In the ever-evolving landscape of industrial infrastructure, the demand for reliable, efficient, and durable piping solutions continues to rise. High-pressure pipe systems have become essential for a variety of applications, including oil and gas, chemical processing, and water transportation. This article explores the latest advancements in high-pressure pipe systems, focusing on their benefits, applications, and the technology behind them.

Understanding High-Pressure Pipe Systems

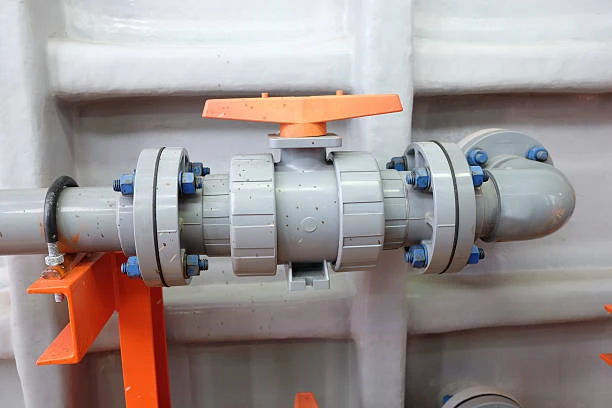

Manufacturers specifically design high-pressure pipe systems to withstand elevated pressures commonly found in industrial environments. They construct these pipes from materials that provide strength and resistance to corrosion, making them suitable for transporting liquids and gases under high pressure. Common materials used include carbon steel, stainless steel, and high-density polyethylene (HDPE), each offering unique advantages depending on the application.

Key Features of High-Pressure Pipe Systems

- Durability: Engineers design high-pressure pipes to endure extreme conditions, subjecting them to rigorous testing to ensure they can withstand high pressure and temperature fluctuations.

- Corrosion Resistance: Many manufacturers apply coatings or use corrosion-resistant materials in high-pressure pipe systems, extending their lifespan and reducing maintenance costs.

- Flexibility: Some systems, particularly those using HDPE, offer greater flexibility compared to traditional materials, allowing for easier installation in challenging environments.

- Customizability: High-pressure pipe systems can be tailored to meet specific needs, including different diameters, lengths, and pressure ratings.

Applications of High-Pressure Pipe Systems

High-pressure pipe systems are utilized across various industries. Here are some key applications:

1. Oil and Gas Industry

In the oil and gas sector, high-pressure pipes are essential for transporting crude oil, natural gas, and other hydrocarbons from extraction sites to processing facilities. Their ability to handle extreme pressures and corrosive substances makes them indispensable for ensuring the safe and efficient movement of resources.

2. Chemical Processing

Chemical plants often operate under high pressures and temperatures. High-pressure pipe systems facilitate the transportation of hazardous materials while maintaining safety standards. These systems must adhere to stringent regulations to prevent leaks and ensure environmental protection.

3. Water Transportation

High-pressure pipes are also used in municipal water supply systems, particularly in areas where water needs to be transported over long distances or through elevated terrains. They ensure that water reaches consumers efficiently and reliably.

4. Mining Operations

In mining, high-pressure pipe systems are used for transporting slurries and other materials. Their durability and resistance to wear make them ideal for harsh environments where traditional piping may fail.

5. Power Generation

High-pressure pipes play a crucial role in power generation, particularly in steam generation and distribution systems. They transport steam and water at high pressures, contributing to efficient energy production.

Advantages of High-Pressure Pipe Systems

1. Enhanced Safety

Safety is paramount in any industrial operation. High-pressure pipes systems are designed to minimize the risk of leaks and bursts, which can lead to catastrophic failures. Their robust construction and rigorous testing contribute to safer working environments.

2. Cost Efficiency

Although the initial investment may be higher, high-pressure pipes systems often lead to long-term cost savings. Their durability reduces the need for frequent replacements and maintenance, and their efficiency can lower operational costs.

3. Increased Efficiency

High-pressure systems can transport fluids and gases more efficiently than lower-pressure alternatives, reducing energy consumption and improving overall system performance.

4. Environmental Protection

By minimizing leaks and failures, high-pressure pipe systems contribute to environmental protection. They help prevent spills that could harm ecosystems and human health.

Recent Innovations in High-Pressure Pipe Systems

The industry continues to innovate, leading to enhanced performance and reliability. Some notable advancements include:

1. Advanced Materials

The introduction of new materials, such as high-strength alloys and composite materials, has improved the performance of high-pressure pipes. These materials offer better resistance to corrosion, wear, and temperature fluctuations.

2. Smart Technology

Integrating smart technology into high-pressure pipes systems allows for real-time monitoring of pressure, temperature, and flow rates. This data can be used to optimize performance, prevent failures, and enhance maintenance schedules.

3. Improved Joining Techniques

Innovations in welding and joining techniques have resulted in stronger connections, further enhancing the integrity of high-pressure systems. These advancements help reduce the likelihood of leaks and failures.

4. Sustainability Efforts

Many manufacturers are focusing on sustainability, utilizing recyclable materials and eco-friendly production processes. This commitment helps reduce the environmental impact of high-pressure pipe systems.

The Future of High-Pressure Pipe Systems

As industries evolve, the demand for high-pressure pipes systems is expected to grow. With the ongoing focus on safety, efficiency, and sustainability, manufacturers will continue to innovate and improve their offerings.

Key Trends to Watch

- Increased Automation: The use of automated systems for monitoring and controlling high-pressure piping networks will become more common, enhancing operational efficiency and safety.

- Focus on Sustainability: As regulations around environmental protection tighten, the push for sustainable materials and processes in high-pressure pipes systems will gain momentum.

- Global demand is driving the projected expansion of the high-pressure pipe market, fueled by increasing needs from developing economies and advancements in technology.

Conclusion

High-pressure pipe systems play a crucial role in various industries, providing reliable and efficient solutions for transporting fluids and gases under extreme conditions. With ongoing innovations in materials, technology, and sustainability, these systems are poised for continued growth and development. Choosing the right high-pressure pipe system significantly enhances operational efficiency and safety, making it an essential investment for any industrial application.

FAQs

1. What are high-pressure pipes systems used for?

Industries use high-pressure pipe systems to transport liquids and gases in various sectors, including oil and gas, chemical processing, water supply, mining, and power generation.

2. What materials are commonly used for high-pressure pipes?

Common materials include carbon steel, stainless steel, and high-density polyethylene (HDPE), each offering unique benefits for different applications.

3. How do I determine the right high-pressure pipes system for my needs?

Consider factors such as the type of fluid you are transporting, the pressure requirements, temperature conditions, and environmental factors. Consulting with an expert can help you make the best choice.

4. Are high-pressure pipes systems safe?

Yes, manufacturers design high-pressure pipe systems with safety in mind, featuring robust construction and rigorous testing to minimize the risk of leaks and failures.

5. What is the expected lifespan of high-pressure pipes?

The lifespan of high-pressure pipes varies depending on the material, application, and maintenance practices. Generally, they can last for several decades with proper care and monitoring.