Introduction

The plumbing industry continues to evolve with new technologies and materials that aim to improve efficiency, reduce costs, and increase sustainability. One such innovation is the use of fused plastic plumbing pipe fittings in trenchless pipe applications. This technique is gaining traction as a cost-effective, environmentally friendly, and efficient solution for installing or repairing pipes without the need for traditional trenching. In this article, we’ll explore how fused plastic plumbing pipe fittings are transforming trenchless technology and why they’re becoming a preferred choice for many plumbing professionals and contractors.

What Are Fused Plastic Plumbing Pipe Fittings?

Defining Fused Plastic Plumbing Pipe Fittings

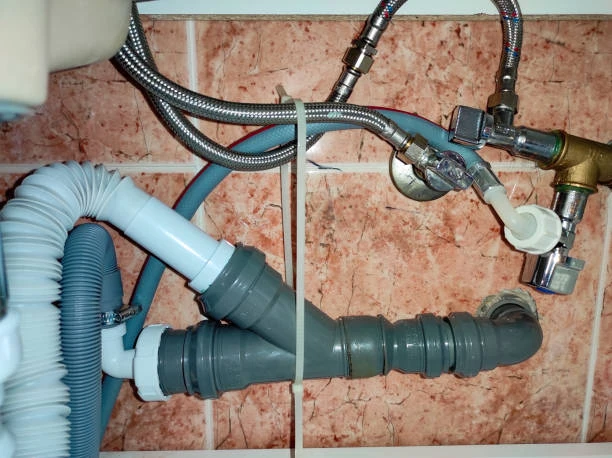

Fused plastic plumbing pipe fittings consist of plastic materials that manufacturers fuse or join together using heat or chemical bonding processes. These fittings commonly serve water and sewage systems, providing advantages such as corrosion resistance, cost-effectiveness, and ease of installation. The fusion process ensures that the joints are seamless, creating a continuous, durable pipe network.

Commonly used materials for fused plastic plumbing fittings include:

- PVC (Polyvinyl Chloride)

- HDPE (High-Density Polyethylene)

- PP (Polypropylene)

These materials are known for their strength, flexibility, and resistance to harsh chemicals and environmental factors, making them ideal for use in trenchless applications.

What Is Trenchless Pipe Installation?

Explaining Trenchless Technology

@GPT-4o Trenchless technology installs or repairs underground pipes, making large-scale excavation or trenching unnecessary. This technique minimizes disruption to the surrounding environment and reduces costs associated with traditional digging. Trenchless methods include techniques like horizontal directional drilling (HDD), pipe bursting, and sliplining.

By using trenchless methods, contractors can install new pipes or replace existing ones with minimal surface disturbance, reducing the impact on roads, landscaping, and utilities.

Why Are Fused Plastic Plumbing Pipe Fittings Ideal for Trenchless Applications?

1. Durability and Longevity

One of the most important characteristics of fused plastic plumbing fittings is their durability. These fittings resist corrosion, which is crucial in underground applications where moisture, soil, and harsh chemicals expose pipes. The seamless nature of fused plastic joints ensures that there are fewer points of failure, increasing the longevity of the piping system.

In trenchless pipe applications, where challenging conditions may arise during installation, this added durability ensures a long-lasting and reliable solution for both water and wastewater systems.

2. Flexibility and Adaptability

Fused plastic pipe fittings are highly flexible, making them suitable for trenchless installation methods. Their ability to bend and adjust to various shapes and curves in the underground environment ensures that the piping system remains intact and functional. Flexibility also makes it easier to navigate obstacles and reduce the need for extensive rerouting during installation.

For methods like horizontal directional drilling, which involve installing pipes at various angles, fused plastic plumbing fittings serve as an excellent choice.

3. Cost-Effective Solution

When compared to traditional pipe materials like metal, fused plastic plumbing pipe fittings are a more affordable solution. They are lightweight, reducing both material costs and labor expenses during installation. The reduced need for excavation and disruption of the surrounding environment also saves time and money, making fused plastic an economical choice for trenchless applications.

4. Seamless and Leak-Free Joints

Fused plastic fittings offer a seamless connection between pipes. This minimizes the risk of leaks, which can be a significant concern with other pipe materials. Leak-free joints contribute to the overall efficiency of the pipe system and reduce the likelihood of costly repairs or maintenance down the line.

For trenchless applications, where access to the pipes can be difficult and costly, ensuring that the joints are secure and leak-proof is crucial to the success of the project.

5. Resistance to Chemicals and Corrosion

Plastic materials like PVC and HDPE are highly resistant to corrosion, which is a major advantage over metal pipes. These pipes are less likely to degrade when exposed to acidic or alkaline environments, which is particularly important for water treatment plants, sewage systems, and other industrial applications.

In trenchless installations, where pipes often face harsh underground conditions, the resistance to corrosion and chemicals ensures that the pipes remain intact for years, even in aggressive environments.

Trenchless Methods That Benefit from Fused Plastic Plumbing Pipe Fittings

1. Horizontal Directional Drilling (HDD)

Horizontal directional drilling (HDD) is one of the most popular trenchless technologies used for the installation of pipes. It involves drilling a pilot hole along the desired path, followed by reaming out the hole to a larger diameter. The pipe is then pulled through the hole. Fused plastic plumbing fittings are ideal for this method due to their flexibility, durability, and ease of installation.

2. Pipe Bursting

Pipe bursting involves breaking apart an existing pipe while simultaneously pulling a new pipe into place. This method commonly replaces old, worn-out pipes. Fused plastic pipe fittings excel in pipe bursting because they resist the mechanical stresses of the bursting process and easily connect to new pipes.

3. Sliplining

Sliplining rehabilitates existing pipes by inserting a smaller pipe into an old pipe to improve the system’s overall structural integrity. Fused plastic fittings provide the necessary strength and flexibility to connect the new pipe to the existing system while maintaining a leak-free and durable joint.

The Future of Fused Plastic Plumbing Pipe Fittings in Trenchless Applications

As technology continues to evolve, the use of fused plastic plumbing pipe fittings in trenchless applications will only expand. The future of the market looks promising for several reasons:

- Advancements in Material Science: Manufacturers are constantly developing new, improved plastic materials that are even more durable, flexible, and resistant to chemicals, ensuring that trenchless installations remain reliable for many years.

- Increased Demand for Trenchless Solutions: As urbanization grows and infrastructure ages, the demand for efficient and non-invasive methods of pipe installation and repair will rise. Fused plastic plumbing fittings will continue to play a major role in meeting this demand.

- Sustainability Efforts: As industries shift toward more sustainable practices, the use of recycled and eco-friendly plastics in pipe fittings will become more common. This will enhance the environmental appeal of fused plastic plumbing fittings, especially in applications like water conservation and wastewater treatment.

Conclusion

Fused plastic plumbing pipe fittings have revolutionized the way trenchless pipe installations are carried out. With benefits such as durability, cost-effectiveness, flexibility, and seamless joints, these fittings provide a highly reliable solution for a wide range of trenchless applications. As the industry continues to grow and evolve, more professionals will adopt fused plastic plumbing fittings, driven by advancements in material science and an expanding focus on sustainable practices. Whether it’s for new installations or repairs, fused plastic pipe fittings are the future of trenchless technology.

FAQs

1. What are the benefits of using fused plastic plumbing pipe fittings for trenchless applications?

Fused plastic plumbing fittings offer durability, cost-effectiveness, flexibility, and resistance to corrosion and chemicals, making them ideal for trenchless installations that require minimal surface disruption.

2. What trenchless methods benefit from fused plastic plumbing pipe fittings?

Methods such as Horizontal Directional Drilling (HDD), pipe bursting, and sliplining rely on fused plastic fittings, which provide the flexibility and durability needed for successful installation and repair.

3. How do fused plastic plumbing fittings improve leak resistance?

The fusion process creates seamless joints between pipes, which significantly reduces the chances of leaks, ensuring a more reliable and long-lasting piping system.

4. Are fused plastic plumbing pipe fittings environmentally friendly?

Yes, fused plastic pipe fittings are generally more eco-friendly compared to traditional metal piping. Additionally, many manufacturers are working on producing recyclable and sustainable plastic materials.

5. Will fused plastic plumbing pipe fittings continue to grow in popularity?

Yes, as the demand for trenchless pipe installation methods increases and sustainable solutions become more critical, fused plastic pipe fittings will likely see widespread adoption in the plumbing industry.