When it comes to Reverse Osmosis (RO) plants, selecting the right materials is crucial for efficiency and durability. PEX pipes and fittings have become increasingly popular in this sector. This guide will explore the benefits, applications, and installation tips for using PEX in RO systems.

1. Introduction

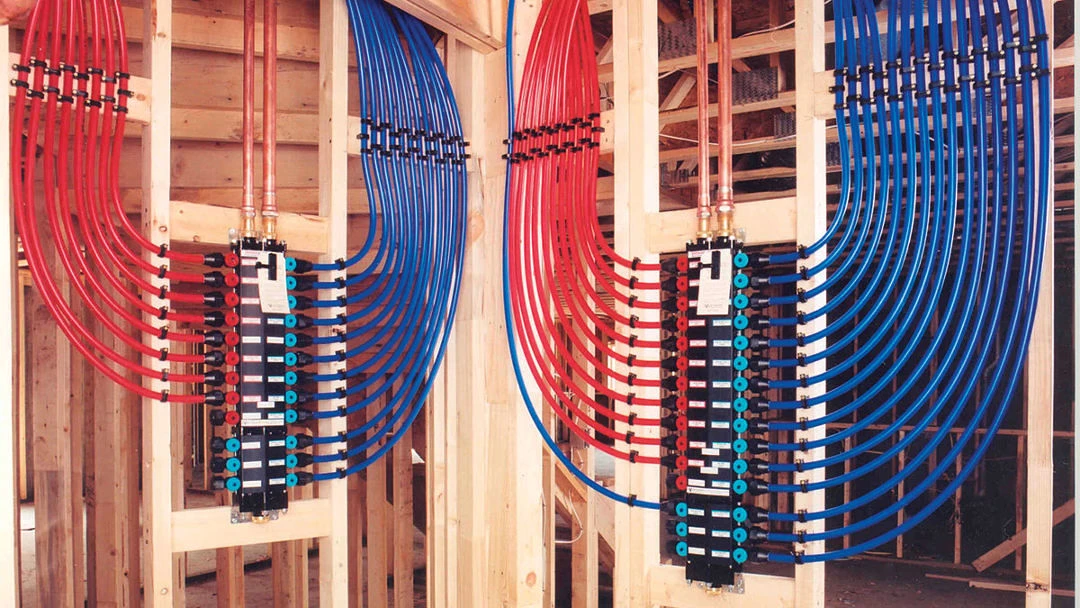

Using PEX pipes and fittings in RO plants offers a range of advantages, from flexibility to corrosion resistance. This guide will help you understand how PEX can enhance the performance and reliability of your RO systems.

2. What is PEX?

PEX is a flexible plastic piping material that is resistant to temperature extremes and chemical reactions. It is commonly used in plumbing, heating, and filtration applications, making it suitable for RO systems.

3. Advantages of PEX in RO Plants

- Corrosion Resistance: Unlike metal pipes, PEX will not corrode, ensuring a longer lifespan and cleaner water.

- Flexibility: PEX can bend easily, allowing for straightforward installations around obstacles.

- Reduced Leaks: With fewer joints and connections needed, the likelihood of leaks decreases significantly.

- Cost-Effectiveness: PEX is generally more affordable than traditional piping materials, reducing overall project costs.

4. Applications of PEX in RO Systems

PEX pipes and fittings are used in various parts of an RO plant, including:

- Feed Water Lines: Transporting untreated water to the RO membranes.

- Product Water Lines: Carrying purified water to storage or distribution systems.

- Brine Lines: Disposing of concentrated waste from the RO process.

5. Types of PEX Pipes and Fittings

- PEX-A: Highly flexible and easy to work with, ideal for tight spaces.

- PEX-B: More affordable and widely used, suitable for standard applications.

- Crimp Fittings: Commonly used to secure PEX connections with metal rings.

- Push-Fit Fittings: Allow for quick connections without tools, simplifying installation.

6. Installation Guidelines for PEX in RO Plants

6.1 Tools Needed

- PEX cutter

- Crimping tool or push-fit tool

- Measuring tape

- Deburring tool

6.2 Step-by-Step Installation

- Plan the Layout: Map out the piping route for optimal efficiency.

- Measure and Cut: Cut the PEX pipe to the required lengths.

- Deburr: Smooth out any rough edges to prevent damage to fittings.

- Attach Fittings: Insert the fittings into the pipe.

- Secure Connections: Use a crimping tool or push-fit tool to ensure a tight seal.

- Check for Leaks: Turn on the system and inspect for leaks before finalizing installation.

7. Maintenance of PEX in RO Systems

Regular maintenance is crucial for ensuring optimal performance:

- Inspect for Leaks: Periodically check connections and pipes for signs of leakage.

- Clean Filters: Maintain RO filters regularly to ensure efficient operation.

- Monitor Pressure: Keep an eye on system pressure to identify any blockages or issues.

8. Common Challenges and Solutions

- Expansion and Contraction: PEX can expand or contract with temperature changes. Use appropriate supports and fittings to accommodate this.

- UV Sensitivity: While PEX is resistant to many chemicals, prolonged exposure to sunlight can damage it. Ensure that any exposed sections are adequately covered.

9. Conclusion

Using PEX pipes and fittings in RO plants offers significant advantages, including flexibility, durability, and cost savings. Understanding how to properly implement and maintain PEX in your RO system can enhance efficiency and extend its lifespan.

10. FAQs

1. Can PEX be used for hot water in RO systems?

Yes, PEX can handle hot water up to 200°F (93°C), making it suitable for various applications.

2. How long does PEX last in RO applications?

When properly installed and maintained, PEX can last over 50 years.

3. Is PEX safe for drinking water?

Yes, PEX meets all health standards for potable water systems and is safe for drinking water.

4. Can I connect PEX to metal pipes?

Yes, you can use appropriate fittings to connect PEX to copper or PVC pipes.

5. What should I do if I notice a leak in my PEX system?

Inspect the connection points, tighten fittings if necessary, or replace damaged sections of pipe.

When it comes to Reverse Osmosis (RO) plants, selecting the right materials is crucial for efficiency and durability. PEX pipes and fittings have become increasingly popular in this sector. This guide will explore the benefits, applications, and installation tips for using PEX in RO systems.