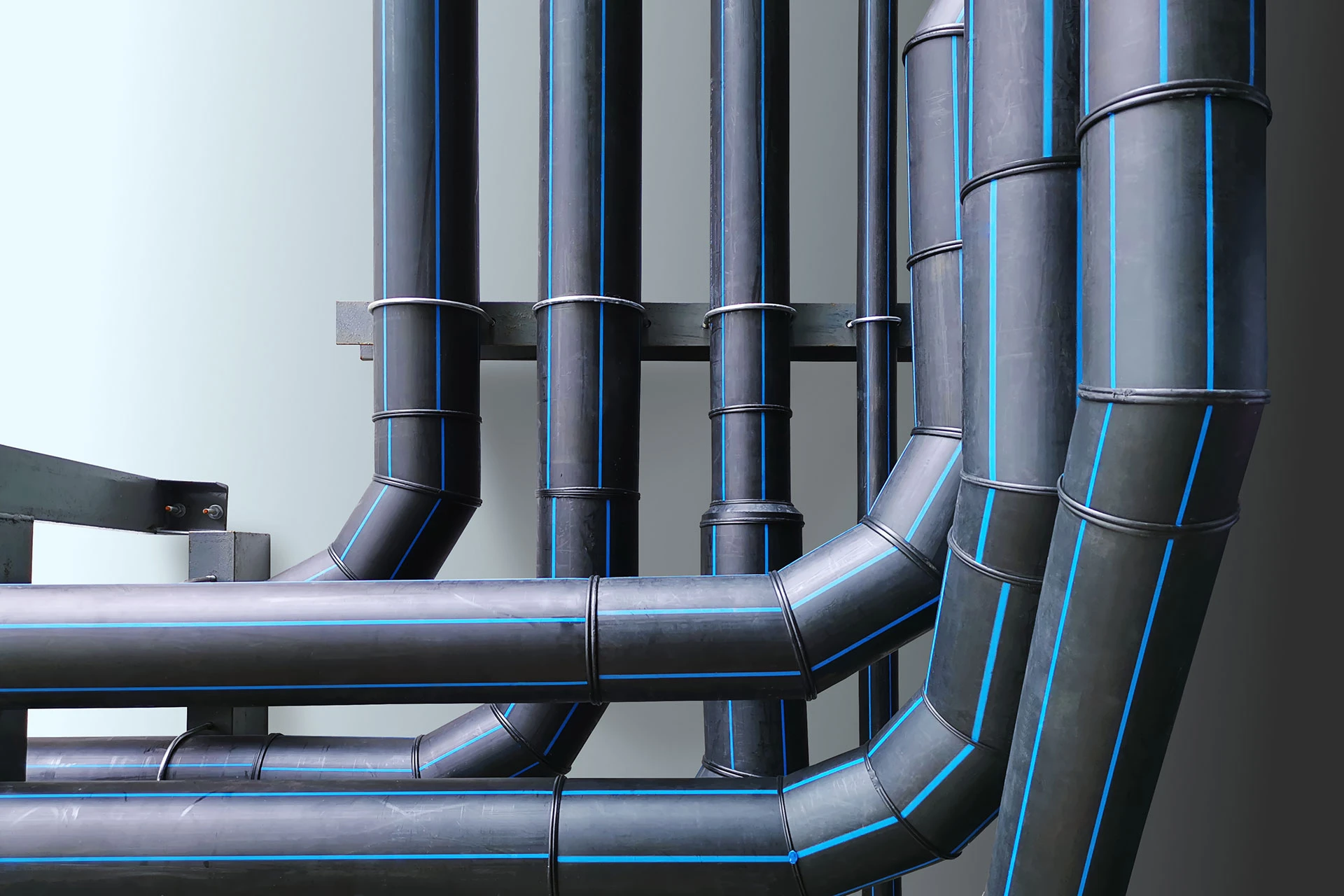

High-Density Polyethylene HDPE pipes have emerged as a go-to solution across various industries, thanks to their efficiency, durability, and sustainability. From municipal water systems to agricultural applications, HDPE pipes are redefining standards in piping technology. A crucial component that enhances the performance and installation of these pipes is the use of pipe press fittings. This article explores the efficiency of HDPE pipes in all sectors and underscores the importance of pipe press fittings in maximizing their potential.

Understanding HDPE Pipes

What is HDPE?

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its high strength-to-density ratio. This material is incredibly versatile and is used in various applications, making it one of the most popular choices in the piping industry.

Key Features of HDPE Pipes

- Durability: HDPE pipes are resistant to corrosion, chemicals, and impact, leading to longer service life compared to traditional materials like PVC and metal.

- Flexibility: Their flexibility allows them to be installed in challenging terrains and environments, accommodating ground movement without cracking.

- Low Maintenance: HDPE requires minimal maintenance, which lowers long-term operational costs and improves overall efficiency.

- Environmentally Friendly: HDPE is recyclable and can be produced from post-consumer materials, supporting sustainable development goals.

HDPE pipes Efficiency Across Sectors

HDPE pipes are proving their efficiency in various sectors, including:

1. HDPE pipes Municipal Water Supply

In municipal water supply systems, HDPE pipes are increasingly replacing traditional materials due to their superior performance and longevity.

- Leak Reduction: With fewer joints and a robust design, HDPE significantly reduces leakage, ensuring more efficient water distribution.

- Pressure Resistance: HDPE pipes can withstand high pressure, making them suitable for urban water supply systems where fluctuations in pressure are common.

2. Wastewater Management

HDPE is ideal for wastewater management systems, as it resists chemical degradation and is not prone to rust or corrosion.

- Durability in Harsh Environments: The resilience of HDPE allows it to thrive in harsh conditions often found in wastewater treatment plants.

- Joint Integrity: The use of pipe press fittings enhances joint integrity, reducing the risk of leaks and improving system reliability.

3. Agriculture

Agricultural applications benefit from HDPE pipes, especially in irrigation systems.

- Water Conservation: The smooth interior surface of HDPE pipes minimizes friction loss, allowing for efficient water flow and reducing water consumption.

- Flexible Installation: Their flexibility allows for easier installation in varied terrains, making them ideal for farms with uneven ground.

4. Industrial Applications

HDPE pipes are used in various industrial applications, from transporting chemicals to cooling water systems.

- Chemical Resistance: HDPE’s resistance to a wide range of chemicals makes it suitable for industrial processes that involve corrosive substances.

- Reduced Downtime: With low maintenance requirements, HDPE pipes contribute to reduced downtime in industrial operations, enhancing overall productivity.

The Role of HDPE pipes Press Fittings

Pipe press fittings are essential components that enhance the performance and efficiency of HDPE piping systems. Here’s why they are crucial:

1. Quick Installation

One of the primary advantages of pipe press fittings is their ease of installation. The pressing technique eliminates the need for welding or adhesives, allowing for faster connections.

- Time Savings: Quick installation translates to reduced labor costs and faster project completion times, making them ideal for urgent applications.

2. Secure Connections

The technology behind pipe press fittings ensures tight and secure connections that minimize the risk of leaks.

- Leak Prevention: Reliable connections are particularly critical in applications involving pressurized fluids, such as municipal water and industrial processes.

3. Versatility

Pipe press fittings can be use across a wide range of applications, making them adaptable to various sectors.

- Compatibility: These fittings work seamlessly with HDPE pipes and can also be use with other materials, providing flexibility in installation.

4. Cost Efficiency

By reducing installation time and the risk of leaks, pipe press fittings contribute to long-term cost savings.

- Lower Maintenance Costs: Secure connections reduce the need for frequent repairs and maintenance, further enhancing cost efficiency.

Installation Best Practices for HDPE Pipes and Pipe Press Fittings

To fully leverage the benefits of HDPE pipes and pipe press fittings, following best practices during installation is crucial:

1. Preparation

Ensure that all materials are clean and free from debris before installation. This will help achieve a secure fit and reduce the likelihood of leaks.

2. Use Appropriate Tools

Employ the right tools designed specifically for pressing fittings. Using manufacturer-recommended tools ensures optimal performance and connection integrity.

3. Follow Manufacturer Guidelines

Always refer to the manufacturer’s installation guidelines for both HDPE pipes and pipe press fittings. Adhering to these guidelines ensures compliance with safety and performance standards.

4. Conduct Regular Inspections

After installation, routine inspections are vital to monitor the integrity of the system. Check for signs of wear, stress, or potential leaks.

Future Trends in HDPE pipe

As the demand for sustainable and efficient piping solutions continues to grow, HDPE pipe are expecte to play an increasingly significant role across various sectors. The integration of advanced technologies, such as smart piping systems and improved materials, will further enhance the capabilities of HDPE pipe.

Conclusion

HDPE pipe are proving to be efficient solutions in all sectors, thanks to their durability, flexibility, and environmental sustainability. The incorporation of pipe press fittings significantly enhances the performance and reliability of these piping systems, making them a preferred choice for contractors and engineers alike. As industries continue to prioritize efficiency and sustainability, HDPE pipe and their accompanying technologies will undoubtedly lead the way.

FAQs

- What are the main advantages of HDPE pipe? HDPE pipe are durable, flexible, low maintenance, and environmentally friendly, making them ideal for various applications.

- How do pipe press fittings work? Pipe press fittings create secure connections through a pressing technique, eliminating the need for welding or adhesives.

- In which sectors are HDPE pipe commonly used? HDPE pipe are widely use in municipal water supply, wastewater management, agriculture, and industrial applications.

- What are the best practices for installing HDPE pipe? Proper preparation, using appropriate tools, following manufacturer guidelines, and conducting regular inspections are essential for effective installation.

- How do pipe press fittings contribute to cost savings? They reduce installation time and the risk of leaks, which lowers labor costs and minimizes long-term maintenance expenses.