Introduction

FosRich, a leading player in the manufacturing and distribution of high-quality piping solutions, is focusing its strategic efforts on expanding its portfolio of HDPE fittings pipes. The company aims to make HDPE (High-Density Polyethylene) fittings its largest business line within the next two years. As industries across the world seek durable, cost-effective, and sustainable piping solutions, HDPE pipes and fittings are emerging as the material of choice for many applications, including water distribution, gas transport, and industrial infrastructure. In this article, we will explore the growing demand for HDPE fittings, the key advantages they offer, and why FosRich has placed its bets on this business line for future growth.

What Are HDPE Fittings Pipes?

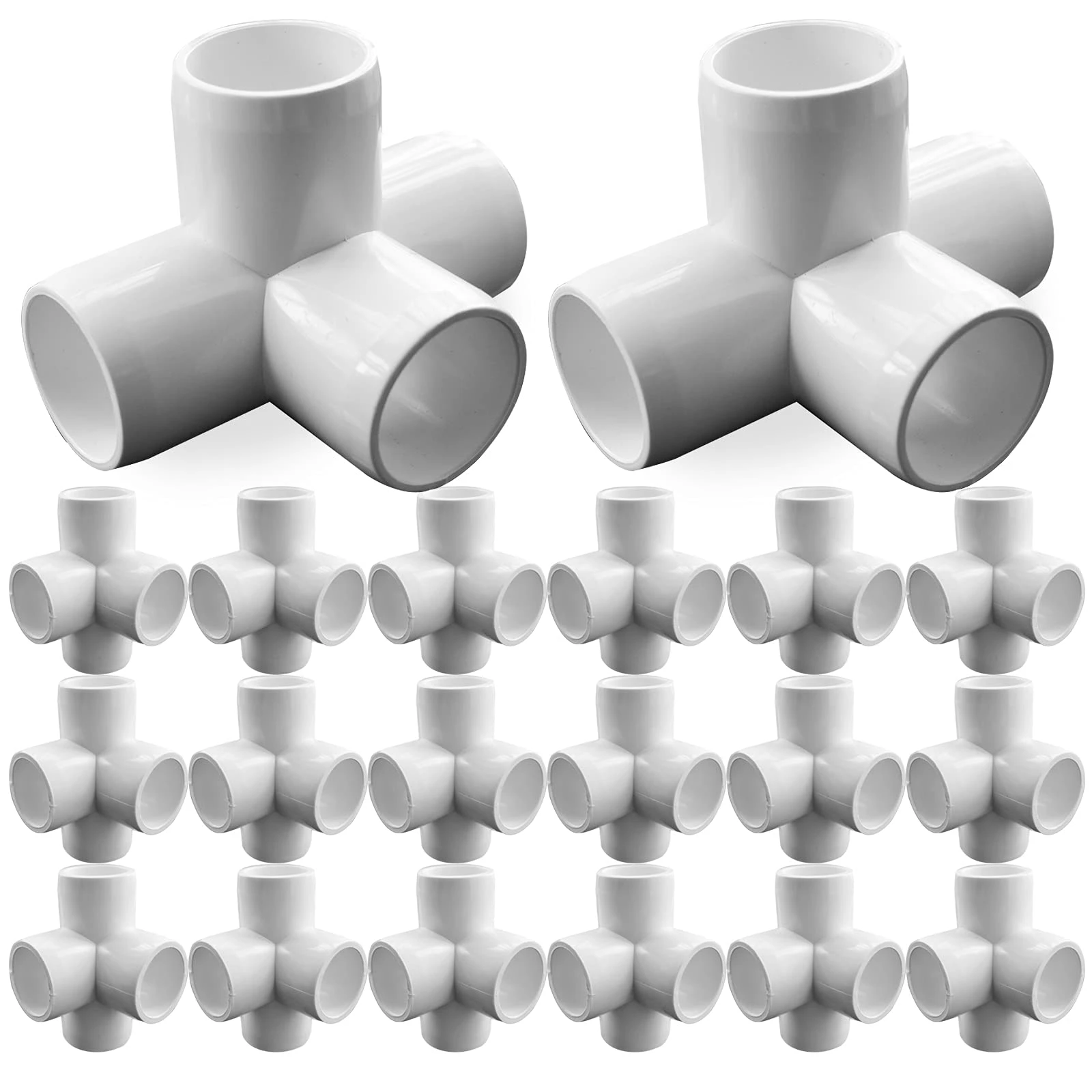

HDPE fittings pipes consist of high-density polyethylene, a type of thermoplastic polymer known for its strength, flexibility, and resistance to various chemicals and environmental factors. People commonly use these pipes in water distribution systems, gas pipelines, sewage systems, and industrial applications. HDPE fittings are essential components that help join, change direction, and secure sections of HDPE pipes. Common types of HDPE fittings include elbows, tees, couplings, adapters, and flanges.

Why FosRich is Focusing on HDPE Fittings Pipes

1. Market Demand for Durable Solutions

One of the primary reasons FosRich is emphasizing HDPE fittings pipes is the increasing demand for durable, long-lasting piping systems. HDPE pipes and fittings are known for their remarkable durability, able to withstand high pressures and resist corrosion, UV rays, and chemicals. As infrastructure projects continue to expand globally, the need for reliable piping solutions grows, and HDPE is becoming the preferred choice in various sectors.

2. Environmental Sustainability

As sustainability becomes a core consideration in infrastructure projects, HDPE pipes are gaining popularity due to their eco-friendly properties. They are highly recyclable, making them an environmentally responsible choice. Additionally, HDPE pipes are known to have a longer service life compared to traditional materials, reducing the need for replacements and maintenance. FosRich’s decision to prioritize HDPE fittings aligns with the global trend of adopting sustainable materials in the construction and infrastructure industries.

3. Cost-Effectiveness

The cost-effectiveness of HDPE fittings is another factor driving their increased adoption. HDPE is generally cheaper than alternative materials like steel and copper, both in terms of initial material costs and long-term maintenance. HDPE’s ability to resist corrosion also reduces the risk of pipe failure, which can lead to costly repairs and downtime. As a result, industries that rely on piping systems, such as water treatment plants, construction, and agriculture, are making the switch to HDPE for its economic benefits.

4. Versatility in Applications

The versatility of HDPE fittings is another key reason FosRich is looking to capitalize on this market. HDPE pipes are used in a wide variety of applications, including municipal water systems, sewage lines, irrigation, and industrial applications. The ability to serve such a broad range of industries positions HDPE fittings as a crucial component in the future of infrastructure development. FosRich aims to capture a larger market share by producing a diverse range of HDPE fittings tailored to different needs.

5. Technological Advancements

Advancements in manufacturing technologies have made HDPE fittings more efficient, reliable, and easier to produce. FosRich is capitalizing on these technological innovations, ensuring that it can meet the growing demand for high-quality HDPE pipes and fittings. By investing in cutting-edge production processes, the company is positioning itself as a leader in the HDPE fittings market.

Key Benefits of HDPE Fittings Pipes

1. Durability and Longevity

HDPE fittings are extremely durable, with a service life that can exceed 50 years. They are resistant to corrosion, abrasion, and chemical reactions, making them ideal for use in harsh environments. This long lifespan reduces the need for frequent replacements, providing both cost savings and peace of mind for businesses and municipalities.

2. Flexibility and Ease of Installation

One of the most significant advantages of HDPE fittings is their flexibility. These fittings can be bent to fit around corners or obstacles, reducing the need for additional joints and connections. This flexibility makes installation easier and faster, resulting in lower labor costs and a more efficient installation process.

3. Corrosion Resistance

Unlike metal piping systems that are susceptible to rust and corrosion over time, HDPE fittings are resistant to these issues. This makes them ideal for use in water and sewage systems, where exposure to moisture and chemicals is common. The ability to resist corrosion ensures that HDPE pipes and fittings have a longer lifespan and require minimal maintenance.

4. Leak-Free Joints

HDPE fittings are designed to create leak-free joints. This is especially important in applications like water distribution systems, where leaks can result in significant water loss and costly repairs. HDPE fittings are typically fused together using heat fusion methods, creating strong, leak-proof joints that enhance the overall performance and reliability of the piping system.

5. Environmental Benefits

HDPE is 100% recyclable, making it an environmentally friendly option for piping systems. The material can be reused to create new pipes, reducing waste and contributing to a circular economy. Additionally, the long lifespan of HDPE pipes reduces the frequency of replacements, which further minimizes environmental impact.

How FosRich Plans to Capitalize on the HDPE Fittings Market

FosRich has recognized the growing potential of the HDPE fittings market and is focused on strengthening its position in this sector. Here are some strategies the company is implementing to capture a larger market share:

1. Expanding Production Capabilities

To meet the growing demand for HDPE fittings, FosRich is investing in expanding its production capacity. This includes upgrading existing manufacturing facilities and incorporating advanced technology to improve production efficiency and product quality.

2. Product Innovation

FosRich is continuously developing new and innovative HDPE fittings that cater to specific industry needs. The company focuses its R&D efforts on creating high-performance fittings that can withstand the most challenging conditions, making them suitable for use in a variety of industries.

3. Strengthening Distribution Channels

To reach a broader customer base, FosRich is enhancing its distribution network. The company is forging partnerships with key distributors and suppliers in both domestic and international markets. This expansion of its distribution channels will ensure that FosRich’s HDPE fittings are available to a wide range of customers across multiple regions.

4. Sustainable Manufacturing Practices

FosRich is committed to sustainability in its manufacturing processes. The company is implementing eco-friendly production techniques that reduce energy consumption and waste. This focus on sustainability is not only good for the environment but also aligns with global trends in green construction and infrastructure development.

Conclusion

FosRich’s strategic focus on HDPE fittings pipes is a smart move in response to the growing demand for durable, cost-effective, and sustainable piping solutions. With advancements in technology, increased environmental awareness, and the need for reliable infrastructure, HDPE fittings will play a critical role in shaping the future of the global piping industry. FosRich’s investments in expanding production capabilities, product innovation, and sustainability will help the company capitalize on this growing market, positioning it as a key player in the HDPE fittings industry in the years to come.

FAQs

1. What are HDPE fittings pipes?

HDPE fittings connect, secure, and seal sections of HDPE pipes in various applications, including water distribution, sewage systems, and industrial infrastructure, and they use high-density polyethylene.

2. Why are HDPE fittings pipes becoming popular?

HDPE fittings are gaining popularity due to their durability, flexibility, resistance to corrosion, cost-effectiveness, and sustainability, making them ideal for long-term infrastructure projects.

3. What industries use HDPE fittings?

HDPE fittings are used in various industries, including water distribution, agriculture, construction, gas transport, and sewage systems.

4. How long do HDPE fittings last?

HDPE fittings have a long lifespan, typically lasting 50 years or more, thanks to their resistance to corrosion, chemicals, and environmental factors.

5. Are HDPE fittings eco-friendly?

Yes, HDPE fittings are 100% recyclable and have a longer lifespan than traditional materials, reducing the need for frequent replacements and contributing to sustainability.