In today’s world, the safety and sustainability of materials used in construction and plumbing are more critical than ever. One significant concern for many industries is the presence of PFAS (Per- and Polyfluoroalkyl Substances) in products. As you consider HDPE pipes and fittings for your projects, you may wonder: are they PFAS free? Let’s delve into this topic and understand the implications for your plumbing needs.

What Are HDPE Pipes and Fittings?

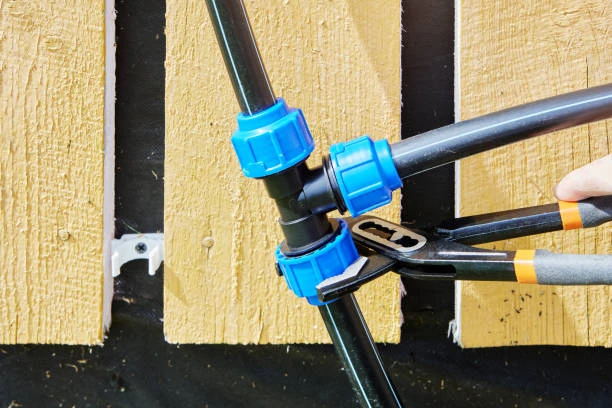

High-Density Polyethylene (HDPE) pipes and fittings are widely used in various applications, including water supply, sewage systems, and industrial processes. Made from a thermoplastic polymer, HDPE offers numerous advantages, such as:

- Durability: HDPE pipes are resistant to corrosion and can withstand harsh environmental conditions.

- Flexibility: They are flexible enough to accommodate different terrains, making them ideal for various installations.

- Cost-Effectiveness: The longevity of HDPE pipes results in lower maintenance and replacement costs over time.

Understanding PFAS

1. What Are PFAS?

Commonly found in products like non-stick cookware, water-repellent fabrics, and firefighting foam, PFAS can persist in the environment and accumulate in the human body.

2. Health Concerns Associated with PFAS

Research suggests that exposure to PFAS may lead to several health issues, including:

- Hormonal Disruption: PFAS can interfere with hormone levels and endocrine functions.

- Immune System Effects: They may weaken the immune response, making individuals more susceptible to diseases.

- Increased Cancer Risk: Some studies have linked PFAS exposure to certain types of cancer.

Are HDPE Pipes and Fittings PFAS Free?

1. Manufacturing Standards

Most reputable manufacturers of HDPE pipes and fittings produce their products without PFAS. They adhere to strict industry standards and regulations, ensuring that their materials are safe for use in drinking water systems and other applications. However, it’s essential to verify the specifications provided by the manufacturer.

2. Certifications to Look For

When selecting HDPE pipes and fittings, look for products that are certified by recognized organizations, such as:

- NSF/ANSI 61: This certification indicates that the product meets safety standards for drinking water system components.

- ASTM Standards: Compliance with ASTM standards ensures that the materials used in production meet safety and quality benchmarks.

Benefits of Using PFAS-Free HDPE Pipes and Fitting

1. Safety and Health

Choosing PFAS-free HDPE pipes and fitting significantly reduces the risk of exposure to harmful chemicals. This choice is particularly vital for drinking water systems, where safety is paramount.

2. Environmental Responsibility

Using PFAS-free materials aligns with sustainable practices. As industries move towards greener solutions, opting for safe materials contributes to reducing environmental pollution.

3. Regulatory Compliance

Many regions have implemented regulations restricting the use of PFAS in construction materials. By selecting HDPE pipes and fittings that are PFAS-free, you ensure compliance with current and future regulations.

How to Ensure Your HDPE Pipes and Fittings Are PFAS Free

1. Research Manufacturers

Before purchasing HDPE pipes and fittings, research the manufacturers. Look for companies that provide transparency about their materials and manufacturing processes.

2. Request Documentation

Don’t hesitate to request documentation regarding the materials used in the production of HDPE pipes and fittings. Certifications and test results can provide peace of mind regarding PFAS content.

3. Consult Industry Experts

If you’re unsure about the safety of specific products, consult industry experts or professionals in plumbing and construction. They can offer insights and recommendations on the best materials for your needs.

Conclusion

In summary, while most reputable manufacturers of HDPE pipes and fittings strive to produce PFAS-free products, it’s essential to conduct your due diligence. By understanding the implications of PFAS, you can make informed decisions that prioritize safety, health, and environmental responsibility. Always choose products that meet recognized safety standards and consult with experts to ensure you’re selecting the best options for your projects.

FAQs

1. What are HDPE pipes and fittings used for?

HDPE pipes and fittings are commonly used for water supply, sewage systems, and industrial applications due to their durability and flexibility.

2. Why is it important for HDPE pipes to be PFAS-free?

Being PFAS-free minimizes health risks associated with chemical exposure, particularly in drinking water systems.

3. How can I verify if a manufacturer’s HDPE products are PFAS-free?

You can verify this by checking for certifications, requesting documentation, and researching the manufacturer’s practices.

4. What are the health risks associated with PFAS exposure?

PFAS exposure has been linked to hormonal disruption, weakened immune response, and increased cancer risk.

5. Are there regulations concerning PFAS in construction materials?

Yes, many regions have implemented regulations that restrict the use of PFAS in construction materials to promote safety and environmental responsibility.

If you have further questions or need additional information, feel free to reach out!