Introduction

In recent years, the importance of recycling has surged, particularly in the plastics industry. High-Density Polyethylene (HDPE) and Polypropylene (PP) are two widely used materials that play a critical role in various applications, including packaging, piping, and automotive components. For Turkish plastics recyclers, establishing an efficient recycling line for HDPE pipe and PP products can significantly contribute to sustainability efforts and economic growth. This article delves into the intricacies of setting up an HDPE pipe and PP recycling line, emphasizing its benefits, processes, and best practices.

Understanding HDPE Pipeand PP

What is HDPE Pipe?

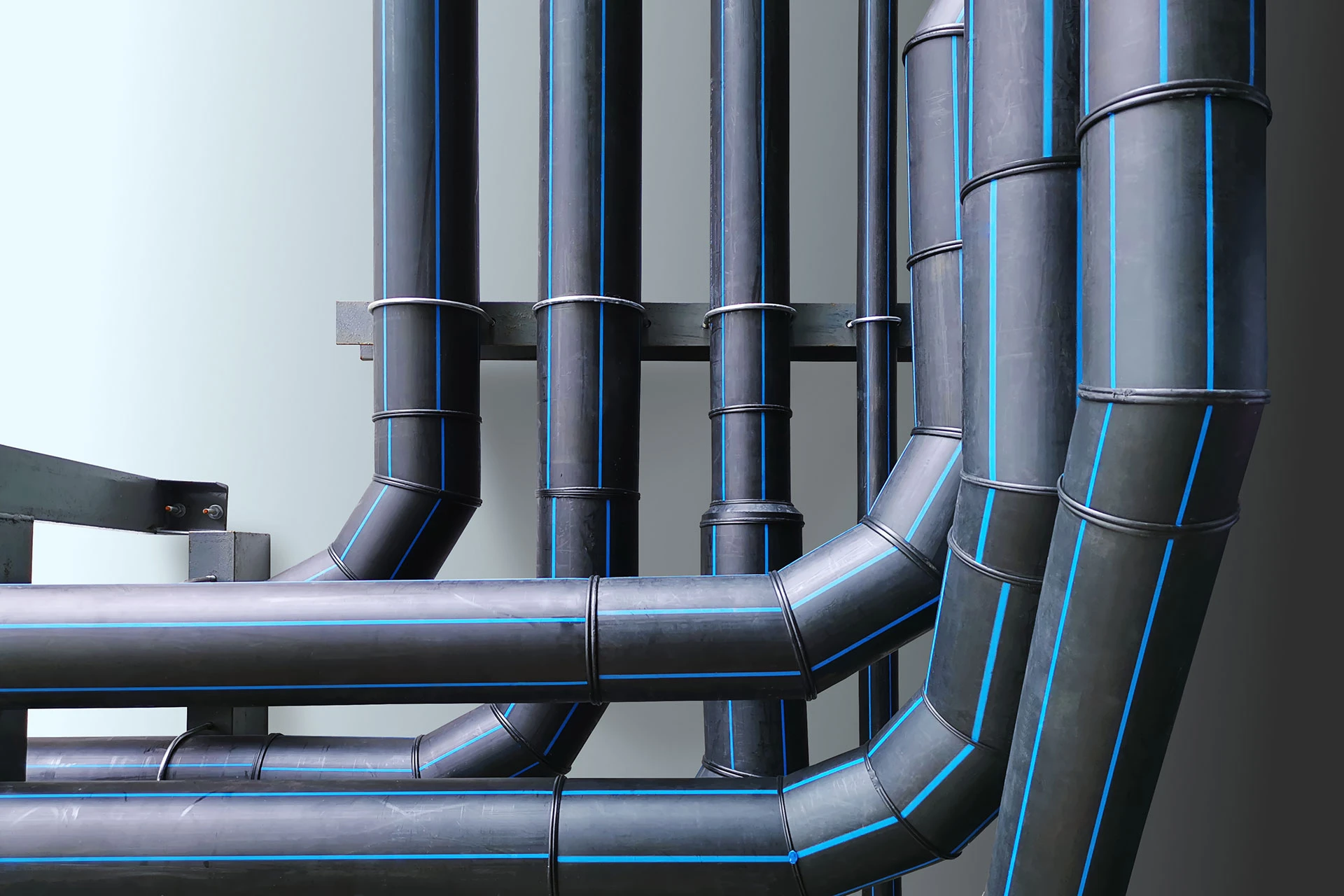

High-Density Polyethylene (HDPE) is a versatile plastic known for its strength, durability, and resistance to impact and chemicals. It is commonly used in manufacturing pipes, containers, and various household items. Due to its excellent recyclability, HDPE is a popular choice for recycling programs worldwide.

What is PP?

Polypropylene (PP) is another widely used thermoplastic, recognized for its lightweight nature, flexibility, and heat resistance. Commonly found in packaging, automotive parts, and textiles, PP is also highly recyclable, making it an attractive option for recycling initiatives.

The Need for HDPE Pipe Recycling in Turkey

Turkey has experienced rapid industrial growth, leading to increased plastic consumption. However, this growth has also resulted in significant plastic waste. Establishing a dedicated recycling line for HDPE and PP can address environmental concerns while creating economic opportunities in the recycling sector.

HDPE Pipe Environmental Impact

Plastic waste poses a severe environmental threat, contributing to land pollution and marine debris. By recycling HDPE and PP, Turkish recyclers can reduce the volume of waste sent to landfills and minimize environmental harm.

Economic Opportunities

The recycling industry offers substantial economic benefits, including job creation and the production of recycled materials for various applications. Establishing an efficient recycling line can position Turkey as a leader in the regional recycling market.

Setting Up an HDPE Pipe and PP Recycling Line

1.HDPE Pipe Planning and Design

Assessing Needs

Before setting up a recycling line, it’s essential to assess the specific needs of the operation. This includes understanding the volume of materials to be processed, available space, and budget constraints.

Designing the Workflow

An effective workflow is crucial for maximizing efficiency. The design should consider the sequence of operations, from material collection to processing and output.

2. Equipment Selection

Selecting the right equipment is vital for the successful operation of a recycling line. Key equipment includes:

- Shredders: To reduce the size of HDPE pipes and PP products for easier processing.

- Washing Systems: To remove contaminants and impurities, ensuring high-quality recycled materials.

- Extruders: To melt and reshape the cleaned plastic into pellets or other forms for resale.

- Sorting Systems: For separating different types of plastics and ensuring quality control.

3. HDPE Pipe Processing Techniques

Shredding

The first step in the recycling process involves shredding HDPE pipes and PP products into smaller pieces. This increases the surface area and facilitates easier washing and melting.

Washing

After shredding, the materials must be washed to remove dirt, labels, and other contaminants. Efficient washing systems are essential to achieve high-quality recycled plastic.

Extrusion

Once the materials are clean, they are melted and extruded into pellets. This step is crucial for creating a uniform product that can be easily reused in manufacturing processes.

4. HDPE Pipe Quality Control

Implementing a robust quality control system is essential for ensuring that the recycled materials meet industry standards. Regular testing and monitoring of the end products will help maintain quality and boost customer confidence.

5. HDPE Pipe Compliance and Regulations

Adhering to local regulations and standards is critical when setting up a recycling line. Turkish recyclers must ensure compliance with environmental laws and obtain necessary permits for their operations.

Benefits of HDPE Pipe and PP Recycling

1. HDPE Pipe Resource Conservation

Recycling HDPE and PP reduces the demand for virgin materials, conserving natural resources and energy in the production process.

2. Reduced Landfill Waste

By recycling plastics, Turkish recyclers can significantly decrease the volume of waste sent to landfills, contributing to a cleaner environment.

3. Lower Carbon Footprint

Recycling processes generally produce fewer greenhouse gas emissions compared to producing new plastics. This reduction contributes to a smaller carbon footprint and promotes sustainability.

4. Economic Growth

The establishment of a recycling line can create jobs in the local economy, from collection and processing to sales and distribution of recycled materials.

5. Innovation and Research Opportunities

The growing demand for recycled plastics encourages research and innovation in recycling technologies, leading to more efficient processes and higher-quality end products.

Conclusion

Setting up an HDPE pipe and PP recycling line in Turkey presents a significant opportunity for environmental sustainability and economic development. By implementing efficient processes and adhering to quality standards, Turkish recyclers can play a crucial role in reducing plastic waste while benefiting from the growing demand for recycled materials. As the global focus on sustainability intensifies, investing in recycling infrastructure will be vital for the future of the plastics industry in Turkey.

Frequently Asked Questions (FAQs)

1. What types of plastics can be recycled alongside HDPE and PP?

Commonly recycled plastics include PET, PVC, and LDPE, among others.

2. How can recyclers ensure high-quality recycled materials?

Implementing stringent washing and sorting processes, along with regular quality testing, is essential.

3. What are the economic benefits of setting up a recycling line?

Benefits include job creation, reduced production costs, and potential revenue from selling recycled materials.

4. Are there any government incentives for recycling initiatives in Turkey?

Yes, the Turkish government often provides incentives and support for sustainable recycling projects.

5. How does recycling contribute to environmental sustainability?

Recycling conserves natural resources, reduces landfill waste, and lowers greenhouse gas emissions, contributing to a healthier environment.