Introduction

HDPE pipe and fittings have become essential in various industries due to their strength, durability, and resistance to corrosion and chemicals. As the global demand for efficient and sustainable piping solutions increases, the HDPE pipe and fittings market will experience significant growth. This report provides an overview of the HDPE pipe and fittings market for 2024, highlighting key market drivers, applications, trends, and regional analysis.

What are HDPE Pipes and Fittings?

HDPE pipes and fittings are made from a thermoplastic polymer known for its high strength-to-density ratio. People commonly use these products to transport water, gas, and other fluids in residential, commercial, and industrial settings. Their resistance to chemical degradation, flexibility, and long lifespan make them an ideal choice for a wide range of applications.

Key Benefits of HDPE Pipes and Fittings

1. Durability and Longevity

HDPE pipes are designed to withstand extreme weather conditions, high pressure, and environmental stress. They have an expected lifespan of over 50 years, making them a reliable choice for long-term infrastructure.

2. Chemical and Corrosion Resistance

Unlike metal pipes, HDPE pipes do not corrode or rust. They are also resistant to a wide range of chemicals, making them suitable for various industrial applications.

3. Environmental Sustainability

HDPE is recyclable, which reduces environmental impact. Additionally, the low carbon footprint of HDPE production and minimal maintenance requirements support sustainable practices.

4. Cost Efficiency

Although the initial investment in HDPE piping may be higher than traditional materials, their minimal maintenance needs and extended lifespan contribute to significant long-term cost savings.

5. Flexibility and Adaptability

HDPE pipes are flexible, allowing them to be installed in challenging terrains without compromising structural integrity. This flexibility also reduces the risk of breaks and leaks.

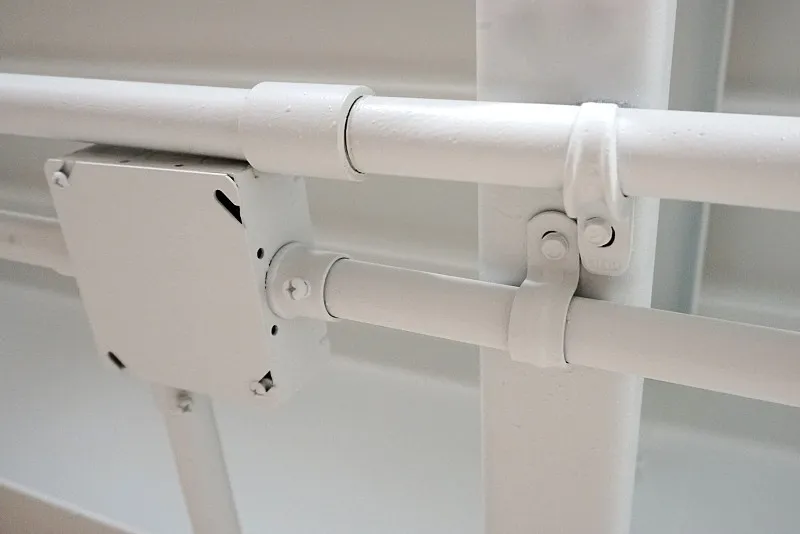

Types of HDPE Fittings

HDPE fittings come in various forms to accommodate different piping configurations. Some common types include:

1. Couplers

Used to join two pipes of the same diameter, couplers provide a seamless, leak-proof connection in HDPE piping systems.

2. Tees

Tees allow for branching connections in a pipeline, making them essential for distributing water or gas to multiple locations.

3. Elbows

Available in 45° and 90° angles, elbows redirect flow within a piping system. They are commonly used in water distribution systems.

4. Reducers

Reducers are used to connect pipes of different diameters, allowing for customized flow adjustments.

5. End Caps

End caps are fitted at the end of pipes to prevent leaks and ensure system security.

Applications of HDPE Pipes and Fittings

HDPE pipes and fittings are versatile and serve various industries. Key applications include:

1. Water Distribution

HDPE pipes are widely used in municipal water distribution systems due to their leak-proof and corrosion-resistant properties.

2. Gas Distribution

HDPE’s ability to withstand high pressure makes it suitable for gas distribution networks, where safety and durability are paramount.

3. Agricultural Irrigation

Agricultural irrigation relies on HDPE piping for its flexibility, chemical resistance, and capacity to deliver water over large areas effectively.

4. Industrial Applications

In industrial settings, HDPE pipes transport chemicals, wastewater, and other materials, offering durability and resistance to corrosive substances.

5. Sewage and Drainage Systems

HDPE pipes are used in sewage and drainage systems, where their long lifespan and resistance to contaminants are essential.

Market Trends Driving the HDPE Pipe and Fittings Market

1. Growing Infrastructure Development

With governments and private companies investing in infrastructure, the demand for HDPE piping solutions rises for projects focused on water and gas supply, sewage, and industrial systems.

2. Rising Emphasis on Sustainability

The global focus on sustainability is pushing demand for recyclable, environmentally friendly materials like HDPE. The material’s recyclability and low environmental impact align with green building initiatives worldwide.

3. Urbanization and Population Growth

Increasing urbanization requires the expansion of water and sewage systems. HDPE pipes, with their durability and low maintenance needs, are ideal for these high-demand urban applications.

4. Technological Advancements in HDPE Manufacturing

Innovations in HDPE production, such as improved welding techniques and higher-pressure grades, are enhancing the material’s versatility, reliability, and cost-effectiveness.

5. Expansion of Agricultural Sector

As the global population grows, so does the need for effective irrigation systems. HDPE pipe and fittings are essential for modern irrigation systems, providing efficient and sustainable water management.

Challenges in the HDPE Pipe and Fittings Market

Despite the market’s growth, some challenges affect HDPE adoption:

1. Fluctuating Raw Material Prices

HDPE is a petroleum-based product, and fluctuations in oil prices can influence the cost of HDPE pipes and fittings, impacting affordability.

2. Competition from Alternative Materials

Materials like PVC, metal, and concrete offer different advantages and may compete with HDPE in certain applications, particularly when lower-pressure systems are involved.

3. Installation and Maintenance Challenges

HDPE installation requires specialized welding techniques, which may increase costs and limit adoption in regions with fewer skilled professionals.

4. Environmental Concerns Related to Plastic Usage

While HDPE is recyclable, the environmental impact of plastic remains a concern, leading some stakeholders to seek alternative materials where possible.

Regional Analysis of the HDPE Pipe and Fittings Market

The HDPE market shows different growth rates across regions due to variations in infrastructure, economic development, and industry focus.

1. North America

The North American HDPE market is mature, with high adoption in water and gas distribution systems. Government support for infrastructure upgrades is expected to drive future demand.

2. Europe

Europe emphasizes environmentally sustainable building practices, boosting the adoption of HDPE in water supply, sewage, and industrial applications.

3. Asia-Pacific

Rapid industrialization and urbanization in the Asia-Pacific region drive significant demand for HDPE pipes and fittings, especially in countries like China and India.

4. Middle East and Africa

Demand for HDPE pipes is growing in the Middle East and Africa for water management, agriculture, and industrial applications in challenging environmental conditions.

5. Latin America

Latin America’s agricultural expansion and infrastructure development contribute to HDPE demand, especially in irrigation and water distribution systems.

Future Outlook for HDPE Pipe and Fittings Market

The HDPE pipe and fittings market is projected to grow steadily in the coming years. With ongoing investments in infrastructure, urbanization, and sustainability, HDPE will likely remain a top choice in various sectors. Advancements in production technology and recycling initiatives further support HDPE’s position in the global market.

Conclusion

HDPE pipe and fittings are redefining the piping industry with their durability, adaptability, and environmentally friendly profile. The market outlook for 2024 suggests robust growth, driven by infrastructure development, urbanization, and sustainability goals. As technology advances, HDPE pipes and fittings will become more cost-effective and accessible, making them a preferred solution for industries worldwide.

Frequently Asked Questions (FAQs)

Q1: What makes HDPE pipe fittings better than other materials?

HDPE pipe fittings are highly durable, resistant to corrosion, and environmentally friendly. Their recyclability and long service life make them a cost-effective solution in the long term.

Q2: Can HDPE pipes handle high-pressure applications?

Yes, HDPE pipes handle high-pressure applications, especially in water and gas distribution, where strength and leak-proof performance are essential.

Q3: Are HDPE pipes and fittings easy to install?

HDPE installation requires specialized welding techniques, which may require trained professionals. However, advancements in technology are simplifying installation methods.

Q4: How do HDPE pipes contribute to sustainability?

HDPE pipes are recyclable and have a lower carbon footprint than many traditional materials. Their long service life also reduces the need for frequent replacements, supporting sustainability.

Q5: Which industries benefit most from HDPE pipes and fittings?

HDPE pipes see widespread use in water supply, gas distribution, agriculture, industrial piping, and telecommunications due to their versatility and durability.