Introduction

The global demand for HDPE pipe fittings continues to rise as industries prioritize durable, flexible, and cost-effective piping solutions. Known for their resilience, HDPE pipe fittings serve various sectors, from water and gas distribution to industrial applications. This article dives into the HDPE pipe fittings market, exploring key drivers, industry applications, market trends, and growth prospects, while also shedding light on emerging challenges.

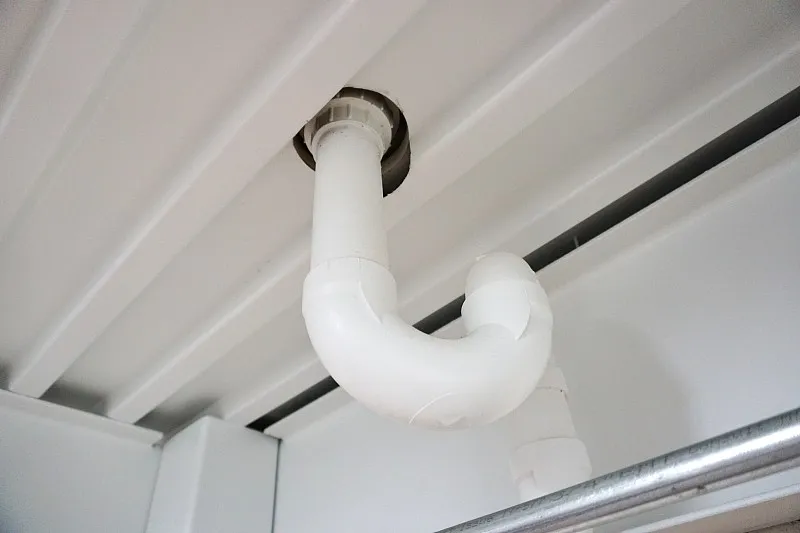

What are HDPE Pipe Fittings?

HDPE pipe fittings are connectors used to join, branch, or terminate HDPE pipes. These fittings provide an efficient and leak-resistant solution that is ideal for handling both low and high-pressure systems. HDPE’s strength, flexibility, and chemical resistance make these fittings a preferred choice across many industries.

Key Benefits of HDPE Pipe Fittings

1. Exceptional Durability

HDPE pipe fittings are resistant to physical impacts, cracking, and environmental stress. Their robustness allows them to function effectively in a wide range of temperatures and environmental conditions.

2. Corrosion and Chemical Resistance

Unlike metal fittings, HDPE fittings are immune to corrosion and many chemicals. This quality makes them suitable for a broad spectrum of applications, including water, gas, and chemical transportation.

3. Sustainability

HDPE fittings are recyclable, which supports global sustainability initiatives. Their long lifespan and lower carbon footprint compared to traditional materials add to their eco-friendly appeal.

4. Cost-Efficiency

HDPE fittings offer significant cost savings over time due to their minimal maintenance needs and long service life. This affordability contributes to their increasing popularity across industries.

5. Flexible and Easy to Install

The flexibility of HDPE materials allows installation of the fittings in challenging terrains, reducing time and labor costs associated with installation.

Types of HDPE Pipe Fittings

The HDPE fittings market includes various types tailored to specific applications:

1. Elbows

Elbows are used to alter the flow direction in a pipe system. They are available in 45 and 90 degrees and are commonly used in water and gas distribution.

2. Tees

Tees are essential for creating branching connections, enabling a primary flow to split in different directions. They are frequently used in irrigation and water supply systems.

3. Couplers

Couplers connect two pipes of the same diameter, providing a seamless and leak-proof connection. These fittings are useful in extending pipelines.

4. Reducers

Reducers allow pipes of varying diameters to connect, adjusting the flow as needed. They are critical in many industrial applications.

5. Flange Adapters

Flange adapters are used to connect HDPE pipes with pipes made of other materials, such as metal, making them highly versatile in mixed-material piping systems.

Major Applications of HDPE Pipe Fittings

HDPE pipe fittings are used across a variety of applications due to their adaptability and durability:

1. Water Supply Systems

HDPE pipe fittings are highly sought after in water supply systems for their leak-proof capabilities, resistance to contamination, and low maintenance needs.

2. Gas Distribution Networks

HDPE’s pressure resistance and flexibility make it suitable for gas transportation systems. HDPE fittings prevent gas leaks and offer a safe, long-term solution for gas distribution.

3. Agricultural Irrigation

HDPE’s resistance to chemicals and corrosion make it an excellent choice for irrigation systems. These fittings facilitate efficient water distribution over large agricultural areas.

4. Industrial Piping

HDPE fittings are used in various industrial sectors, including chemical processing and mining, due to their ability to handle high pressure and resist harsh chemicals.

5. Telecommunication Conduits

HDPE fittings are increasingly used in telecommunications for conduits that protect fiber optic cables, as they shield cables from environmental and physical damage.

Global Market Trends for HDPE Pipe Fittings

The HDPE pipe fittings market is projected to grow significantly in the coming years. Some of the key trends driving this growth include:

1. Growing Infrastructure Development

Emerging economies are investing in infrastructure, and HDPE fittings are becoming a preferred choice for new water, gas, and sewage systems due to their longevity and low environmental impact.

2. Sustainability Initiatives

HDPE’s recyclable nature aligns with the growing emphasis on environmental sustainability. Governments and companies alike are adopting HDPE materials in a bid to lower carbon footprints.

3. Agricultural Expansion

As the global population grows, so does the demand for efficient irrigation systems. HDPE fittings provide an effective solution for water management in agriculture.

4. Technological Advancements

Innovations such as electrofusion and butt-welding technologies have improved the ease of HDPE installation, enhancing its appeal across industries and reducing labor costs.

5. Rising Demand for Safe Water Distribution

With a focus on providing clean, safe drinking water, especially in developing regions, HDPE pipes and fittings offer a hygienic, durable solution for long-term water distribution networks.

Challenges Facing the HDPE Pipe Fittings Market

Despite the advantages of HDPE fittings, certain challenges persist:

1. Fluctuating Raw Material Prices

Since HDPE is a petroleum-based product, fluctuations in oil prices can impact HDPE costs, influencing the market and potentially affecting affordability.

2. Competition from Other Materials

While HDPE has many benefits, it competes with PVC, copper, and other materials. In certain applications, HDPE may be outperformed by these alternatives, which have different performance characteristics.

3. Installation Skill Requirements

Advanced HDPE installation methods, like fusion welding, require specialized skills. This may limit adoption in areas with fewer trained professionals or increase costs where expertise is needed.

4. Environmental Concerns

Although HDPE is recyclable, its petroleum base may raise concerns among eco-conscious consumers and regulators. However, recycling programs and material advancements are addressing this issue.

Regional Analysis of HDPE Pipe Fittings Market

The HDPE pipe fittings market shows varying levels of demand and growth across different regions:

1. North America

North America has a mature HDPE market, with high adoption in water and gas distribution. Increased focus on upgrading aging infrastructure is likely to drive future growth in this region.

2. Europe

Europe’s emphasis on environmental sustainability has bolstered HDPE’s popularity. Stringent regulations on plastic waste management also encourage the adoption of recyclable HDPE fittings.

3. Asia-Pacific

The Asia-Pacific region is experiencing rapid urbanization and infrastructure development, which are primary drivers for HDPE demand. Countries like China and India are major consumers of HDPE pipe fitting.

4. Middle East and Africa

HDPE pipe fittings are in high demand in this region for water supply and gas distribution, owing to the challenging environmental conditions that require durable and corrosion-resistant materials.

5. Latin America

Latin America’s growing agricultural sector drives HDPE adoption for irrigation purposes. The region’s focus on improving infrastructure further supports market growth.

Future Outlook for the HDPE Pipe Fittings Market

The HDPE pipe fitting market is expected to maintain its upward trajectory, driven by ongoing infrastructure projects, sustainable development goals, and technological advancements. As applications increase across diverse industries and efforts to improve HDPE recycling progress, the market will grow steadily over the next decade.

Conclusion

HDPE pipe fittings are transforming piping solutions, offering a robust, sustainable, and cost-effective option across various sectors. As the market continues to expand globally, driven by infrastructure development and sustainability goals, HDPE fittings are likely to remain a key player in industrial and utility applications. Technological advancements make installation easier, and recycling programs address environmental concerns, positioning HDPE fittings for long-term growth.

Frequently Asked Questions (FAQs)

Q1: What makes HDPE pipe fittings environmentally friendly?

HDPE fittings are recyclable, have a long service life, and produce a lower carbon footprint than many traditional materials, making them an environmentally friendly option.

Q2: Can HDPE fittings be used for high-pressure applications?

Yes, HDPE fittings handle high-pressure environments, especially in gas distribution and industrial piping systems.

Q3: How do HDPE pipe fittings compare to PVC fittings?

HDPE is more flexible and resistant to impact and chemicals than PVC, making it suitable for applications requiring durability in extreme conditions. PVC, however, is often less expensive and preferred for low-pressure applications.

Q4: Are HDPE fittings difficult to install?

While HDPE fittings can be more complex to install due to fusion welding methods, advancements in technology have made installation quicker and easier, requiring specialized training.

Q5: What industries benefit most from HDPE pipe fittings?

HDPE pipe fittings see wide use in water supply, gas distribution, agriculture, telecommunications, and industrial piping, offering durability and versatility across various applications.