Introduction

How their advanced additives are optimizing the performance of PE pipes. PE Pipe not only promises enhanced performance and durability but also underscores the growing trend towards more sophisticated and sustainable solutions in the plastic industry. This article delves into how Greenmantra’s polymer additives work, their benefits, and the broader implications for the it market.

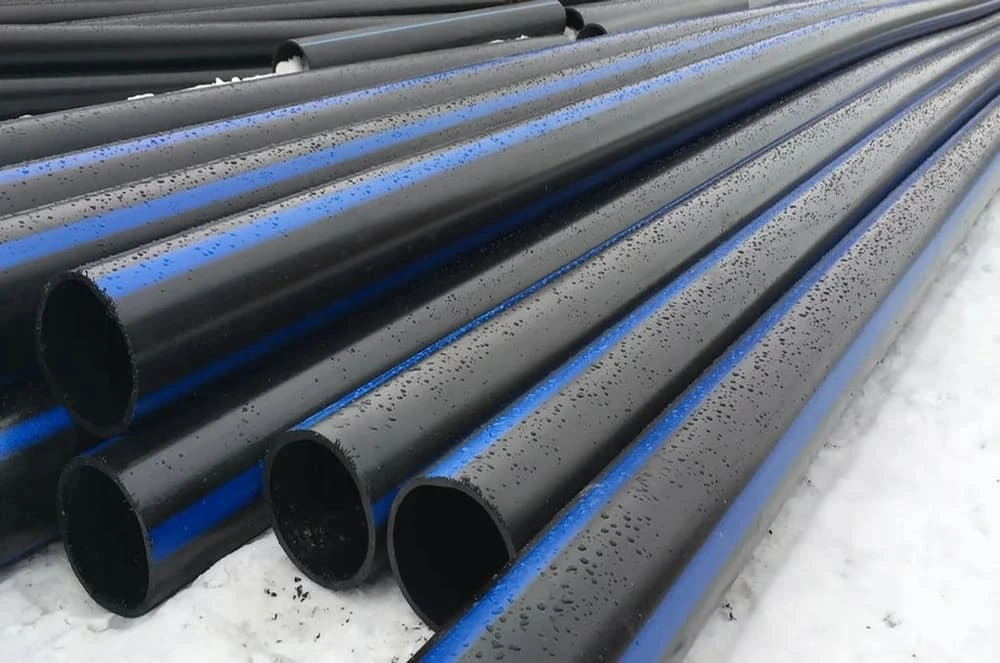

Understanding PE Pipes

Advantages of PE Pipes

PE pipes offer several benefits:

- Durability: Resistant to corrosion, chemicals, and impact.

- Flexibility: Can be easily bent and installed in various configurations.

- Cost-Effectiveness: Lower material and installation costs compared to traditional materials.

The Role of Polymer Additives

What Are Polymer Additives?

Polymer additives are substances added to polymer resins to enhance their properties. These additives can improve various aspects of the polymer, such as its strength, flexibility, and resistance to environmental factors.

Types of Polymer Additives

Common types of polymer additives include:

- Stabilizers: Protect polymers from degradation due to heat, light, or oxidation.

- Plasticizers: Increase flexibility and reduce brittleness.

- Reinforcements: Add strength and impact resistance.

Introduction to Greenmantra

Greenmantra is a pioneer in developing advanced polymer additives that are designed to optimize the performance of various plastic products, including PE pipes. Their additives are known for their innovative approach and commitment to sustainability.

How Greenmantra’s Additives Work

- Enhance Mechanical Properties: Improve the strength and durability of PE pipes.

- Increase Environmental Resistance: Enhance the pipes’ resistance to environmental stressors such as UV radiation and extreme temperatures.

- Improve Processability: Facilitate easier and more efficient manufacturing processes.

Benefits of Using Greenmantra’s Additives in PE Pipes

Improved Durability

Greenmantra’s additives contribute to increased durability by:

- Strengthening the Pipe: Enhanced mechanical properties result in pipes that can withstand higher pressure and more significant impacts.

- Extending Lifespan: Increased resistance to environmental factors ensures a longer service life.

Enhanced Flexibility

The additives improve the flexibility of PE pipes, making them easier to install and adapt to various configurations, which can be particularly beneficial in complex or constrained environments.

Better Environmental Resistance

Greenmantra’s additives offer superior protection against UV radiation and temperature fluctuations, reducing the risk of pipe degradation and ensuring reliable performance in diverse conditions.

Case Studies: Success Stories

Case Study 1: Municipal Water Supply

In a recent project involving a municipal water supply system, the use of Greenmantra’s additives resulted in:

- Increased Pipe Longevity: The additives enhanced the pipes’ resistance to environmental stress, extending their operational life.

- Reduced Maintenance Costs: Improved durability led to fewer repairs and replacements, saving costs for the municipality.

Case Study 2: Industrial Application

For an industrial client dealing with aggressive chemicals, Greenmantra’s additives provided:

- Enhanced Chemical Resistance: The pipes maintained their integrity and performance despite exposure to harsh chemicals.

- Improved Safety: The increased strength and durability of the pipes reduced the risk of leaks and failures.

Industry Implications

Greenmantra’s advancements in polymer additives are likely to influence the it market in several ways:

- Increased Adoption: Enhanced performance properties may drive greater adoption of PE pipes in various applications.

- Competitive Edge: Manufacturers using these additives can differentiate their products by offering superior durability and flexibility.

Sustainability and Innovation

The use of advanced polymer additives aligns with broader industry trends towards sustainability and innovation:

- Reduced Environmental Impact: By extending the lifespan of PE pipes, Greenmantra’s additives contribute to reduced waste and lower environmental impact.

- Technological Advancements: Ongoing innovation in additives supports the development of more advanced and efficient plastic products.

Conclusion

By enhancing the mechanical properties, flexibility, and environmental resistance of these pipes, Greenmantra is setting a new standard for performance and durability in the industry. This innovation not only benefits manufacturers and end-users but also supports broader goals of sustainability and efficiency in plastic production.

FAQs

What are the main benefits of Greenmantra’s polymer additives for PE pipes?

Greenmantra’s additives improve the durability, flexibility, and environmental resistance of PE pipes, leading to longer service life and better performance.

How do polymer additives enhance the performance of PE pipes?

Additives can strengthen the pipes, increase their flexibility, and protect them from environmental stressors such as UV radiation and extreme temperatures.

Can you provide examples of successful applications of Greenmantra’s additives?

Yes, Greenmantra’s additives have been successfully used in municipal water supply systems and industrial applications, resulting in increased pipe longevity and reduced maintenance costs.

How do Greenmantra’s additives contribute to sustainability?

By extending the lifespan of PE pipes and reducing the need for replacements, Greenmantra’s additives help minimize waste and environmental impact.

What impact might Greenmantra’s innovations have on the plastic pipe industry?

Greenmantra’s innovations are likely to drive increased adoption of PE pipes, improve product differentiation, and support broader trends in sustainability and technological advancement.