Introduction

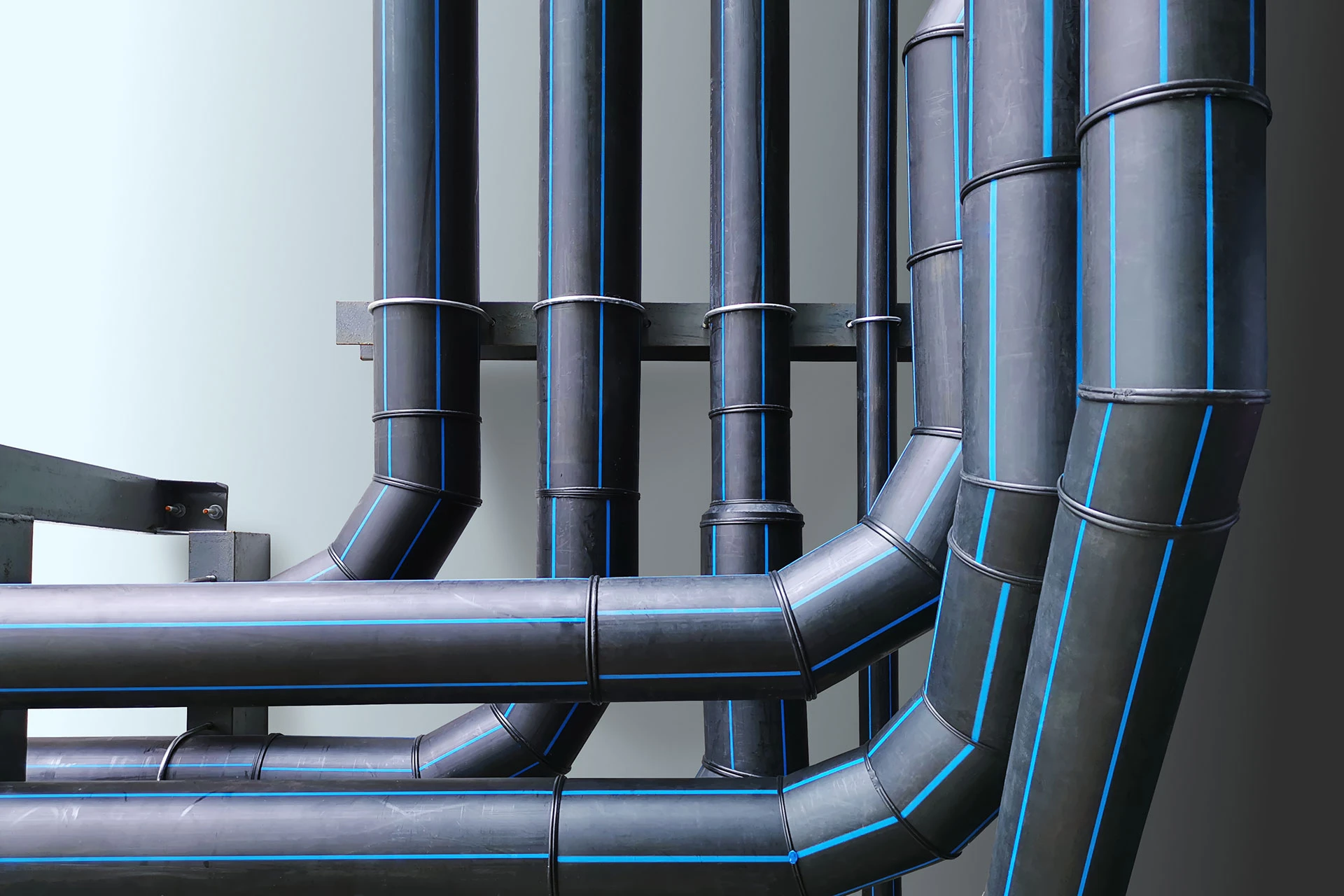

The PE Pipe resin market plays a pivotal role in modern infrastructure, catering to a wide array of applications, from water supply systems to gas distribution. As industries increasingly prioritize durability and sustainability, the demand for PE pipe resin continues to rise. But what factors are driving this growth, and who are the key players in the market? Let’s dive in!

Market Overview

In recent years, the PE pipe resin market has witnessed significant transformation, with an increasing emphasis on high-performance materials. Current trends indicate a shift towards more environmentally friendly solutions, as industries seek to reduce their carbon footprint. According to market projections, heightened investments in infrastructure globally will drive substantial growth in this sector.

North America

North America remains a robust market for PE pipe resin, bolstered by extensive infrastructure development projects. The US leads in consumption, with major players like LyondellBasell and DuPont dominating the landscape. The region’s focus on sustainability and innovation fuels further growth.

Asia-Pacific

The Asia-Pacific region is experiencing unprecedented growth in the PE pipe resin market. Rapid urbanization and industrialization, particularly in countries like China and India, are major contributors. Here, local and international players are vying for market share, making it a highly competitive environment.

Major Players in the Market

LyondellBasell

LyondellBasell is a leading name in the PE pipe resin industry, known for its innovation and extensive product range. With a strong market share, the company focuses on developing sustainable solutions to meet evolving customer demands.

Factors Driving Market Demand

- Growing Infrastructure Projects: As governments worldwide invest in infrastructure, the need for reliable piping systems rises.

- Innovations in PE Resin Technology: Advances in manufacturing processes enhance product quality and performance.

- Environmental Regulations: Stricter regulations compel industries to adopt sustainable practices, including the use of recyclable materials.

Challenges in the Market

- Competition and Pricing Pressures: The influx of new players intensifies competition, leading to pricing wars.

- Supply Chain Disruptions: Global events can disrupt supply chains, affecting production and delivery timelines.

- Regulatory Hurdles: Navigating complex regulations can be daunting for companies aiming to innovate.

FAQs

What is it Resin used for? It Resin is primarily used in the production of pipes for water supply, gas distribution, and drainage systems.

How does the demand for PE Pipe Resin vary by region? Demand varies due to factors like infrastructure development, environmental regulations, and industrial needs specific to each region.

Who are the top competitors in the PE Pipe Resin market? Key competitors include LyondellBasell, DuPont, Borealis, and SABIC, each with distinct strategies and market approaches.

What test procedures must PE pipes conform to under this specification?

Testing Requirements for PE Pipes

Under this specification, PE pipes must undergo various test procedures to ensure they meet quality and durability standards. The evaluation process includes:

- Workmanship Inspection: Inspectors carefully examine the pipes to confirm they exhibit flawless construction and finish.

- Dimensional Analysis: Measurements are checked to ensure they adhere to strict dimensional criteria.

- Sustained Pressure Testing: They subject the pipes to pressure tests at both ambient and elevated temperatures to validate their performance under different conditions.

- Hydrostatic Burst Testing: This test assesses the pipe’s ability to withstand sudden internal pressure.

- Tensile Strength at Yield: The material strength is evaluated to gauge how much stress the pipe can bear before deforming.

- Environmental Stress Cracking: They test the pipes for resistance to cracking under environmental stresses to ensure long-term reliability.

These comprehensive assessments are vital to certify that PE pipes not only meet industry standards but are also safe and effective for their intended applications.

What criteria are included for classifying PE plastic pipe materials?

When classifying PE plastic pipe materials, several key criteria are considered. These include the pipe’s density, pressure capacity, and thermal resistance. Additionally, factors such as environmental stress crack resistance and material flexibility are also assessed.

The classification system provides a comprehensive framework for identifying and categorizing different types of PE plastic pipes. This system helps ensure the pipes meet specific industry standards for performance and longevity. By understanding these criteria, you can make informed decisions when selecting the right PE plastic pipes for your needs.

What safety concerns should users of this specification be aware of?

Understanding Safety Concerns in This Specification

When you use the test methods outlined in Section 7 of this specification, you must be aware that the methods do not explicitly address all potential safety hazards. Here’s a clearer breakdown of what you should consider:

- Self-Assessment Responsibility: Users are responsible for identifying and managing safety, health, and environmental risks. Before utilizing the test methods, ensure you are aware of any potential hazards specific to your environment.

- Establish Safe Practices: Develop and implement safety protocols tailored to your specific situation. This includes ensuring the use of appropriate personal protective equipment (PPE) and understanding hazardous materials involved in the tests.

- Regulatory Compliance: Determine which regulatory limitations apply to your use of these test methods. Make sure that your practices comply with relevant local, national, or international regulations.

- Environmental Considerations: Consider the environmental impact of conducting these tests and take steps to minimize any potential harm.

By actively addressing these areas, you can better manage the associated risks while adhering to this specification.

What methods are used for marking PE plastic pipes?

Methods for Marking PE Plastic Pipes

Several standardized methods mark polyethylene (PE) plastic pipes to ensure identification and compliance. Here’s a breakdown of the most common techniques used:

- Ink Jet Printing

This method utilizes high-speed technology to print essential information directly onto the pipe’s surface. It allows for clear, precise marking of details such as size, pressure rating, and manufacturing data. Ink jet printing is favored for its speed and cost-effectiveness. - Hot Foil Stamping

Hot foil stamping involves pressing hot foils onto the pipe, transferring ink through heat and pressure. This technique ensures durable and legible marking, suitable for environments where the pipe may be subject to wear and tear. - Engraving

For a permanent solution, engraving can be used to etch information into the pipe material. This method provides long-lasting marks that withstand various environmental conditions, though it can be more time-consuming and costly compared to other methods. - Laser Marking

Using high-precision laser technology, this method applies labels without any contact. Laser marking ensures accuracy and durability, making it an ideal choice for high-volume manufacturing where reliability is paramount.

These marking methods are crucial for identification, quality control, and ensuring that the pipes meet industry standards. Each method offers different benefits, allowing manufacturers to select the appropriate technique based on their specific needs and production requirements.

What are the standard units of measurement used in this specification?

In this specification, the primary units of measurement are inch-pound units. These serve as the standard for all calculations and references. Although the text includes metric conversions to SI units, it provides them solely for informational purposes, and they do not hold the same standard status as the inch-pound units.

How was this international standard developed in accordance with recognized principles on standardization?

Development of the International Standard: A Compliance with Global Criteria

The creation of this international standard followed a methodology aligned with globally acknowledged standardization principles. Best practices designed to foster uniformity and fairness in global trade root these principles.

Guided by Global Agreements

Frameworks established through international agreements, notably those outlined by the World Trade Organization (WTO), shaped the guidelines. Specifically, the standard adheres to the practices highlighted in the WTO‘s Decision on Principles for the Development of International Standards, Guides, and Recommendations.

Technical Integrity and Trade Facilitation

By adhering to these principles, the standard ensures technical integrity, boosts safety benchmarks, and mitigates trade barriers. It reflects a collaborative effort to harmonize standards internationally, thus facilitating smoother trade operations and enhancing product quality across borders.

Ensuring Consistency and Fair Practice

These recognized principles emphasize consensus, transparency, and non-discriminatory practices in the standard’s development process. This ensures that the resulting standards are consistent, practical, and equitable for all stakeholders involved, from manufacturers to consumers.

In summary, the standard’s development is a testament to meticulous adherence to global protocols, enhancing its credibility and applicability in international markets.

What are the requirements for polyethylene compounds and PE plastic pipe according to this specification?

Requirements for Polyethylene Compounds and PE Plastic Pipe

When it comes to polyethylene (PE) pipe specifications, there are several critical requirements to ensure both performance and safety:

- Pipe Dimensions:

Manufacturers must produce PE pipes in thermoplastic pipe dimension ratios based on outside diameters ranging from IPS 1/2 to 3. These dimensions cater to both non-pressure and pressure-rated water applications. - Material Composition:

Only specified polyethylene compounds should be used. These compounds must meet stringent criteria to ensure the durability and reliability of the pipe. - Nomenclature System:

A systematic approach to naming categorizes PE plastic pipe, facilitating easy identification and specification. - Performance Tests:

Pipes must undergo rigorous testing for:- Sustained Pressure: Ensuring they can endure prolonged pressure without failure.

- Burst Pressure: Assessing the maximum pressure the pipe can withstand before bursting.

- Workmanship and Dimensions:

Manufacturers must observe high standards to craft the pipes with precision and ensure they meet specified dimension tolerances. - Marking Methods:

The specification outlines proper marking techniques to trace each pipe back to its specifications and manufacturing details.

Special Considerations for Potable Water and Oxidizing Disinfectants

For pipes designated for potable water or fluids containing oxidizing disinfectants like hypochlorous acid or chloramines:

- PE Compound Special Requirements:

There are specific requirements for polyethylene compounds to ensure resistance to these chemicals. - Dimension Ratio (DR) Limitations:

Special dimension ratio limitations apply to manage stress and prevent degradation in such environments.

These criteria ensure that PE pipes are not only functional but also meet health and safety standards when used in critical applications.

What special requirements are there for PE compounds used with oxidizing disinfectants in the distribution of potable water?

When it comes to using polyethylene (PE) compounds in pipes for transporting potable water with oxidizing disinfectants, there are specific standards to meet. These guidelines ensure the safety and efficiency of the water supply.

Key Requirements:

- PE Compound Standards: The compounds must have particular properties tailored to resist the effects of oxidizing disinfectants, like hypochlorous acid and chloramines. These chemicals can affect the integrity of the PE material over time.

- Dimensional Ratio (DR) Limitations: There are constraints on the dimensional ratio of the pipes. These limitations ensure that the pipe wall thickness is adequate to withstand internal pressures and the potentially corrosive nature of the disinfectants.

By adhering to these specifications, the pipes remain durable and effective in delivering clean, safe drinking water.

What is the standard specification for polyethylene (PE) plastic pipe based on controlled outside diameter?

Understanding the Standard Specification for Polyethylene (PE) Plastic Pipe

The standard specification for polyethylene (PE) plastic pipes provides guidelines and requirements for pipes made with thermoplastic dimension ratios, based on controlled outside diameter. These specifications ensure that manufacturers pressure-rate the pipes for applications such as transporting water, industrial liquids, effluents, slurries, and sewage.

Key Aspects of the Specification

- Material Classification and Nomenclature: The standard includes detailed criteria for classifying both PE plastic pipe materials and the pipes themselves. This ensures consistency and quality across the industry.

- Evaluation Procedures: PE pipes must undergo rigorous testing to meet the standards. Test procedures evaluate aspects like workmanship, dimensions, tensile strength at yield, and resistance to environmental stress cracking.

- Performance Requirements: Specifications also include requirements for sustained pressure at both ambient and elevated temperatures, as well as hydrostatic burst pressure.

These guidelines ensure that PE plastic pipes are reliable, durable, and fit for a wide range of applications. By adhering to these standards, manufacturers and users can be confident in the quality and performance of their PE piping solutions.

What types of fluids can be transported using polyethylene (PE) plastic pipes under this specification?

What is it Resin used for?

It Resin is primarily used in the production of pipes for water supply, gas distribution, and drainage systems. These versatile pipes are capable of transporting a variety of fluids, making them suitable for numerous applications.

- Water: Safely transport potable and non-potable water across different distances.

- Industrial Process Liquids: Ideal for handling various industrial fluids, ensuring efficient and secure transportation.

- Effluents and Slurries: Designed to manage waste and byproducts from industrial processes, these pipes provide reliable conveyance.

- Municipal Sewage: Essential for municipal infrastructure, they effectively carry sewage and other waste materials.