Introduction

Plastic machinery exporters are at the forefront of this transformation, particularly in the realm of pe pipe manufacturing. This article explores the dynamic landscape of PE pipe exports, the machinery behind its production, and the trends shaping the industry.

Understanding EN 12201

Definition and Properties

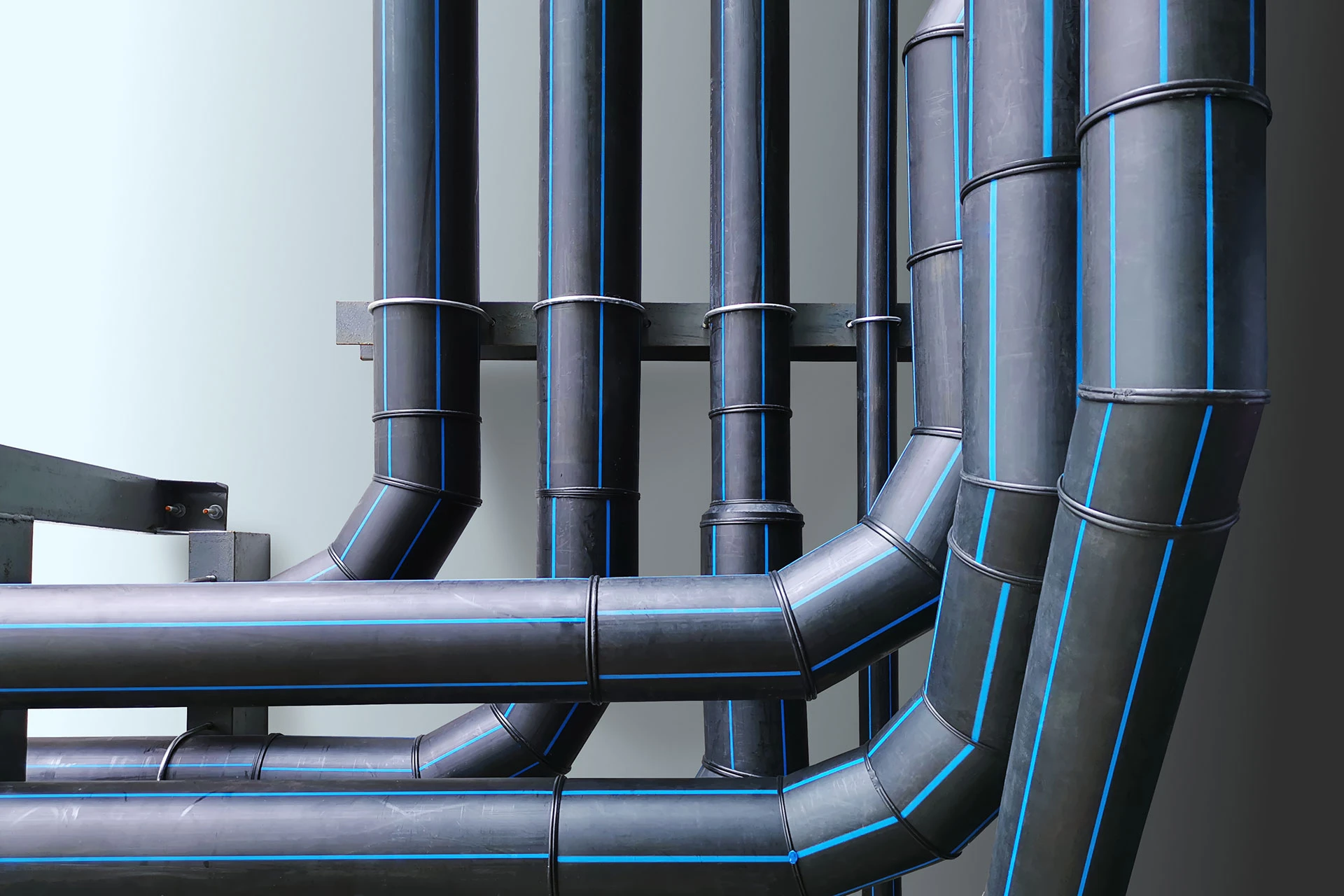

PE pipe, made from high-density polyethylene, is renowned for its durability, flexibility, and resistance to corrosion. These qualities make it an ideal choice for various applications, from water distribution systems to gas pipelines.

Applications of PE Pipe

PE pipes are versatile and used in numerous sectors, including:

- Water Supply: Ensuring safe drinking water reaches communities.

- Sewage and Waste Management: Effectively handling wastewater.

- Industrial Applications: Supporting various manufacturing processes.

The Role of Plastic Machinery in PE Pipe Production

Types of Machinery Used

Plastic machinery plays a crucial role in the production of PE pipes. Key types include:

- Extruders: For shaping and forming PE materials into pipes.

- Injection Molding Machines: Used for creating fittings and connectors.

- Blow Molding Machines: For producing hollow structures.

Innovations in Technology

Advancements in technology have significantly improved the efficiency and quality of PE pipe production. Automated systems and advanced control mechanisms enhance precision and reduce waste.

Market Trends in PE Pipe Exports

Global Demand for PE Pipe

The global market for PE pipes is expanding rapidly, driven by increasing investments in infrastructure and the need for sustainable solutions. Countries are focusing on upgrading aging water systems, creating opportunities for exporters.

Key Markets for Exporters

Regions such as North America, Europe, and Asia-Pacific are leading markets for PE pipe exports. Emerging economies are also ramping up their infrastructure projects, making them attractive destinations for exporters.

Challenges Faced by Plastic Machinery Exporters

Regulatory Hurdles

Navigating export regulations can be complex. Different countries have varying standards for PE pipe quality, which can complicate the export process.

Competition and Market Saturation

As the demand for PE pipes grows, so does competition. Exporters must differentiate themselves through quality, innovation, and customer service.

The Importance of Quality Assurance

Standards for PE pipe Production

Adhering to strict quality standards is vital for successful exports. Organizations like ASTM International and ISO provide guidelines that ensure PE pipes meet safety and performance criteria.

Role of Certifications in Exports

Certifications are crucial in establishing credibility in international markets. They assure customers that products meet specific quality standards.

Sustainability in EN 12201 Manufacturing

Eco-Friendly Practices

Sustainability is becoming increasingly important in the manufacturing sector. Many plastic machinery exporters are adopting eco-friendly practices to minimize their environmental impact.

Recycling and End-of-Life Considerations

PE pipes can be recycled, and companies are exploring ways to incorporate recycled materials into their production processes, further enhancing sustainability.

Case Studies: Successful Exporters

Profiles of Notable Exporters

Several companies stand out in the it export market. For instance, XYZ Plastics has successfully navigated regulatory challenges by investing in compliance training for their team, resulting in increased exports.

Lessons Learned from Their Success

Successful exporters share common traits: a commitment to quality, innovative practices, and an understanding of market dynamics.

The Future of EN 12201 Exports

Innovations on the Horizon

The future looks promising for it exports, with ongoing innovations in manufacturing processes and materials that enhance performance and sustainability.

Predictions for Market Growth

Analysts predict continued growth in the it market, driven by infrastructure investments and the need for sustainable solutions.

Conclusion

The News Center of Plastic Machinery Exporters highlights the vital role of PE pipe in modern infrastructure and the machinery that drives its production. As the demand for quality and sustainability grows, stakeholders in the industry must adapt and innovate to meet the challenges and seize opportunities.