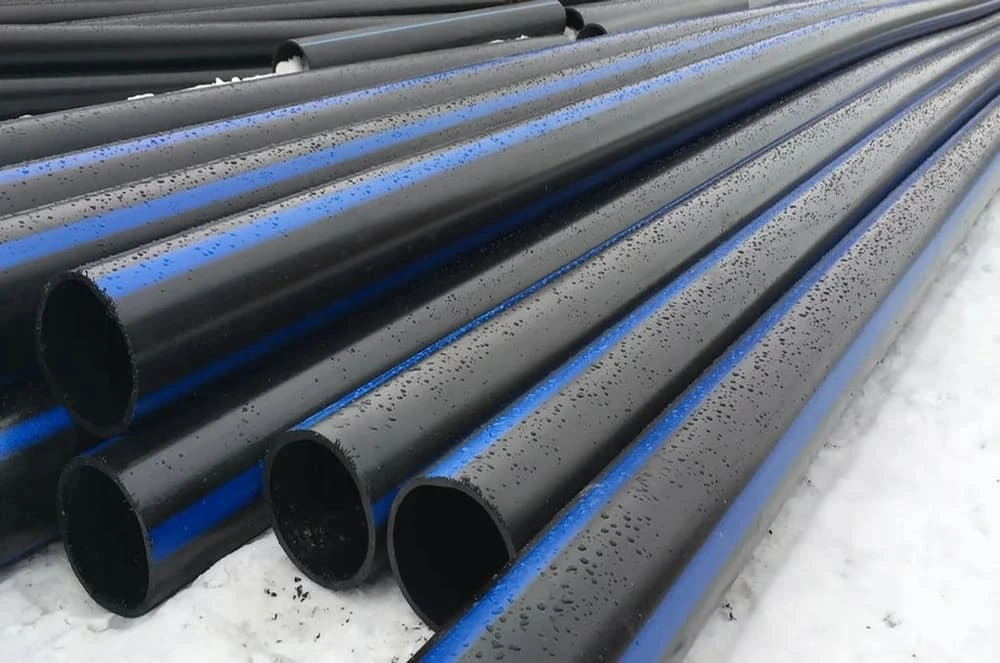

The Alexander First Nation in Canada has made a significant stride toward economic self-sufficiency with the launch of its new HDPE pipes plant. This facility will support both local infrastructure needs and contribute to the region’s growing economy. HDPE (High-Density Polyethylene) pipes are an essential component for modern infrastructure, offering durability and resistance to corrosion. The community’s venture into this industry positions it to meet the increasing demand for reliable, long-lasting pipe solutions in various sectors, including water, sewage, and oil & gas.

The Significance of the HDPE Pipes Plant for Alexander First Nation

The opening of the HDPE pipes plant in Alexander First Nation represents a milestone in economic development for the community. By entering the industrial manufacturing sector, the First Nation seeks to reduce dependency on external suppliers and create local jobs. The HDPE pipes produced at this plant will provide crucial infrastructure solutions for not just the local area but also for neighboring communities and industries.

Alexander First Nation’s decision to invest in this facility highlights its focus on sustainability and self-reliance. HDPE pipes are known for their longevity and minimal environmental impact, aligning with the First Nation’s commitment to ecological responsibility.

What Are HDPE Pipes and Why Are They Important?

HDPE stands for High-Density Polyethylene, a durable, flexible plastic material commonly used in piping systems. HDPE pipes are favored for their resistance to chemicals, UV radiation, and physical wear. They are ideal for water distribution systems, sewage lines, and even for use in the oil and gas industry. Their light weight, ease of installation, and cost-effectiveness make them a top choice for many infrastructure projects worldwide.

The opening of this plant is an opportunity to bring these benefits closer to the local population. The Alexander First Nation will be able to produce pipes that meet international standards while also addressing local needs. The plant’s operations will boost the quality of life for residents by ensuring reliable, safe, and sustainable piping systems.

Benefits of the HDPE Pipes Plant for the Local Economy

The HDPE pipes plant offers numerous economic benefits to the Alexander First Nation. It will create jobs, stimulate local businesses, and provide a steady source of income. The community will see direct employment opportunities in manufacturing, logistics, and administration. Additionally, the plant will require a variety of supporting industries, such as raw material suppliers, maintenance services, and transportation.

The First Nation has also indicated that it plans to work with local educational institutions to train workers in the skills needed for the plant. This will enhance long-term career prospects for young members of the community, providing them with valuable experience in a growing industry.

How the HDPE Pipes Plant Supports Local Infrastructure Projects

The HDPE pipes produced by the new plant will be instrumental in supporting critical infrastructure projects within the community and surrounding regions. In areas with aging infrastructure or those requiring upgrades, the demand for reliable and durable pipes is high. The HDPE plant can provide pipes that meet these needs, ensuring that essential utilities like water and sewage are delivered safely and efficiently.

Additionally, the plant can offer pipes for new construction projects, whether for residential, commercial, or industrial purposes. The availability of locally produced pipes reduces dependence on external suppliers, cutting down transportation costs and delivery times. This localized production will also result in a more reliable supply chain.

The Environmental Impact of HDPE Pipe

Environmental sustainability is a key concern for many communities, and the Alexander First Nation is no exception. HDPE pipes are known for being environmentally friendly. They are fully recyclable and have a lower carbon footprint compared to traditional materials like concrete or metal pipes.

The new plant will adhere to environmentally responsible practices by using clean energy sources and minimizing waste. Furthermore, the long lifespan of HDPE pipes reduces the frequency of replacements, leading to fewer raw materials being used over time. This aligns with the First Nation’s ongoing commitment to ecological preservation.

Training and Employment Opportunities in the HDPE Pipe Plant

One of the key goals of the Alexander First Nation’s HDPE pipes plant is to provide extensive training and employment opportunities for local residents. The community has already started working with educational institutions to develop training programs aimed at equipping young people with the necessary skills to work in the plant.

Job roles in the HDPE pipes plant will range from machine operators and quality control technicians to logistics coordinators and maintenance staff. This initiative will contribute to the skill development of the local workforce, enabling members of the community to secure stable jobs in an expanding sector.

Collaboration with Local and International Partners

The success of the HDPE pipes plant will rely not only on the internal resources of the Alexander First Nation but also on collaborations with local and international partners. The plant will require advanced technologies, raw materials, and technical expertise that may be sourced from outside the community.

By fostering relationships with industry leaders and manufacturers, the First Nation can ensure that its operations are competitive and efficient. This collaboration will also help build the community’s reputation as a serious player in the global pipe manufacturing industry, attracting potential customers from other regions and countries.

The Future of the HDPE Pipe Plant in Alexander First Nation

The future of the HDPE pipes plant looks promising. The growing demand for infrastructure development in Canada and around the world positions the plant to play a vital role in meeting these needs. The community plans to expand its operations in the future, potentially increasing its capacity and range of products.

As the plant continues to grow, it could serve as a model for other Indigenous communities seeking to diversify their economies and create sustainable, long-term jobs. The Alexander First Nation is laying the foundation for a brighter, self-sufficient future, driven by innovation and community-centered growth.

FAQs

1. What are HDPE pipes used for?

People primarily use HDPE pipes for water and sewage systems, but they also use them in oil and gas pipelines and telecommunications.

2. What makes HDPE pipes environmentally friendly?

HDPE pipes are fully recyclable, have a lower carbon footprint, and require fewer replacements due to their long lifespan.

3. Will the new plant create job opportunities for local residents?

Yes, the plant will create jobs in manufacturing, logistics, quality control, and administration, providing long-term employment for local community members.

4. How does the new HDPE pipes plant contribute to local infrastructure?

The plant will produce high-quality pipes for water, sewage, and other infrastructure projects, helping improve local utilities and construction.

5. Will the Alexander First Nation collaborate with other organizations for this project?

The First Nation plans to collaborate with local schools, industry leaders, and global partners to ensure the plant’s success.